Shenzhou - Factory supply animal manure processing organic fertilizer production line machinery Production Line equipment

Technology advancement ensures our leading position in the industry. We have been unswervingly updating and developing technologies. It is the utilization of high-end technologies that ensures the product properties are fully played out.Field(s) of Granulators have proved its superiority.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Applying the technology to the manufacturing process of the product turns out to be highly helpful. Featuring stability and durability, the product is suitable for the field(s) of Production Line equipment. The continued success of our product has been built upon consistent and competitive pricing, quality workmanship, quick response time and outstanding customer service. It is the support of our customers that propels us to continue to move forward. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd will keep providing high-quality products and professional services as always for customers. In addition, talents are the core pillar of a company. We will organize regular training on our staff to improve their skills.

| Place of Origin: | China | Condition: | New |

| Machine Type: | Granulator | Output (kg/h): | 200 |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product | Warranty of core components: | 1 Year |

| Core Components: | PLC, Motor, Gear | Brand Name: | LYSZ |

| Voltage: | 380 V | Dimension(L*W*H): | 100m*24m*8m |

| Weight (KG): | 3700 | Power (kW): | 55 |

| Warranty: | 1 Year | Key Selling Points: | Long Service Life |

| Applicable Industries: | Farms, Other | Showroom Location: | None |

| After-sales Service Provided: | Field installation, commissioning and training, Video technical support, Online support | After Warranty Service: | Online support, Field maintenance and repair service |

| Local Service Location: | None | Certification: | CE |

Product Description

Factory supply animal manure processing organic fertilizer production line machinery

Organic powder fertilizer granulation production line

The organic fertilizer production line project planned by our company for you is a high-tech project with significant economic and environmental benefits through the use of microbial fermentation and organic waste granulation to produce organic fertilizer.

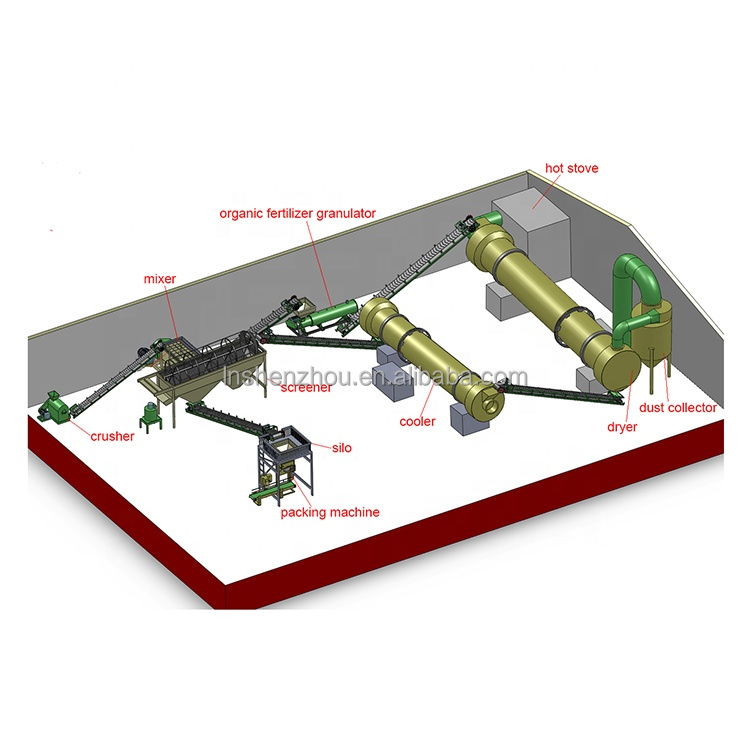

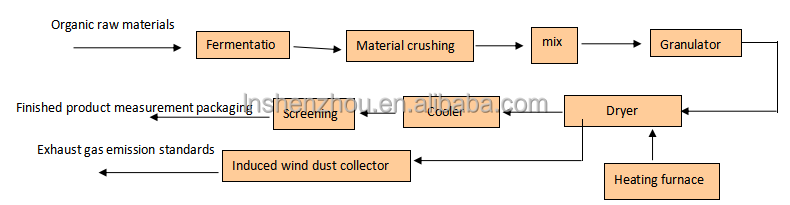

Process flow

1. Mainly organic waste materials (cow dung, sheep dung, pig dung, chicken dung, sludge, rice straw, corn stalks, mushroom residue) and other animal dung organic wastes are fermented and decomposed. The moisture content is about 30%-35%. After the waste is crushed and screened, it is measured with the binder (bentonite, humic acid) and other ingredients that need to be proportioned in the batching mixing system according to the proportioning requirements. (Adding functional bacteria can produce bio-organic fertilizer, adding nitrogen , Phosphorus and potassium (the total nutrient content is less than 15%) can produce organic and inorganic fertilizers) ingredients, mix, the fully mixed materials are uniformly and continuously fed into the granulator by the belt conveyor, and then rounded into a ball by the polishing and shaping machine The pellets are cooled and sieved after being dried by a dryer at low temperature and large air volume. The finished pellets are conveyed to the finished product silo by a belt, and are measured and packed into the warehouse by the computerized quantitative packaging system.

Specification

item | value |

Place of Origin | China |

Condition | New |

Machine Type | Granulator |

Output (kg/h) | 6 |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | Ordinary Product |

Warranty of core components | 1 Year |

Core Components | PLC, Motor, Gear |

Brand Name | LYSZ |

Voltage | 380 V |

Dimension(L*W*H) | 100m*24m*8m |

Weight (KG) | 3700 |

Certification | CE |

Power (kW) | 55 |

Warranty | 1 Year |

Field installation, commissioning and training, Video technical support, Online support | |

Key Selling Points | Long Service Life |

Applicable Industries | Farms, Other |

After Warranty Service | Online support, Field maintenance and repair service |

Local Service Location | None |

Showroom Location | None |

Organic powder fertilizer granulation production line

1.Strong adaptability. Suitable for the different formulations, different moisture content, and different concentrations of the

compound fertilizer and organic fertilizer.

2.Unique drying and cooling processing and handling. It can be sufficient to drying and cooling material, and again spheronization

and polishing on pellets.

3.Low temperature drying technology. It can produce the rich in active microbial ecological fertilizer.

4.Advanced technological processing design. The advantage of equipment layout is reasonable, compact structure, small spatial

footprint.

5.Using the rotary drum dryer by the main hosts of system. The advantage is strong adaptability, easy operation, and running

stability, and most reliability.

6.The hot air furnace could choose oil, gas, coal, biomass and other efficient automatic (or manual) hot air furnace as heat

source. The advantage is reasonable design, high thermal efficiency, and low drying cost.

7.Unique sealing device. It can be increasing the efficiency, without dust particles, and improve the operating environment

8.Suitable for the different desired customers that have different production capacity requirement. For example, the requirement

capacity of 1-20 million tons per year.

1.Strong adaptability. Suitable for the different formulations, different moisture content, and different concentrations of the

compound fertilizer and organic fertilizer.

2.Unique drying and cooling processing and handling. It can be sufficient to drying and cooling material, and again spheronization

and polishing on pellets.

3.Low temperature drying technology. It can produce the rich in active microbial ecological fertilizer.

4.Advanced technological processing design. The advantage of equipment layout is reasonable, compact structure, small spatial

footprint.

5.Using the rotary drum dryer by the main hosts of system. The advantage is strong adaptability, easy operation, and running

stability, and most reliability.

6.The hot air furnace could choose oil, gas, coal, biomass and other efficient automatic (or manual) hot air furnace as heat

source. The advantage is reasonable design, high thermal efficiency, and low drying cost.

7.Unique sealing device. It can be increasing the efficiency, without dust particles, and improve the operating environment

8.Suitable for the different desired customers that have different production capacity requirement. For example, the requirement

capacity of 1-20 million tons per year.

Details Images

Automatic batching machine

In various industrial production processes, a certain material or multiple materials are required to be quantitatively fed to ensure a stable production process or accurate material comparison. This is necessary for the smooth completion of the production process and the precise control of product quality. It has important meaning. The weighing feeder produced by Dalian Ruisi Machinery Co., Ltd. is specially designed to meet the needs of users in various industries. The automatic weighing feeder is accurate in weighing, reliable in operation, and can realize accurate quantitative feeding, which can help users reduce material waste, improve product quality and automate the production process.

grinder

The semi-wet material crusher is a new type of high-efficiency single-rotor reversible crusher. The high-speed rotating blade is used to pulverize fibers, with good pulverization particle size, high efficiency and high energy, and strong adaptability to the moisture content of the material, especially for the decomposed waste after fermentation or other materials with a moisture content of ≤30%. The powder granularity can reach 20-30 mesh, which can meet the feed granularity requirements of general fertilizer granulation equipment. Semi-wet material pulverizers are mostly used in the production and processing of organic fertilizers, and have good results in pulverizing raw materials such as chicken manure and sodium humate.

Blender

The horizontal mixer is a new generation of mixing equipment in our company. The mixing uniformity is high, the residual amount is small, and it is suitable for the mixing of compound feed, concentrated feed, and additive premix. The specific feature is: the materials are fully mixed. Thereby improving the mixing uniformity; adopting a novel rotor structure, the minimum gap between the rotor and the shell can be adjusted to near zero, effectively reducing the amount of residual material; the machine is equipped with grease adding pipes, the overall structure is more reasonable, and the appearance is beautiful. Convenient operation and maintenance.

Granulator

The rapid organic fertilizer granulator is also known as the wet stirring tooth granulator, the internal rotation stirring tooth granulator, this granulator is our company's latest research and development of a new type of organic fertilizer granulator. The wet organic fertilizer granulator is widely used for the granulation of organic fertilizer. Due to the high granulation rate, stable operation, sturdy and durable equipment, long service life, coupled with the stable base design, it makes the operation more stable, and it is selected as the ideal product by the majority of users. The specifications and models of the wet granulator are 600, 800, 1000 and other specifications, and can also be customized according to user requirements.

Round Throwing Machine

The machine is composed of two or more throwing cylinders arranged in sequence. After being rounded for many times, the material is discharged from the discharge port. The finished product has the same particle size, high density, smoothness, and high yield.

Dryer

The rotary dryer has a wide range of application, convenient operation and high operation rate. It is widely used in the cement industry to dry raw materials and fuels such as clay, slag, crushed stone, and coal. During drying, hot air or hot flue gas transfers heat to the material to evaporate moisture. At the same time, relying on the function of ventilation equipment, the drying medium in the drying equipment is constantly updated to remove water vapor. There are also various types of drying equipment. Commonly used in the cement industry are rotary dryers, fluid dryers, stirring (suspension) drying and active air drying tubes. In recent years, spray drying devices are still being studied at home and abroad. These equipments generally use hot flue gas for convection drying. The cylinder of the rotary dryer is generally a single straight cylinder. When installed, the cylinder is at an inclined angle with the horizontal. The material enters from the high end and flows slowly to the low as the cylinder rotates. Unload after the end. In small and medium-sized cement plants, the cylinder length of the dryer is generally 6-20m to ensure the residence time of the material in the dryer and meet the requirements of the drying process. The hot air from the hot blast stove and the materials exchange heat in the form of co-current or counter-current in the cylinder.

Cooler

The cooler speeds up the air flow inside the rotating cylinder through the suction of the induced draft fan (used with the equipment), and continuously lifts the material through the lifting plate installed on the rotating wall, so as to achieve the purpose of cooling. This machine is mainly used for the production of organic fertilizers, compound fertilizers and compound fertilizers. It cools granular fertilizers at a certain temperature. The rotary cooler is used in conjunction with the dryer, which can greatly increase the cooling speed, reduce labor intensity, increase output, and further remove part of the water. And reduce the grain temperature of the compound fertilizer. The rotary cooler can also be used to cool other powdery and granular materials. The equipment has a compact structure, high cooling efficiency, reliable performance and strong adaptability.

Packing & Delivery

wooden case

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

FAQ

1. who are we?

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap