Shenzhou - LWS 3 Phase Centrifuge , High Rigidity Centrifuge Industrial Equipment Centrifuge & Separator

After years of in-depth research,we has successfully developed a brand-new LWS 3 Phase Centrifuge , High Rigidity Centrifuge Industrial Equipment.Currently, this technology is the industry leader.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd offers an exceptional quality range of Separation Equipment. The product is endowed with stable and multi-functional performance. It is mainly used in the application field(s) of Separation Equipment. To keep ourselves ahead of other competitors, we will strive forward to improve our R&D strength and technology ability. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd hope that one day we will develop more and better products without relying on others' technologies.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | Model | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | Thailand, Sri Lanka | Certification: | GMP/CE |

Product Description

Horizontal Large Capacity PLC Control Municipal Industrial Wastewater Centrifuge

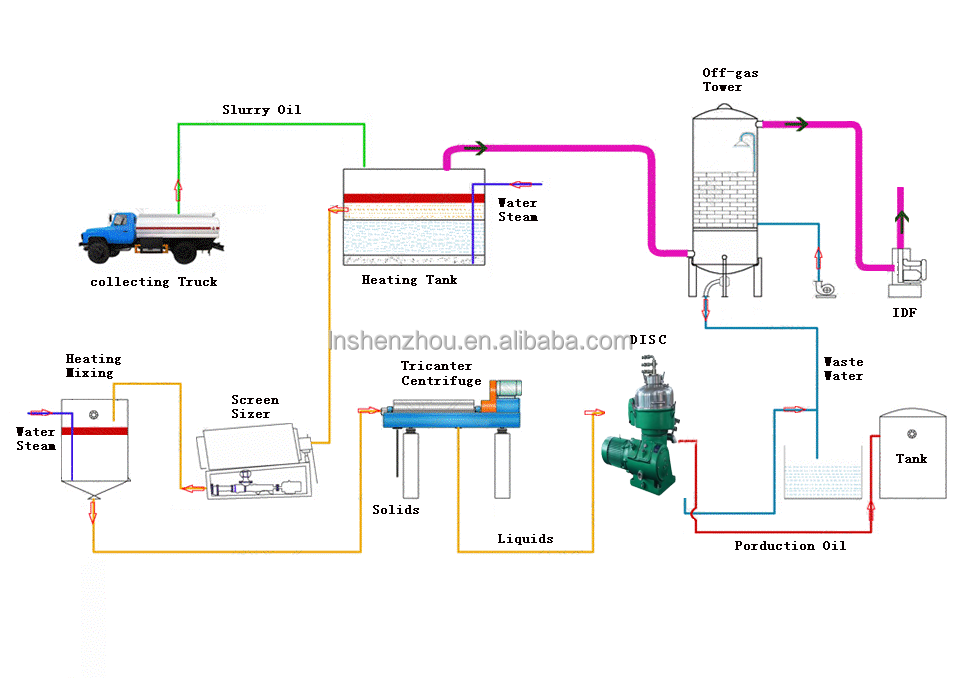

I. Details of Water Treatment field

The impurities such as glass and braids in the biochemical sludge from the sludge tank is pulverized and removed. The sludge pump sends the sludge (concentration 0.5~4% or higher) into the centrifuge, and the fully automatic flocculant dosing device adds continuously PAM flocculant solution (concentration 1~3‰) into the feed pipe through the dosing pump for flocculation in the feed pipe and in the vicinity to produce flocculus to be sent into the centrifuge. The dehydrated mud cake is discharged from the drum by a centrifuge, and transported to the outside through the screw conveyor.

The dehydration system is widely used for oxidation ditch, AB, A/O, A2/O, SBR, MBR, anaerobic fermentation, and other processes, as well as urban domestic sewage, municipal sewage, landfill leachate, urban tap water, purified water, and some industrial wastewater of conventional sewage treatment processes. Solid-liquid separation is achieved by a high-performance DE type two-phase high-efficiency centrifuge.

Modern water purification and sewage treatment processes, increasingly strict emission standards, and subsequent treatment of dewatered mud cakes, whether stacked, dried or incinerated, have set higher requirements for key equipment of excess sludge treatment.

Brief Introduction

Three phase industrial centrifuge for palm oil refinery machine with palm oil disc separator for continuous separation of solids from liquids such as thickening and dewatering sludge, suspensions with granular solids, clarification of liquids, separating starch, etc. We provide a broad range of DECANTER sizes.

Main Characteristics

1.Continuous working,spiral discharging,high capacity.

2.Controlled by two motors,rovolving drum can be adjustable two stage separately.

3.Wide applicability for chemical,oil,foodstuff,pharmacy industries and green industry in which solid-liquid separation is

required.

4.Suitable for various products,capable for separating wide ranging solid phase grains(0.002-2mm),especially when separating solid phase has different size grains

Three phase industrial centrifuge for palm oil refinery machine with palm oil disc separator for continuous separation of solids from liquids such as thickening and dewatering sludge, suspensions with granular solids, clarification of liquids, separating starch, etc. We provide a broad range of DECANTER sizes.

Main Characteristics

1.Continuous working,spiral discharging,high capacity.

2.Controlled by two motors,rovolving drum can be adjustable two stage separately.

3.Wide applicability for chemical,oil,foodstuff,pharmacy industries and green industry in which solid-liquid separation is

required.

4.Suitable for various products,capable for separating wide ranging solid phase grains(0.002-2mm),especially when separating solid phase has different size grains

Material Choice

According to users' requirement,the product contact parts can be made of austenite stainless Steel(321,316L...904L,C2205),Haynes alloy titanic alloy or other anti-erosion materials

According to users' requirement,the product contact parts can be made of austenite stainless Steel(321,316L...904L,C2205),Haynes alloy titanic alloy or other anti-erosion materials

Structure Choice

1. Methods of lubrication:

A.Grease lubrication

B.Circular forced lubrication

2. Number of helical blade head is selectable within single head helix,double head helix or multiple head helix

3. Helix surface is coated with high hardness alloy

1. Methods of lubrication:

A.Grease lubrication

B.Circular forced lubrication

2. Number of helical blade head is selectable within single head helix,double head helix or multiple head helix

3. Helix surface is coated with high hardness alloy

Scope of application:

II. Centrifuge characteristics

Unparalleled equipment investment costs and later-stage operation costs

For water purification plants and sewage treatment plants, high-performance water treatment centrifuge is an ideal solution, which is highly adaptable to sludge and has greater processing capacity at low concentration (SS 0.5). In the case of low concentration (SS 0.5%), it is not necessary to equip a concentrator to realize the dehydration function, which satisfy the requirements of the process for integrated concentration and dehydration.

Diversified models, wide selection range, and complete engineering project

Whether your water treatment plant is in a scale of 5,000 tons/day or less or you are a large-scale environmentally-friendly

company with a scale of millions of tons per day, you can find the right model configuration in a high-performance water treatment centrifuge. Meanwhile, the turnkey project (water introduction and discharging, cable laying, mud cake conveying, equipment infrastructure construction, and equipment installation) for dehydration room can be implemented to solve the disconnection between construction and suppliers, and to eliminate the worries of customers.

Modular design, easy to operate

Our design philosophy: To lower the requirements on the skills, educational level, and labor intensity of operators, and realize one-button start and stop of the control system, fault self-diagnosis, and safety self-protection.

Operator configuration and labor intensity

The high-performance centrifuge is an automatic and continuous working mode for feeding-separating-slag (liquid) discharging. The whole process requires no human intervention. Multiple sets of equipment require only one inspector (in conjunction with other positions). Unlike the plate-and-frame filter, it does not require manual cutting in the sludge discharging process, greatly alleviating the labor intensity of operators.

Unparalleled equipment investment costs and later-stage operation costs

For water purification plants and sewage treatment plants, high-performance water treatment centrifuge is an ideal solution, which is highly adaptable to sludge and has greater processing capacity at low concentration (SS 0.5). In the case of low concentration (SS 0.5%), it is not necessary to equip a concentrator to realize the dehydration function, which satisfy the requirements of the process for integrated concentration and dehydration.

Diversified models, wide selection range, and complete engineering project

Whether your water treatment plant is in a scale of 5,000 tons/day or less or you are a large-scale environmentally-friendly

company with a scale of millions of tons per day, you can find the right model configuration in a high-performance water treatment centrifuge. Meanwhile, the turnkey project (water introduction and discharging, cable laying, mud cake conveying, equipment infrastructure construction, and equipment installation) for dehydration room can be implemented to solve the disconnection between construction and suppliers, and to eliminate the worries of customers.

Modular design, easy to operate

Our design philosophy: To lower the requirements on the skills, educational level, and labor intensity of operators, and realize one-button start and stop of the control system, fault self-diagnosis, and safety self-protection.

Operator configuration and labor intensity

The high-performance centrifuge is an automatic and continuous working mode for feeding-separating-slag (liquid) discharging. The whole process requires no human intervention. Multiple sets of equipment require only one inspector (in conjunction with other positions). Unlike the plate-and-frame filter, it does not require manual cutting in the sludge discharging process, greatly alleviating the labor intensity of operators.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

Working Principle

III. Technical characteristics of the centrifuge

Not only equipment manufacturer but also system engineering service provider

With strong technical strength and rich engineering experience, we are fully qualified for the turnkey project of the sludge

dewatering room. We are also willing to recommend the design layout of the sludge dewatering room for owners and design institutes.

Eddy current type spiral outlet

The outlet of the screw conveyor adopts a vortex type to accelerate the entry of materials into the rotating drum, thereby

reducing the disturbance of the discharged materials to the formed solid phase layer and improving the processing capacity. In the industry of flocculant, it can effectively reduce the shearing effect of the discharge hole on the floccules under the high-speed discharging state, so as to reduce the consumption of chemical agent.

BD board technology

The screw conveyor adopting BD board technology is the most advanced for reducing the water content and improving the solid recovery rate of activated sludge (organic matter ≥ 40%). The technology has the following advantages:

• Increase the depth of the liquid layer, the effective settlement area, and the processing capacity of the centrifuge;

• Reduce the moisture content of the sediment under the action of spiral high-pressure extrusion;

• Improve solid recovery rate and make the clear liquid clearer;

• Save the consumption of chemical agent and cut down equipment operating cost;

• Compared with the common centrifuges of the same separation performance, it is lower in operating speed and requires less power consumption.

More economical in equipment investment and later-stage operation

Goal: Minimum equipment operation, maintenance and repair costs;

We are committed to creating the best quality and most cost-effective China-made centrifuge brand. We recognize that stable operation of equipment is the guarantee of greater benefits for customers, and outstanding suppliers and modern processing equipment are the basic guarantee for quality centrifuges. Advanced and unique technology is the guarantee to reduce operating cost, in addition to high-quality wear resistance, eddy current type spiral outlet, circular arc slag outlet, special spiral structure, advanced electrical control technology, etc.

High performance wear-and corrosion-resistant cemented carbide

There are inevitably small hard particles and impurities such as sand, glass, and metal in sewage. If the centrifuge does not adopt a reliable wear-resistant configuration, its service life and operational stability will be greatly affected. The

wear-resistant solution is completely targeted. According to the material characteristics (pH value, corrosive substance, solid particle size hardness, etc.), cemented carbide or ceramic can be selected, and the cemented carbide can be either YG6, YG8, or various modified tungsten-cobalt alloys with the hardness of 89~93 (HRA), which can fully meet the application fields of the centrifuge.

Not only equipment manufacturer but also system engineering service provider

With strong technical strength and rich engineering experience, we are fully qualified for the turnkey project of the sludge

dewatering room. We are also willing to recommend the design layout of the sludge dewatering room for owners and design institutes.

Eddy current type spiral outlet

The outlet of the screw conveyor adopts a vortex type to accelerate the entry of materials into the rotating drum, thereby

reducing the disturbance of the discharged materials to the formed solid phase layer and improving the processing capacity. In the industry of flocculant, it can effectively reduce the shearing effect of the discharge hole on the floccules under the high-speed discharging state, so as to reduce the consumption of chemical agent.

BD board technology

The screw conveyor adopting BD board technology is the most advanced for reducing the water content and improving the solid recovery rate of activated sludge (organic matter ≥ 40%). The technology has the following advantages:

• Increase the depth of the liquid layer, the effective settlement area, and the processing capacity of the centrifuge;

• Reduce the moisture content of the sediment under the action of spiral high-pressure extrusion;

• Improve solid recovery rate and make the clear liquid clearer;

• Save the consumption of chemical agent and cut down equipment operating cost;

• Compared with the common centrifuges of the same separation performance, it is lower in operating speed and requires less power consumption.

More economical in equipment investment and later-stage operation

Goal: Minimum equipment operation, maintenance and repair costs;

We are committed to creating the best quality and most cost-effective China-made centrifuge brand. We recognize that stable operation of equipment is the guarantee of greater benefits for customers, and outstanding suppliers and modern processing equipment are the basic guarantee for quality centrifuges. Advanced and unique technology is the guarantee to reduce operating cost, in addition to high-quality wear resistance, eddy current type spiral outlet, circular arc slag outlet, special spiral structure, advanced electrical control technology, etc.

High performance wear-and corrosion-resistant cemented carbide

There are inevitably small hard particles and impurities such as sand, glass, and metal in sewage. If the centrifuge does not adopt a reliable wear-resistant configuration, its service life and operational stability will be greatly affected. The

wear-resistant solution is completely targeted. According to the material characteristics (pH value, corrosive substance, solid particle size hardness, etc.), cemented carbide or ceramic can be selected, and the cemented carbide can be either YG6, YG8, or various modified tungsten-cobalt alloys with the hardness of 89~93 (HRA), which can fully meet the application fields of the centrifuge.

Reduce the moisture content of the sediment under the action of spiral high pressure extrusion

High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong centrifugal force, high-torque screw extrusion force (pushing torque), and ultra-long solid particle dehydration length. The centrifuge can generate centrifugal force exceeding thousands of G, 30 ~ 50% higher than the screw pushing torque of common centrifuges. The screw pusher torque, and the drum dehydration length is 10 ~ 20% longer than that of common centrifuges.

High torque involute planetary gear differential

The ultra-high pushing torque requires a high-torque involute planetary gear differential as the foundation. The differential

equipped on the centrifuge features high torque, high speed, low heat generation, and excellent heat dispersion, which ensure that the centrifuge can be used for a long time and stably.

High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong centrifugal force, high-torque screw extrusion force (pushing torque), and ultra-long solid particle dehydration length. The centrifuge can generate centrifugal force exceeding thousands of G, 30 ~ 50% higher than the screw pushing torque of common centrifuges. The screw pusher torque, and the drum dehydration length is 10 ~ 20% longer than that of common centrifuges.

High torque involute planetary gear differential

The ultra-high pushing torque requires a high-torque involute planetary gear differential as the foundation. The differential

equipped on the centrifuge features high torque, high speed, low heat generation, and excellent heat dispersion, which ensure that the centrifuge can be used for a long time and stably.

Fluids Outlet position Alloy wear plate

CIP washing system

The fully automatic control system is equipped with a CIP washing system, which can effectively solve the problem that it is not completely cleaned during the shutdown process and effectively avoid the equipment troubles caused by artificial factors.

Humanized centrifuge configuration

1.Spiral bearing (in the drum, concealed) lubrication technology: the lubricant is filled from the outside of the hood.

2,The hood adopts a hinged opening structure and is equipped with a high-pressure gas strut to assist the opening.

Variable pitch technology

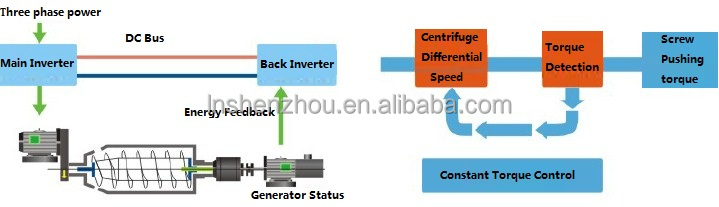

Constant torque control technology

The constant torque control of the centrifuge is the most advanced control mode in the world. The real-time monitoring of the actual output torque of the constant torque variable frequency motor through the high-performance auxiliary inverter is compared with the set torque value, and PID is used to adjust the material pushing speed of the screw conveyor in real time. The centrifuge can achieve continuous, stable, and economic operation.

CIP washing system

The fully automatic control system is equipped with a CIP washing system, which can effectively solve the problem that it is not completely cleaned during the shutdown process and effectively avoid the equipment troubles caused by artificial factors.

Humanized centrifuge configuration

1.Spiral bearing (in the drum, concealed) lubrication technology: the lubricant is filled from the outside of the hood.

2,The hood adopts a hinged opening structure and is equipped with a high-pressure gas strut to assist the opening.

Variable pitch technology

Constant torque control technology

The constant torque control of the centrifuge is the most advanced control mode in the world. The real-time monitoring of the actual output torque of the constant torque variable frequency motor through the high-performance auxiliary inverter is compared with the set torque value, and PID is used to adjust the material pushing speed of the screw conveyor in real time. The centrifuge can achieve continuous, stable, and economic operation.

Production workshop

Screw production1

Screw production2:

.

High speed dynamic balance detection1

High speed dynamic balance detection2

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap