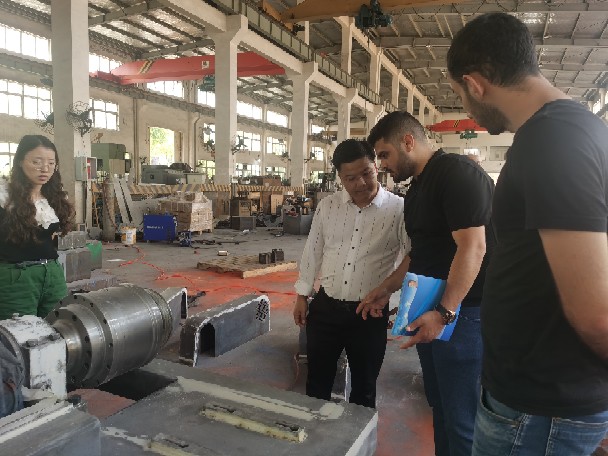

Turkey Customers Highly Praise Shenzhou' Technology And buy1 Pcs LWS520 Three Phase Decanter Centrifuge

Turkey Customers Highly Praise Shenzhou' Technology And Placed 1 Pcs LWS520 Three phase Decanter Centrifuge

Türkiye's crude oil customers visited our factory and ordered a LWS520 three-phase horizontal spiral centrifuge. Used for separating crude oil, water, and sludge

The LWS520 three-phase decanter centrifuge produced by our company is a specialized equipment for separating crude oil, water, and sludge. The rotary drum adopts a centrifugal casting structure, and the separation breaks the traditional separation structure. It adopts a centripetal pump structure for better separation effect.

Product Description

LWS520 three-phase centrifuge can continuously feed, separate and discharge at full speed. It has the characteristics of compact structure, easy sealing, stable operation, low noise, large processing capacity, low energy consumption, high degree of automation, low labor intensity, convenient operation and maintenance, wide application range and so on. For some materials that are difficult to separate, in addition to taking corresponding adjustment measures for the separat-ed materials themselves, the centrifuge can also be adjusted and improved accordingly:

1. Increase the length diameter ratio;

2. Adjust the rotating speed of the drum;

3. Adjust the differential speed between the drum and the discharge screw;

4. Change the half cone angle of the drum cone section and adopt multi cone angle sorew;

5. Adjust the overflow radius of the liquid phase outlet;

6. Change the number of screw heads and screw lifting angle of discharge screw;

7. Add BD plate structure;