After years of development, we have introduced and upgraded the technologies so as to make the manufacturing process more efficient.As more and more product advantages have been gradually discovered, LWS355 three phase olive oil separator china decanter centrifuge enjoys a wider range of application uses and now can be found in the field(s) of Separation Equipment.

Product Description

The 3-phase centrifuge is mainly composed of a driving part, a rotating cylinder, and a screw conveyor. lts operation is based on the principle of sedimentation. When the material enters a high-speed rotating drum, it rotates synchronously with the drum. Due to different specific gravity, the material is subjected todifferent centrifugal forces, with larger solid particles being subjected to centrifugal forces, followed bywater and the smallest amount of dirty oil. In this way, a concentric solid layer and two liquid layers are formed from the outside to the inside according to the magnitude of the centrifugal force. The solid ispushed out by the screw conveyor, and the liquid is discharged from the respective guide ports. lt is capableof solid-liquid separation.

This centrifuge can clarify, separate and dehydrate 0.002-3mm materials,or classify 1um-5um solid particles. lt has the characteristics of wide application range, continuous operation, large processing capacity, low cost, and convenient maintenance, making it the best equipment for solid-liquid separation. Widely used in industries such as chemical, light industry, medicine, food, papermaking, mining, etc.

BOWL ASSEMBLY FEATURES

Bowl Material: Duplex Stainless Steel SS2205/SS304

Solids Discharge Port: Corrosion-resistant steel and Tungsten Carbide insert

Bearing: SKF or Japan NSK Brand

Gearbox Type: Planetary wheel type

Screw Conveyor Material: Corrosion-resistant steel SS316L/SS304

Material Distribution Nozzle: : Tungsten Carbide insert

Screw Conveyor Wear Protection: Tungsten Carbide Tiles

Differential Speed: Adjustable according to conditions

Other Main Components

TECHINICAL CHARACTERISTICS

◆ High torque involute planetary gear differential.

◆ The entire machine is equipped with various safety overload protection devices.

◆ Ordinary type and explosion-proof type, depending on the situation.

◆ Large aspect ratio, high rotational speed, and multi angle rotating drum cone structure.

◆ The rack is designed as low center of gravity, high bracket, or mobile according to user needs.

◆ With BD plate spiral structure, it is suitable for the concentration and dehydration of activated sludge and materials that are difficult to separate.

◆ According to actual requirements, it can be matched with a dual frequency conversion and intelligent fully automatic control system.

FLEXIBLE FOR DIFFERENT LIQUID PHASE PROPOTION

An adjustable impeller discharges the "heavy" liquid phase. Furthermore, the operator can use the adjustable impeller to adjust the pond depth of the heavy liquid without difficulty during ongoing operation. According to the Proportion of two different phase, An adjustment mechanism causes the position of the impeller to change, thus changing the separation line of the liquids. The process engineering results can thus be influenced so as to achieve the required separation result.

Combined Driving Mode

Single Motor Drive: Single motor drive generally adopts a frequency conversion motor + frequency converter to drive the drum and screw at the same time.

The method is simple, the operation is simple, and the manufacturing cost is low. Single motor drive is mainly used for materials with constant solid content, and there is no strict requirement for the water content of the discharged solid phase. Because there is no necessary differential adjustment mechanism, the differential between the drum and the screw can only be realized by changing the gear transmission ratio or changing the drum speed.

Dual Motor Drive: Dual motor drive generally adopts two frequency conversion motors + two frequency converters tocontrol the dynamic rotation of drum and screw respectively.

ln the dual motor drive mode, the differential speed between the drum and the screw is adjusted by simply adjusting the speed of the motor. This driving mode is applied to materials with variable solid content and strict requirements for discharged solid water content.

Hydraulic Drive: The hydraulic drive generally adopts frequency conversion motor + frequency converter + hydraulic motor to drive the drum and screw respectively.

ln the hydraulic drive mode, the differential speed between the drum and the screw can be adjusted by the hydraulic motor. When moving at very low differential speed, its degree and stability are better than other driving methods.When the drum rotates normally, both the drum and the screw operate at a certain constant speed. Once the load of the screw pusher increases, the hydraulic motor will adjust the screw pusher to accelerate the operation to prevent material blockage.When the machine is stopped for cleaning due to material blockage, the hydraulic system can drive the screw pusher independently to improve the cleaning and maintenance efficiency.

Separation Range

A. When the liquid viscosity is small and the solid particle size is large, the specific gravity difference between solid, liquid and liquid is required to be ≥ 0.05g/cm3 (solid weight and liquid light).

B. When the liquid viscosity is small and the specific gravity difference between solid and liquid is large (specific gravity difference ≥ 1g / cm3), the solid particle is required to be ≥ 0.005mm and the specific gravity difference between liquid and liquid is required to be ≥ 0.05g/cm3.

C. When the liquid viscosity is large or the specific gravity of solid-liquid is small and the solid particles are very fine, the separation effect will be affected or even not applicable.

D. When the solid particles are easy to be damaged, the separation effect will also be affected.

Application For 3 Phase Decanter Centrifuge (Tricanter)

The Tricanters/ 3 phase decanters are used for the clarification and simultaneous separation of fluids of different densities; solid-liquid-liquid separation and two non-mixable liquids of different densities.

Areas Of Application For Tricanters (3 Phase Decanters)

Tricanters respectively 3 phase decanters (respectively separation decanters) are used for the clarification and simultaneous separation of fluids of different densities.

The tricanters / three phase decanters perform a 3 phase separation (solid-liquid-liquid separation) of dispersions of solid

material and two non-mixable liquids of different densities.

TYPICAL AREAS OF APPLICATION FOR TRICANTERS ARE THUS

* Treatment of sludges containing oil

* Separation of oil-water emulsions contaminated by solid materials

* Extraction of animal and plant oils and fat

* Furthermore * Fish press water from the fishmeal industry

* Manufacturing starch

* Olive oil

Functional And Constructional Characteristics Of Tricanters

Due to the high rotational speed of the drum solid material particles are deposited on the inner wall of the drum; at the same time the two liquids are separated from each other. The solid material particles spun off to the outside are continuously transported to the solid material discharge by the integrated screw conveyor.

The two liquid phases, separated from each other and almost completely free of solid material, overlay each other according to their density and leave the separation chamber by separate openings at the opposite end of the drum (cylindrical drum end). The two liquid phases can either be discharged freely (e.g. over a weir) or under pressure (by means of an integrated pump; peeling plate also called gripper).

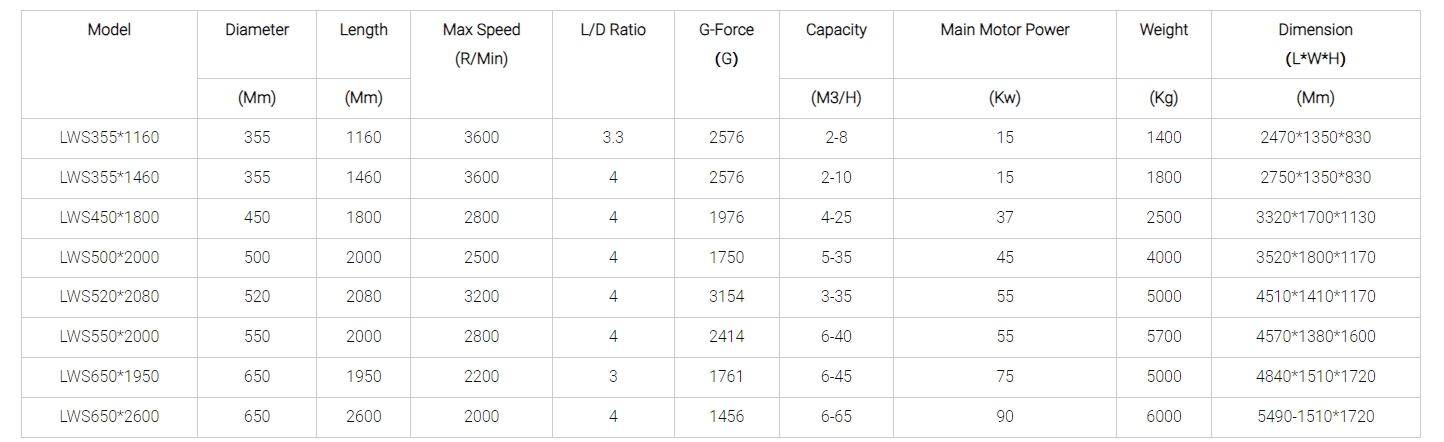

Technical Parameter

Other Main Components

Customers

Our factory

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1