Introduction Cell separation or harvesting is the first step towards downstream bioprocess and is required for the recovery of either extra- or intracellular products. A few different equipments can be found in industrial practices, and centrifuges are among the most commonly used in fermentation applications. Conventional centrifuges are a widely chosen option. In fact, being commonplace in laboratories, the relative ease of use and other advantages such as temperature control and variable speed make them a great choice, mainly for small-scale processes. The volume of the bucket is usually a limitation for this type of centrifuge [1]. For larger scales, continuous centrifuges have been the instrument of choice. The tubular-cylinder continuous centrifuges, in particular, are separation instruments characterized by their ability to process many times the capacity of their cylinder total volume without interruption. This characteristic results from a design that allows continuous feeding of a solid-liquid mixture while simultaneously expelling the liquid component. In a typical bioprocess application, the solid, which is retained in the cylinder, is the cell mass. Clarified liquid is obtained from an exit port while the machine is running. Cell mass is taken from the tubular cylinder after the machine is stopped. A removable plastic cylinder liner is often used to simplify cell paste removal.

Introduction to high speed tubular centrifuge

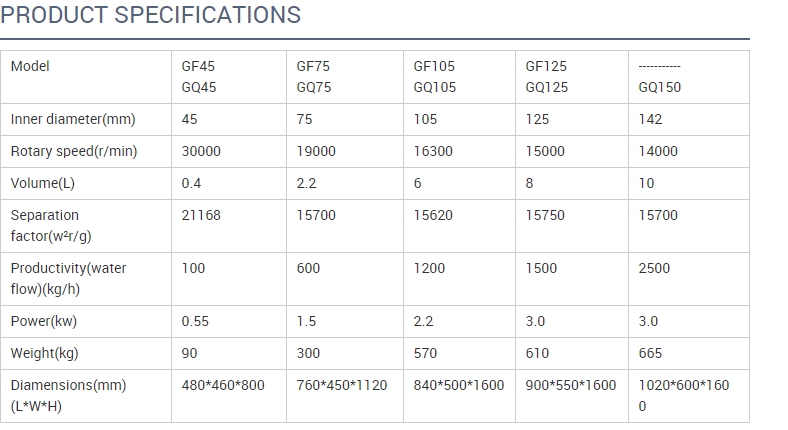

As an equipment manufacturer dedicated to providing users with separation solutions, Shenzhou recently released high-speed tubular centrifuge for the fine separation industry. Tubular centrifuge is a high-speed sedimentation centrifuge with a rotating bowl (also called rotor). Its bowl is of small diameter, long length, high speed and centrifugal separation factor of more than 10000. It can separate materials that are difficult to be separated by general centrifuges, such as suspension or emulsion with small solid concentration, fine particles (d separation = 0.5 ~ 1.0 μ m), large liquid viscosity and small solid-liquid density difference.

Different from horizontal decanter centrifuge and automatic slag discharge disc stack separator, tubular centrifuge belongs to manual slag removal equipment with limited treatment capacity, therefore it is suitable for working conditions with low solid content and relatively small treatment capacity. Tubular centrifuges are widely used in pharmaceutical, paint, fuel, biological products, beverage and other industries.

Classification of high speed tubular centrifuge

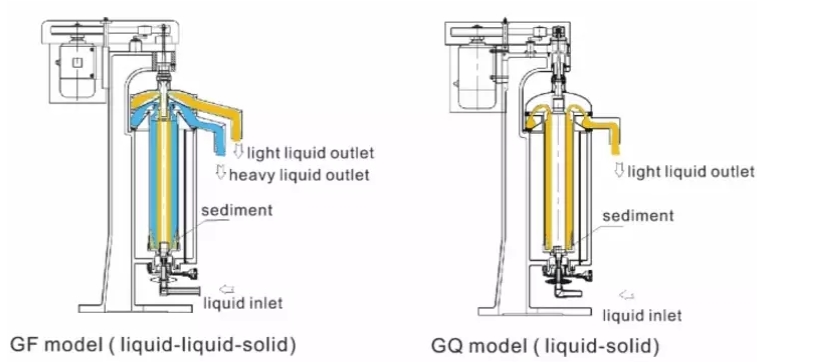

There are two types of tubular centrifuges (GF and GQ)

GF separation tubular centrifuge is used for liquid-liquid separation and emulsion separation with trace amount solid phase. The main function is to process the three-phase separation of liquid (light liquid), liquid (heavy liquid) and a small amount of solid, which is referred to as liquid-liquid-solid separation, or liquid-liquid separation. The common applications include vegetable oil, animal oil for oil-water separation and blood separation (pig blood, chicken blood, duck blood, cow blood and other animal blood).

GQ clarifying tubular centrifuge is used for the separation of suspension containing solid concentration less than or equal to 1%. Its main function is to process the separation of liquid and solid phases. The separated solid phase is deposited on the inner wall of the bowl and needs to be removed manually. Common applications include clarification and concentration in Chinese medicine water extraction or alcohol extraction, removal of large particle impurities from ink, separation of fermentation broth of biological products, such as various fermented low-density bacteria of vaccine, etc.

Working principle of high speed tubular centrifuge

The high-speed tubular centrifuge is fed from the bottom. After the slurry entering into the centrifuge, with the high-speed rotation of the bowl (the speed can be adjusted through the electric control cabinet), the substances with large specific gravity cling to the inner wall of the rotor/bowl, and the substances with light specific gravity are in the middle part of the rotor. The liquid gradually rises spirally from bottom to top and flows out from the upper outlet of the rotor. The upper part of the tubular centrifuge will have liquid outlets for light liquid phase and heavy liquid phase respectively. When the material contains solid phase, the solid will be accumulated inside the rotor. After the accumulation is full, operator need to shut down and disassemble the rotor, clean the inside of the rotor, install the rotor again, and then enters into the next separation process.

Features of shenzhou high speed tubular centrifuge

1. The enclosure is of cast structure, and then heating treated to eliminate stress. The inner and outer surfaces are lined with stainless steel 304.

2. The rotor, feed pipe, liquid collecting tray and other parts in contact with slurry are made of stainless steel 316L.

3. The lower end cover of the rotor is sealed with Teflon sealing ring, which fully meets the GMP requirements.

4. The surface treatment of the centrifuge meets the GMP requirements of the pharmaceutical industry, the body is smooth without convex and concave, and the corner part is circular arc transition;

5. It can be equipped with VFD control panel to reduce the motor starting current, reduce the damage of transmission parts and wearing parts, and improve the service life of equipment and motor.

6. The enclosure of some models is designed as open door or swing type, which is convenient for disassembly and assembly of the rotor when slag removal, which reduces labor intensity and improves production efficiency, and it does not affect the separation effect of the centrifuge.

For more information about high-speed tubular centrifuges, please contact shenzhou Separation. Shenzhou Separation is a professional manufacturer of separation equipment. Centrifuge product series include horizontal decanter centrifuge, disc separator and high-speed tubular centrifuge; the product series applied to sludge dewatering include sludge dewatering centrifuge, screw press and polymer dosing unit. In addition Shenzhou Solids specializes in providing drilling mud recycling and oilfield waste treatment solutions. If any requirements aroused, please contact Shenzhou company.

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1