olive oil centrifuge separator from Shenzhou compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Shenzhou summarizes the defects of past products, and continuously improves them. The specifications of olive oil centrifuge separator from Shenzhou can be customized according to your needs.

Ø Description of olive oil centrifuge separator from shenzhou Group

The fusion, decanting and separation process is the core step of the entire process. Horizontal ribbon mixer, decanter centrifuge and disc centrifuge are key to ensuring the oil yield and oil quality-According to the process requirements, experimental data and engineering application examples,2-phase decanter centrifuge or 3-phase horizontal decanter centrifuge and self-cleaning disc separator are usually used, and the oil yield can reach 15%.

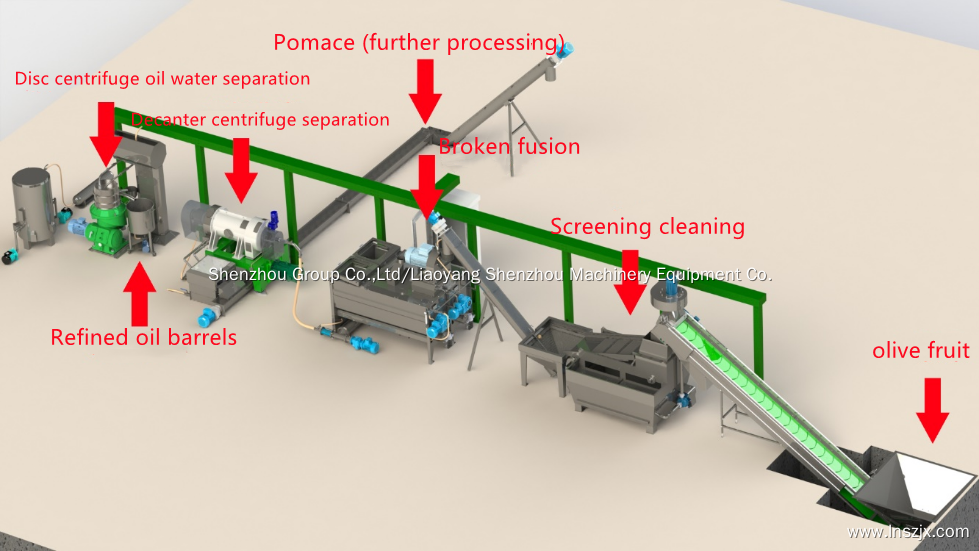

According to the product characteristics and production process, the main steps of the process design are:(1) defolate (2) washing (3)crushing (4) fusion ,(5) decantation,(6) separation,(7)storage (8) filling and packing

1. Defolate: The olive fruit after picked is transferred throuah the belt conveyor equipped with a wind sorter to remove leaves,to avoid chlorophyll oxidation and affect the quality of the oil. Branches and leaves separated fomfruit by fan.

2.Washing: Wash the fruit with circulating water to remove dust,sand and a small amount of leaves. Usually,2 tons of water wash 5 tons of fruit.

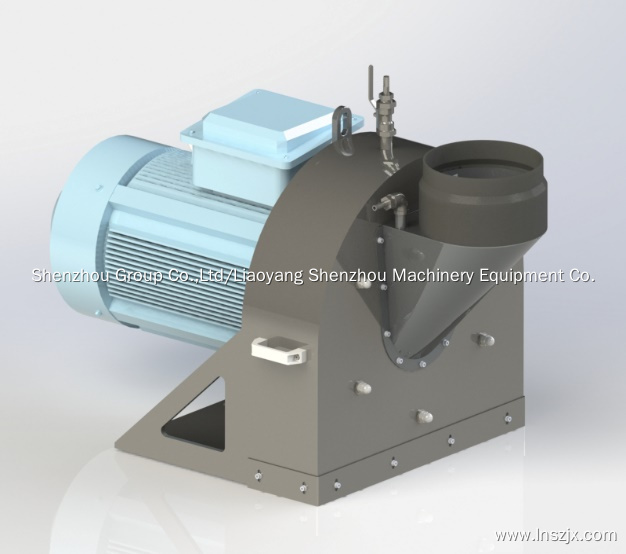

3. Crushing : Crush the washed olive fruit to get fruit pulp by a hammer mill. The mesh size is about 6 mm and the beating speed is about 2500-3000 rpm.

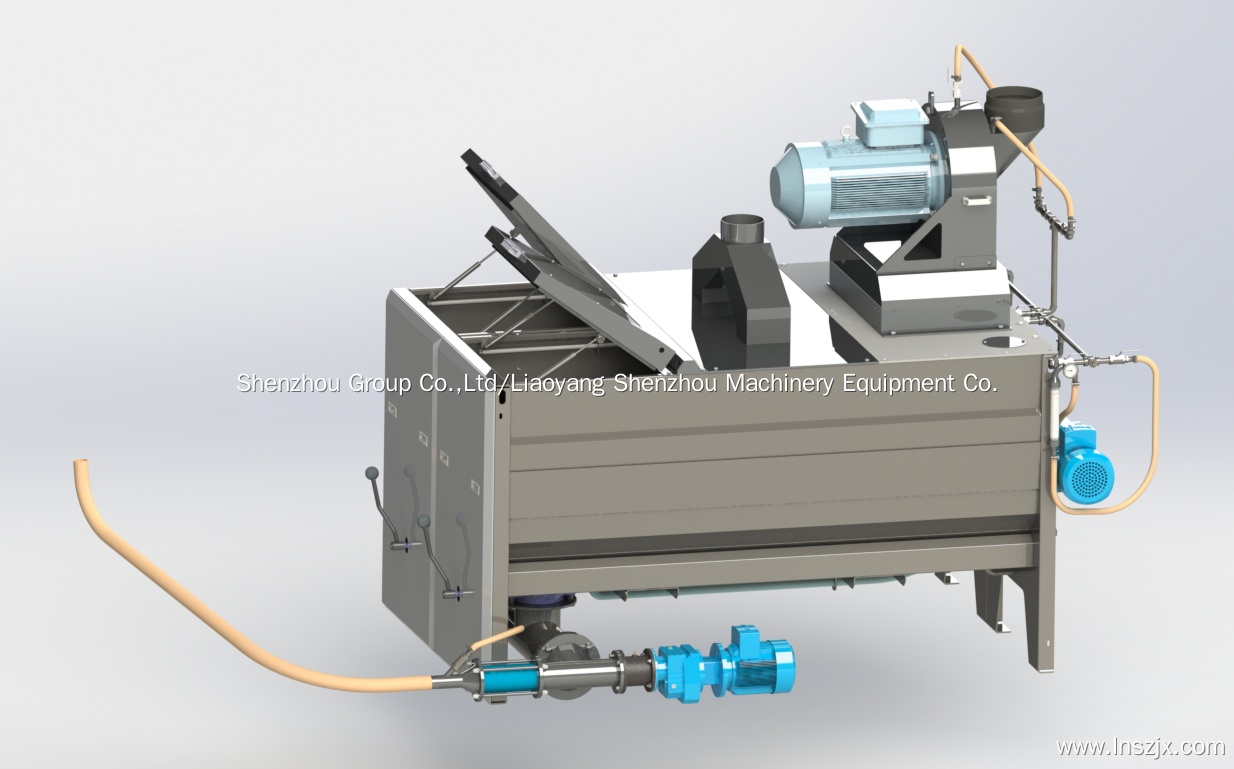

4.Fusion: The crushed pulp is transferred to a horizontal ribbon mixer through a screw pump for mixing,and the oil droplets are formed by stirring with a ribbon mixer. The better mixing time is about 30 minutes,temperature about 30 degrees and the crusher rotation speed is 30-50 revolutions.The horizontal mixer is equipped with jacket for water cooling.

5.Decanting: The blended oil water and pomace are transported by a screw pump to the decanter centrifuge for oil,water and pomace separation.Two or Three-phase separation decanter and the vertical disc centrifuae are usually selected according to the process requirements. The three-phase separation process requires to add a larae amount of process water and finally separate the oil waste water and pomace: finally the amount of waste water is larae: the two-phase separation directly separates the pulp into oil and pomace,no need to add water,but the water content of the pomace is high,more than 60%,further separation is required.

6. Separation: The separated oil phase also contains a small amount of water,which is required further separation by a vertical high-speed centrifuge, and the centrifuge speed is about 6600-8000 rpm. About 10-15% of water is added during the separation.

7. Storage: The centrifugally separated oil is pumped into big stainless steel storage tanks for storage to avoid light and heat,usually the stainless steel storage tank is filled with nitrogen gas and olive oil is stored at a constant temperature and filled N2 state.

8. Filling: The oil in the tank periodically releases a small amount of water and oil foot. Then it is dspensed into glass bottles and sealing labeling and packing etc, for sale in market.

Ø Overview of olive oil centrifuge separator from Shenzhou

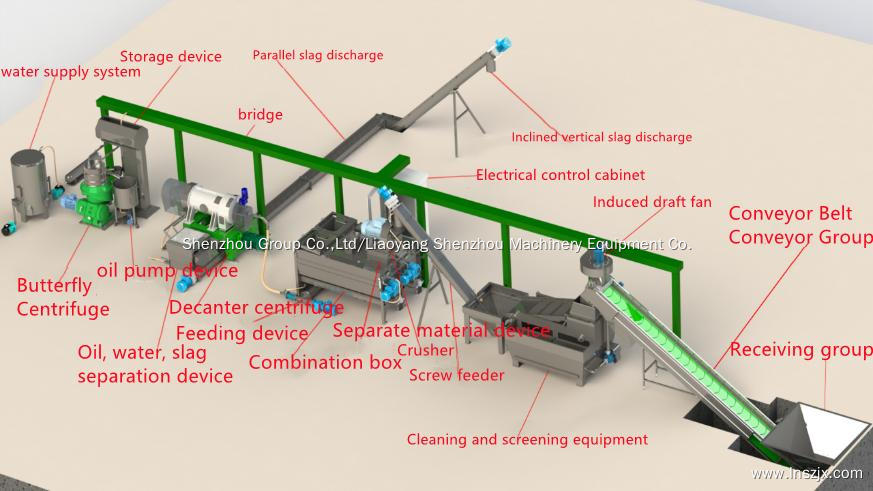

GlY750 intelligent virgin olive production line, with LWS350 series decanter centrifuge and DHG315 dish separator as the core equipment, covers the whole process from olive fruit sorting and leaf removal, cleaning, crushing, fusion, separation, slagging, purification until the finished virgin olive oil into the tank.

All equipment in the production line is designed and manufactured with modular units to ensure the quick interchangeability and universality of each unit. Based on the fusion unit of about 750kg olive fruit per process cycle, users can quickly and conveniently assemble and customize their own production lines.

The whole line uses centralized control + field operation combined control mode, to ensure the safety of the system, convenient and quick operation。

Ø :Belt Feeder and air separator

It provides the receiving group for the fresh fruit input production line, and conveys the fresh fruit to the next cleaning process through the conveyor belt. At the same time, the belt conveyor is also the connecting device between the production workshop and the feeding workshop.

The whole machine is welded and manufactured by high quality 304 stainless steel. The conveyor belt is made of food-specific white PU baffle belt.

Power drive: Precision RV reducer, NMRV075-20; Supporting motor: 1.5kw driven by inverter, stepless speed regulation.

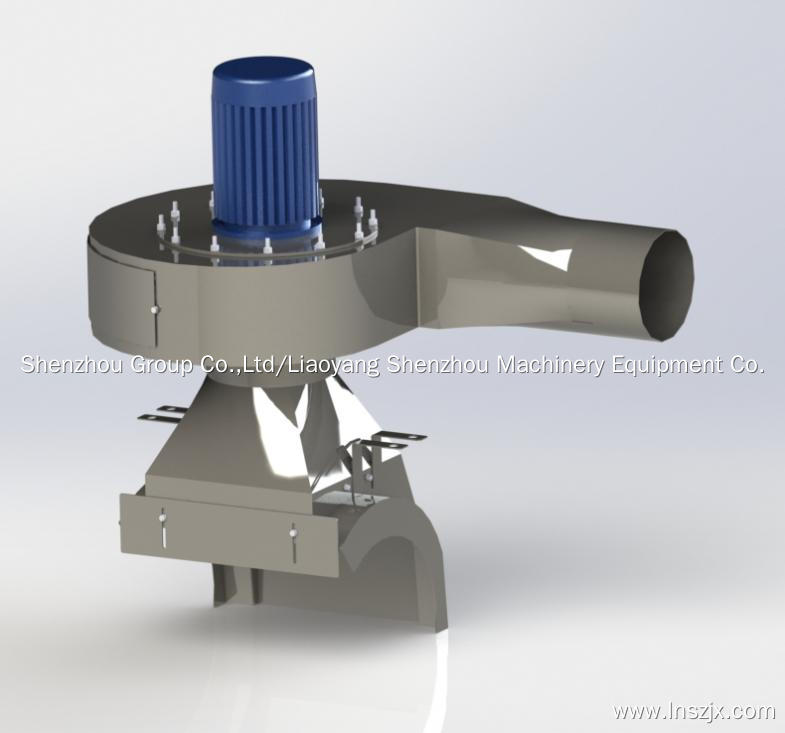

◇Induced fan:

◇Cleaning and screening equipment

◇Device for conveying materials

◇Crusher

The clean fresh fruit is broken into olive pulp by the high-speed rotating hammer, and enters the fusion box directly or through the fusion feeding screw or pump.

Responsible for sending the cleaned fresh fruit to the crusher.

The whole machine is welded and manufactured by high quality 304 stainless steel.

The fresh fruit sent by the belt conveyor is cleaned by surfing to remove the impurities and residual sediment attached to the surface of the fresh fruit. The washed fresh fruits are sent to the lifting process after being drained.

○ After washing, the fresh fruits are shaken on a vibrating sieve and drained.

The cleaning water is recycled, and the water tank adopts an independent partition structure. The cleaned water is precipitated and filtered in the cleaning area and then enters the water purification area for recycling.

It is installed at the discharge position at the top of the belt conveyor, and uses the strong negative pressure generated by the high-speed fan to absorb the mixed branches and leaves in the fresh fruit flow, and discharge it to the fixed collection position through the pipeline.

The whole machine is welded and manufactured by high quality 304 stainless steel. Installed power: 2.2kw

◇Distributing device:

The crushed olive pulp directly enters the fusion box in the combination line of 2 boxes, and in the combination line of more than 3 boxes, the pulp needs to enter the corresponding empty box through the feeding screw or pump.

◇Combination box:

The fruit pulp undergoes a full fusion process for 30 to 50 minutes in the box. After the fusion and agglomeration of the oil droplets are completed, it can enter the decanter centrifuge for separation.

When the fusion box is working, the stirring screw keeps rotating and stirring to ensure that the pulp in the box is fully mixed and the temperature is uniform. The fusion box is a double-layer structure, and the outer layer is a hot water layer, which improves the constant temperature of the fruit pulp fusion in the box.

◇Device for conveying materials

The fused fruit pulp is first sent to the horizontal screw feeding pump by the fusion discharging screw, and then sent to the next process.

The fusion discharging screw is connected with the fusion box body through the discharge port of the box body, and the discharge disc valve is arranged in the middle to control the opening and closing.

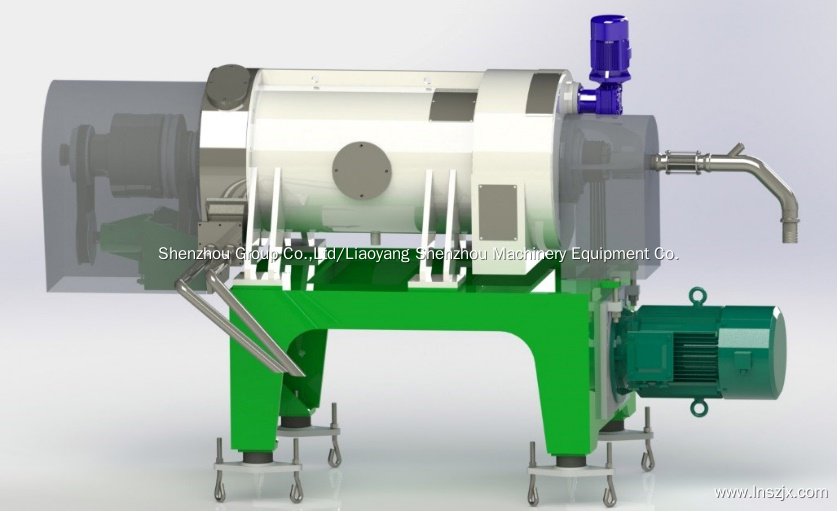

◇Decanter centrifuge: ◇ Horizontal slag discharge: ◇ Oblique vertical slag discharge:

◇Oil, water and slag separation device:

Fruit pulp into the horizontal screw centrifuge, the motor drives the drum and blade, through the differential drum and blade will form a difference in speed so as to separate the oil and water in fruit pulp and fruit residue. The separated oil and water flow into the vibrating screen device will contain the participation of fruit residue further screening out and the screened oil and water through the screw pump into the purification device; The separated pomace and sifted pomace are discharged through the screw discharging device for other purposes.

The oil and water separated from the decanter centrifuge are conveyed into two separate boxes in the receiving tank through separate channels. A vibrating filter screen is arranged between the outlet of the decanter centrifuge and the receptacle box of the receiving tank, which is used to intercept and collect a small amount of residue in the oil and water to the discharge channel.

The blended pulp is separated at high speed into the horizontal screw centrifuge, and the fruit dregs, water and oil are discharged from the respective channels. Decanter centrifuge is equipped with professional vibration detection system and running speed tracking system to ensure the safe and reliable operation of the system.

◇Storage device

The oil and water separated by the horizontal decanter centrifuge are processed by the oil, water and slag separation device, transported to the storage device through the screw pump, and then through the dish separator for further purification.

The whole machine adopts high quality 304 stainless steel welding and manufacturing.

◇Disc separator, oil pump device

The oil in the oil storage tank is mixed with water in a certain proportion and then enters the disc centrifuge to further separate the remaining impurities in the oil to obtain clean and pure virgin olive oil.

。

In order to ensure the quality of olive oil, the decanter centrifuge must be thoroughly cleaned every time it is shut down to avoid material residue in the drum.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1