Shenzhou - Horizontal Industrial Decanter Centrifuge Machine Palm Oil Sludge Separation

Produced by the latest technology, Horizontal Industrial Decanter Centrifuge Machine Palm Oil Sludge Separation Waste Mud Decanter Centrifuge presents its finest function well.The design of it has met varied needs of customers.It has been proved that can be applied to wide range because the product embodies superb characteristic than other products in the market.

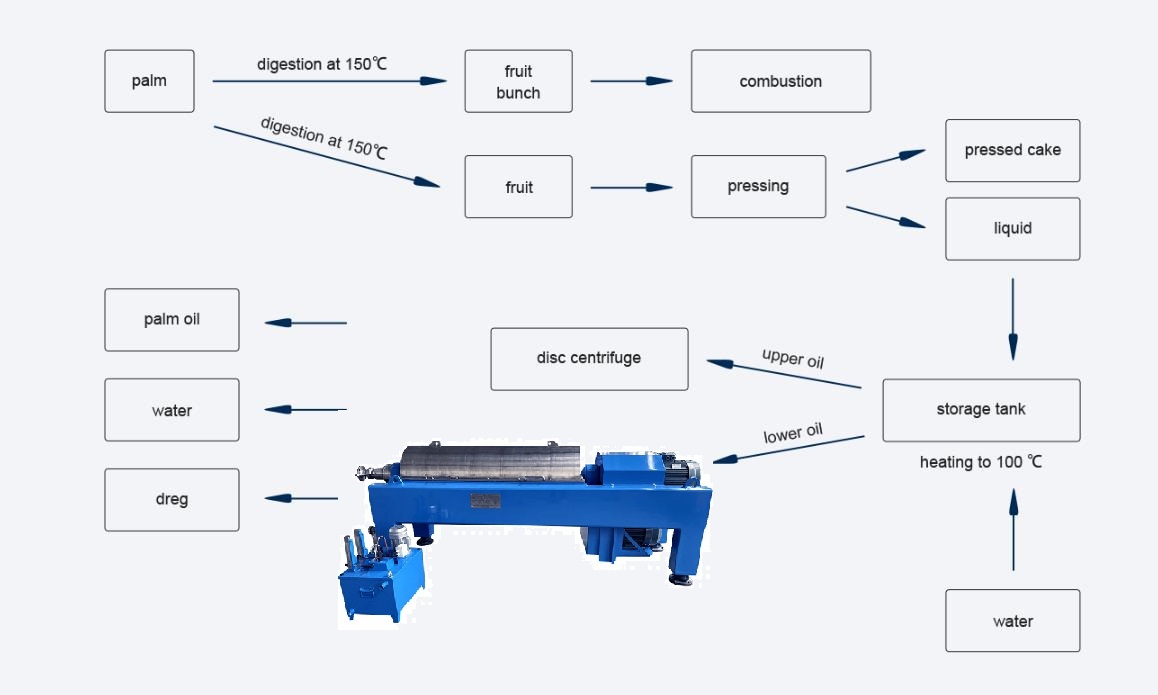

Palm Oil Extraction

Product Description

Palm oil is one of the most produced oils in the world. The global demand for palm oil is overgrowing. The traditional manual crushing method for extracting palm oil can no longer meet the palm oil market's needs. The three-phase decanter centrifuge provides an effective separation and purification program for palm oil processing plants' processing process. It can help palm oil mills process fresh palm fruit bunch (FFB) into crude palm oil (CPO), with the characteristics of high efficiency and high purity. Simultaneously, the equipment can work automatically and continuously for a long time, which can significantly improve the refining efficiency of palm oil. In the process of palm oil extraction, the palm oil decanter is used for: Direct processing of the crude oil after the screw press; Oil recovery from empty fruit bunch liquor; Crude oil recovery from the sludge in the CS tank; Crude oil recovery from the wastewater flow of the palm oil mill.

SEPARATION Decanters for Palm Oil Production Process

SHEENZHOU is a company that manufactures and develops different types of centrifuge equipment for all walks of life. For the palm oil separation and purification process, SZ has specially designed a food-grade palm oil three-phase centrifuge to realize the automatic separation and extraction of palm oil and the oil recovery from the sludge. In addition, SZseparation has a mature production technology that allows better results of separation which refers to less water consumption, less waste disposal, fewer costs, and more oil. SZcentrifuge adopts a frequency converter to control all operating parameters of the machine. Whether when running at a high speed or in the discharging process, it can significantly reduce the vibration and noise level during operation.

Oil palm processing process

Firstly, the fresh fruit bunches are sent to the preliminary pressing factory within 24h after harvesting (mainly to prevent the increase of FFA).

Then, the fruit bunches are heated to 150℃ and keep the temperature for 85min to sterilize the fruits and boil out the stalks.

The fruits then are separated from bunches by winder – peeling machine. After that, bunches can be used for combustion and fruits are introduced to silo.

Next, send the fruits into a screw press for high-pressure pressing. The pressed cake containing kernel (unbroken, containing palm kernel oil) is squeezed out from the machine head, and the liquid (mainly palm oil) is discharged from the liquid outlet of the presser.

The liquid is discharged from the outlet to a 100m³ tank, and be heated by water (maximum 100°C). After standing for a while the upper raw palm oil in the tank is directly discharged into the three-phase disc centrifuge to be separated; and the lower water containing palm oil would be separated in the 3 phase decanter (oil +water+ dreg).

Finally, the palm oil separated in the three-phase decanter is sent to a 100m³ tank again for standing and extraction of raw palm oil.

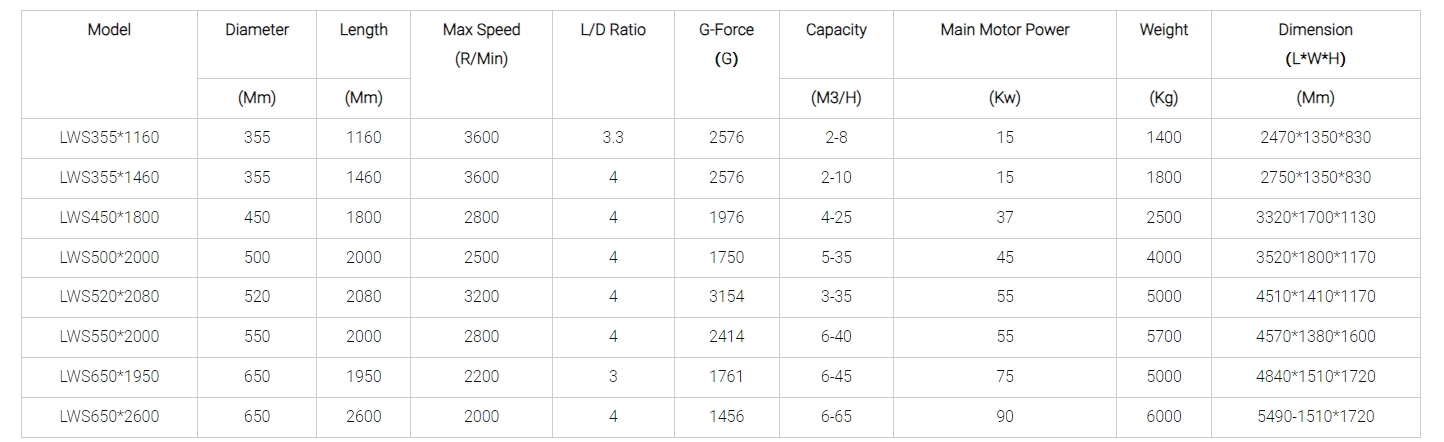

Product parameters from Shenzhou decanter

Our Customers

Shenzhou decanter pacakge: