In our company, we have been updating our technologies to manufacture the product.With those properties, Two-Stage Pusher Centrifuge for Salt-Dewatering has been functioning very well in the application field(s) of Separation Equipment.

Pusher centrifuge is a type of continuous filtration centrifuge that offers dewatering and washing materials continuously. it has been widely used for solids-liquid separation, such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances.

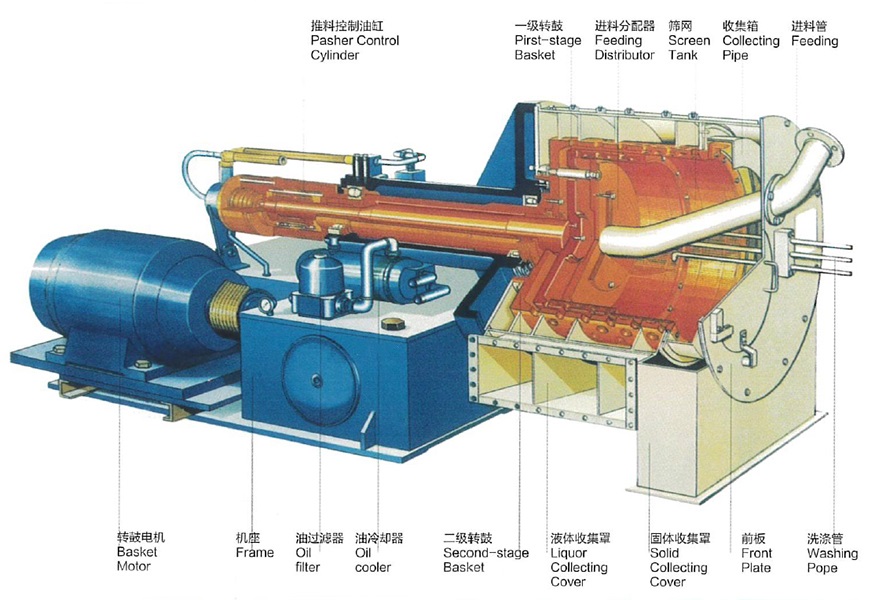

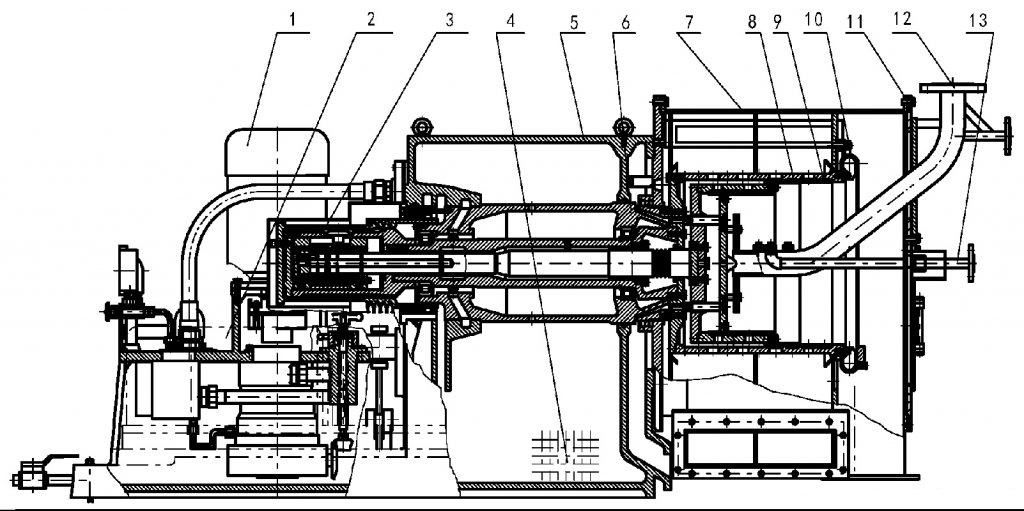

1 Oil pump 2 Motor 3 Pushing mechanism 4 Oil cooler 5 Frame 6 Bearing housing 7 Hood 8 Bowl 9 Screen 10 Collection chute 11 Door cover 12 Feed tube 13 Wash tube

Pusher centrifuge working principle

Two stage pusher centrifuge is continuously operating centrifuge. The product is fed through a feed pipe (or feed screw in the case of products that do not flow freely) into the feed distributor, which rotates with the basket. This accelerates the slurry and feeds it with uniform distribution to the feed zone, where the greater part of the liquid (approx. 80%) is filtered. In the feed zone, the solids grow to form a stable filter cake ring. The filter cake is conveyed in the direction of the solids discharge stroke by stroke due to the relative axial movement between pusher bottom and screen basket. During this process, an intact filter cake forms over the entire length of the screen. As the filter cake progresses from the feed zone to the solids discharge, it can be washed as required. For this purpose, a wash liquor is applied to the cake surface, displacing the suspension liquid and impurities. The solids are discharged at the end of the basket after each pusher movement.

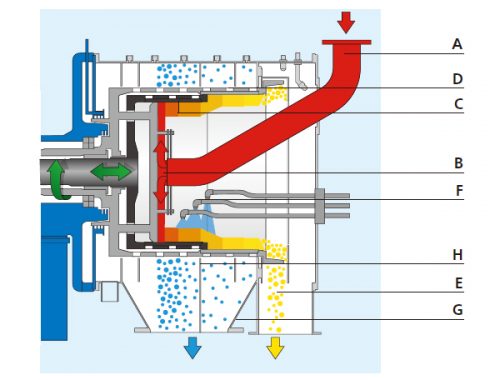

A. Suspension inlet

The pusher type centrifuge is continuously fed with the suspension to be separated (solid-liquid mixture) via the inlet pipe. In case of poorly flowing products, the feed is effected via an inlet screw conveyor .

B. Suspension distributor

The distributor accelerates and distributes the suspension over the entire periphery of the sieves in the filling area of the first basket stage. SHENZHOU offers various application-specific distribution systems for even and gentle acceleration and distribution of the suspension.

C. First basket stage

The greatest part of the liquid is already filtered out in the feed zone of the first basket stage, a stable cake forms. The first basket stage performs, along with a rotary movement, also an axial pusher movement (oscillation movement).

D. Second basket stage

The cake is pushed in annular sections by each pusher movement from the first to the second basket.

E. Solids discharge

After the second basket stage, the solids leave the pusher type centrifuge via the discharge track and the solids housing. Depending on the application, different discharge systems are used.

F. Product washing

If necessary, impurities in the mother liquor are washed out. The wash liquid is applied continuously over the cake via several adjustable wash nozzles.

G. Filtrate housing

The filtrate (filtered mother liquor and wash liquid) is collected in the filtrate housing and drawn off. Depending on the application, different filtrate housings and filtrate cyclones are used.

H. Filtrate separation

If necessary, the filtrate can be drawn off separately in each filtrate zone by means of separating plates fitted in the filtrate housing and disposed of or reused (e.g. counterflow washing).

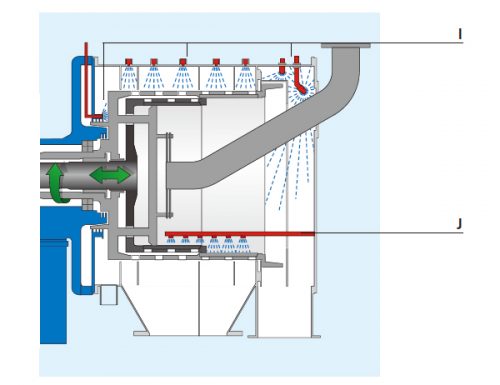

I./J. Flushing

The centrifuge process area is cleaned using flush liquid supplied through optimally arranged cleaning nozzles (I) and a clean pipe (J). Periodic flushing prevents the formation of crystals in the sieves and deposits in the solids housing.

Construction materials

Typical construction materials of pusher type centrifuge

• Austenitic steels • Duplex steels • Nickel-based alloys • Titanium

Applications of pusher type centrifuge

High degree of adaptability of two stage pusher type centrifuge enables it can be successfully used in a wide product range, examples are:

ABS polymerisate Adipic acid Ammonium chloride Ammonium hydrogen carbonate Ammonium molybdate

Ammonium sulphate Animal bone Calcium nitrate Calcium propionate Chloride hydrate

Copper sulphate Dicalcium phosphate Ferrous sulphate Fibrous materials Flotation concentrate from the potassium

Foodstuffs applications Glauber salt Granulate Hexamine Lithium hydroxide

Melamine Methacrylamide Milk sugar Nickel sulphate Monoammonium phosphate

Pentaeritritol Phosphate Potassium chloride Potassium nitrate Potassium sulphate

Potash Rape coarse grain Seed grains Silicone fluoride Soda

Sodium acetate Sodium chlorate Sodium chloride Sodium formiate Sodium carbonate Sodium nitrate

Sodium perborate Sodium sulphate anhydride Sorbic acid Soya coarse grain Tartaric acid Various mixed salts Zinc sulphate

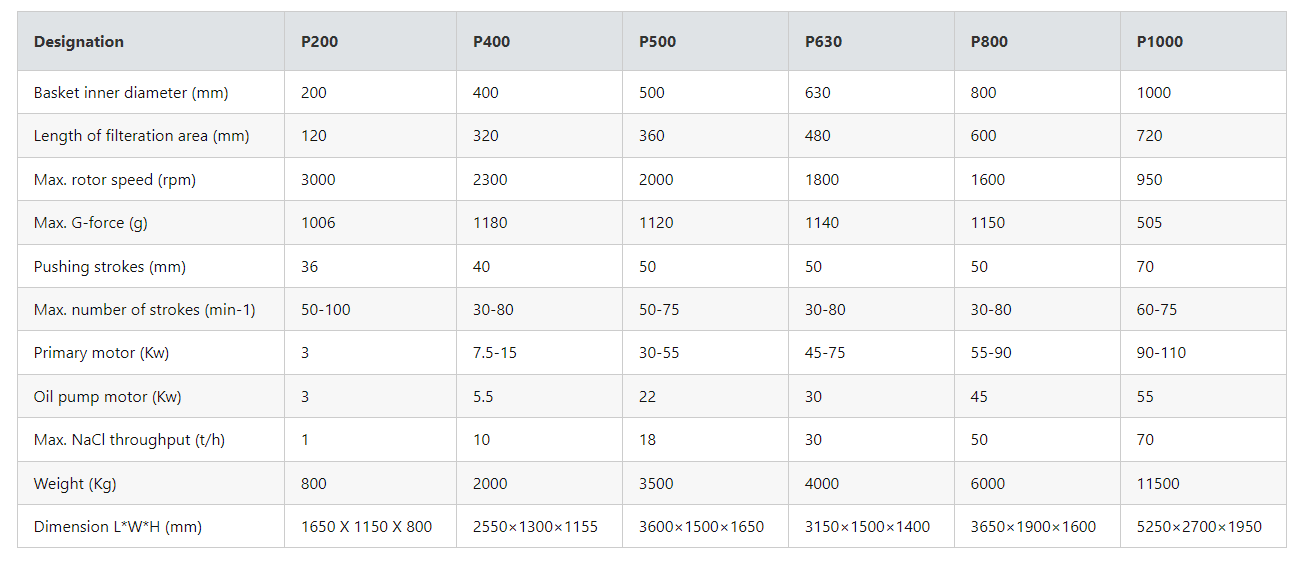

Technicial parameters

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1