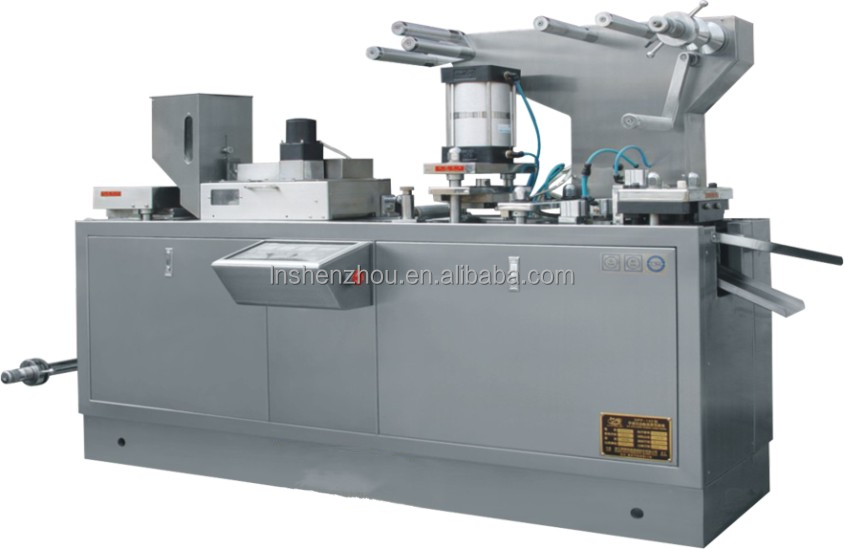

Shenzhou - DPP Automatic Oil Liquid Blister Packaging Honey Chocolate Sauce Cream Syrup Honey Jelly Cup Food Blister Packing Machine Filling&Packing Machine

With strong ability of product research and development, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd ensures new products are launched on a regular basis. Our new product DPP Automatic Oil Liquid Blister Packaging Honey Chocolate Sauce Cream Syrup Honey Jelly Cup Food Blister Packing Machine is a totally new series and has different features. By accurately grasping the pain points of customers, the DPP Automatic Oil Liquid Blister Packaging Honey Chocolate Sauce Cream Syrup Honey Jelly Cup Food Blister Packing Machine developed by us has been supported and praised by the majority of customers in the market. In the future,DPP Automatic Oil Liquid Blister Packaging Honey Chocolate Sauce Cream Syrup Honey Jelly Cup Food Blister Packing Machine will always adhere to the road of quality development, increase the investment in technology and talent introduction, always improve the core competitiveness of the enterprise, to achieve the goal of sustainable development.

| Type: | Blister Packaging Machine | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other |

| Showroom Location: | None | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | Hot Product 2019 |

| Warranty of core components: | 1 Year | Core Components: | Motor |

| Condition: | New | Application: | Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware |

| Automatic Grade: | Automatic | Driven Type: | Electric |

| Voltage: | 380V/50Hz 220V/60Hz | Place of Origin: | China |

| Brand Name: | LYSZ | Weight: | 460 KG |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

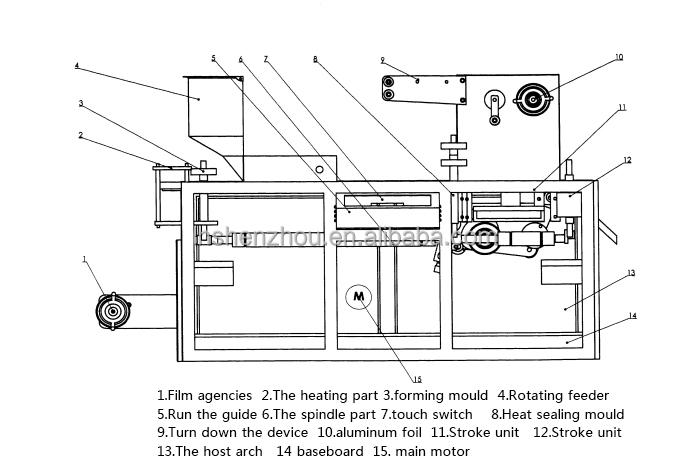

* It allows forming thermoplastic and cold forming materials (Alu-Alu).

* It stands out for its simple operation, high reliability and compact design. Its main structure is made of stainless steel.

* Automation by PLC and operation through touch screen control panel.

* It has pneumatic drives, which lend it high robustness and low maintenance.

* It is suggested for R&D departments, considering that its easy operation and maintenance makes it user-friendly to personnel that are not familiar with the use of blister machines.

DPP Automatic Blister Packaging Machine | ||||||

DPP-80 | DPP-140 | DPP-250 | ||||

Blanking frequency | PVC-AL: 10-40 times/min AL-AL: 10-30 times/min | PVC-AL: 10-40 times/min AL-AL: 10-30 times/min | PVC-AL: 10-40 times/min AL-AL: 10-30 times/min | |||

Adjustable scope of feed travel | 30-100mm(adjustable) | 30-120mm(adjustable) | 30-140mm(adjustable) | |||

The max forming area and depth | 120mm×90mm×20mm | 150mm×120mm×26mm | 240mm×130mm×26mm | |||

Wrapper: ALU | Length: 130mm, thickness: 0.02-0.035mm | Length: 160mm, thickness: 0.02-0.035mm | Length: 250mm, thickness: 0.02-0.035mm | |||

Wrapper: PVC | Length: 130mm, thickness: 0.25-0.5mm | Length: 160mm, thickness: 0.25-0.5mm | Length: 250mm, thickness: 0.25-0.5mm | |||

Wrapper: PTP | Length: 130mm, thickness: 0.02-0.035mm | Length: 160mm, thickness: 0.02-0.035mm | Length: 250mm, thickness: 0.02-0.035mm | |||

Wrapper:Dialysis paper | Length:130mm, specification:50-100 gram | Length:160mm, specification:50-100 gram | Length:250mm, specification:50-100 gram | |||

Power of forming heating | 1.5KW | 2.4KW | 3KW | |||

Power of sealing heating | 1.5KW | 2.4KW | 3KW | |||

Main motor power | 0.75KW | 1.5KW | 1.5KW | |||

Machine Voltage | 380V/220V 50Hz | |||||

Capacity of air compressor | ≥0.2m3/min Pressure: 0.4~0.6MPa | ≥0.2m3/min Pressure: 0.5~0.7MPa | ≥0.2m3/min Pressure: 0.5~0.7MPa | |||

Overall dimension | 2070mm×650mm×1060mm | 2350×580×1500 mm | 3100×670×1650mm | |||

Weight | 560Kg | 800KG | 1500KG | |||

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian