Shenzhou - decanter centrifuge food olive industry Centrifuge & Separator

Except for the wisdom of intelligent and hard-working employees, the utilization of high-end technologies also plays an important role in the manufacturing process of the decanter centrifuge food olive industry.The product is geared towards the field(s) of Separation Equipment.

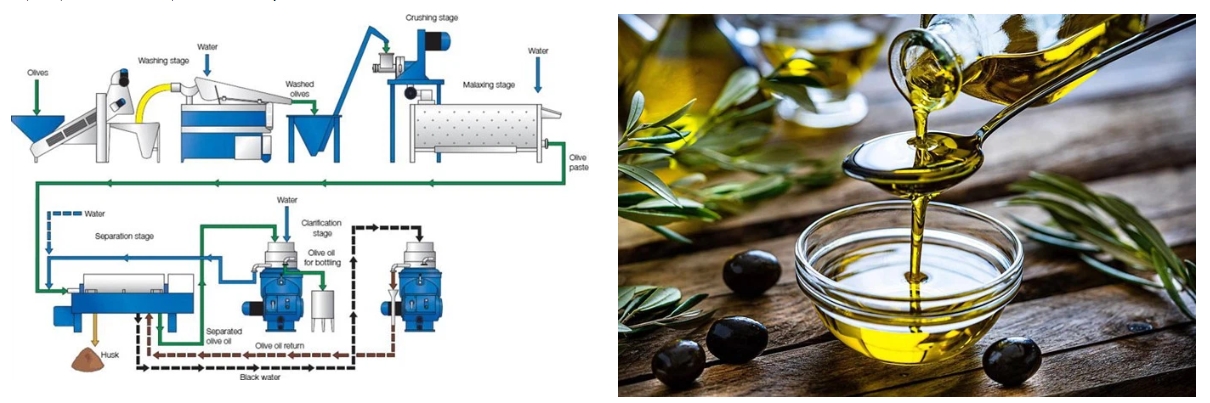

In order to better purification of olive oil, Shenzhou has specially developed a food-grade olive oil three-phase centrifuge to realize 360 degree automatic feeding and discharging, separation and extraction of olive oil. Meanwhile, it can help enterprises to achieve environmental standards and food safety standards in production.

Product Details

3 Phase Horizontal Tricanter centrifugedetermined by particle size,particle shape,difference in density between solids and liquids as well as the iviscosity Decanter centrifuge is suitable for solid-phase dewatering, liquid-phase clarification and separation, liquid-liquid-solid three phase separation and size-grading of various suspensions with solid-phase particle sizes of 0.005-15mm, consistency of 1-40% and temperature of ≤ 100°C. It is used for oil-water-solid separation , Have good performance in olive oil , coconut oil ,palm oil avocado oil production line .

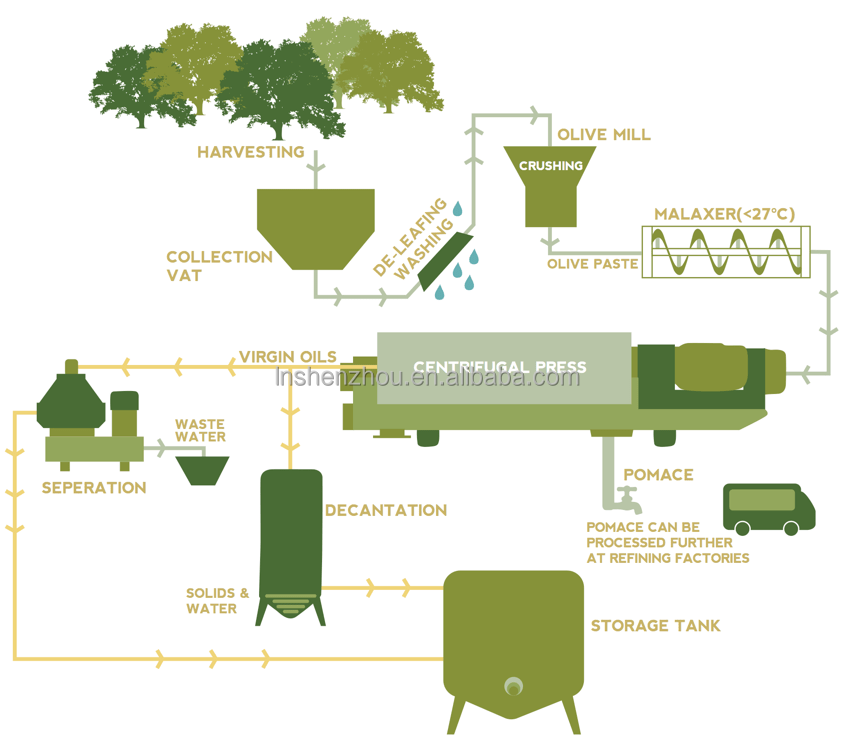

How Does Shenzhou Decanter Centrifuge Work?

The operating principle of a decanter centrifuge is based on separation via centrifugal force. Naturally, a component with a higher density would fall to the bottom of a mixture, while the less dense component would be suspended above it. A decanter centrifuge increases the rate of settling through the use of continuous rotation, producing a g-force equivalent to between 1000 and 4000 G's. This reduces the settling time of the components by a large magnitude, whereby mixtures previously having to take hours to settle can be settled in a matter of seconds using a decanter centrifuge. This form of separation enables more rapid and controllable results.

With a 3 phase decanter centrifuge, it is possible to separate 3 phases from each other in one process step only. e.g. Oilve Oil, two liquids(oil and water) which cannot be mixed because of different densities are separated from a solids phase. The heavy liquid (water) collects in the middle between the oil and the solids layer. Thus the two liquids separated from each other can be drawn off from the decanter. The solids are transported via the scroll to the discharge openings as it happens also in 2-phase separation.

During the extraction of olive oil or palm oil, the plant constituents (seeds, fruits, skins) are pressed and milled. The oil they contain is collected, purified and processed in several processes by means of centrifugal refining and separation technology. Extraction of seed oil or press oil focusses on maximum yield at the same time as careful treatment. Tailor-made Shenzhou decanters and separators help to optimise the overall process decisively.

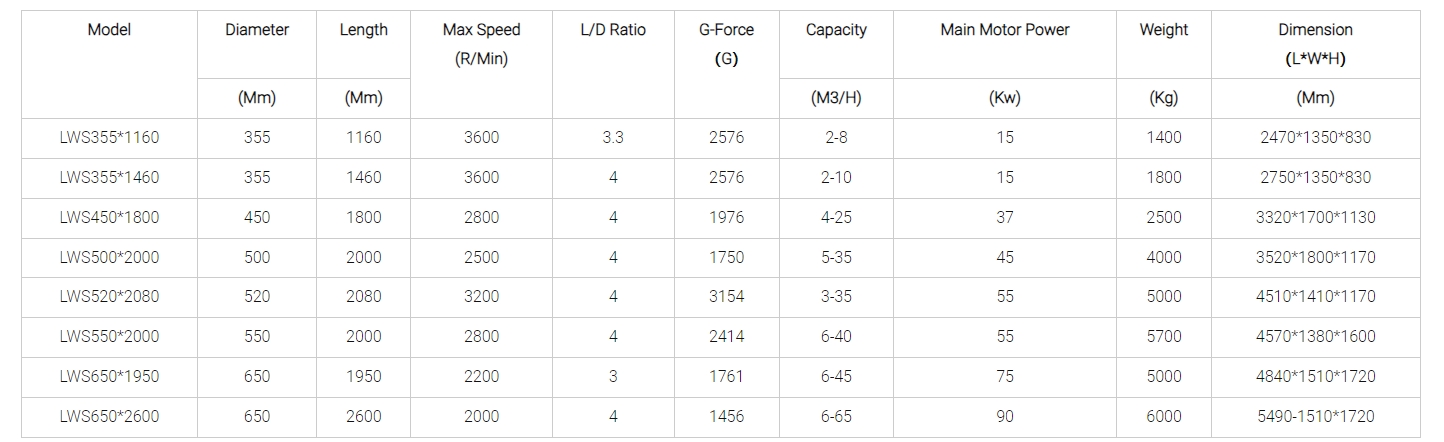

Technical Parameter

Decanter Configuration

Configuration

1.Motor: Dual motor and Dual inverter.

2.Bearing is SKF/NSK

3.The PLC touch screen (Siemens).

4. Run mode: 24 hours continuously.

7. Starting and driving way: inverter

8. Vibration sensors: when the machine have problem. The instrument will automatically alarm and make the machine stop.

9. Quick sensors is can show the running speed.

10. Feeding method: continue feeding.

11. Discharging way: automatic continue discharge

FEATURES AT A GLANCE

3.Approximately 80 to 90% of the oil is recovered.

4.Low personnel costs due to continuous and automatic operation.

5.Highest g-force for higher solids output

6.Adjustable bowl speed via VFD

7.Automatic adjustment of differential speed via VFD

8.Two motor drive

9.Belts for both primary motor and secondary

10.NSK /SKF Bearing

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

•Abundant spare parts in stock are available to provide.

•Our technicians could be dispatched for overseas service.

•24 hours technical consultation.

•Routine tracing till the machine work properly will be done timely.

•We will remind you to do the normal maintenance.

•Your suggestions or any comments & reflection would be treated in priority.

•Your workers can get training easily by net video.

Customer Photos

FAQ

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian