Thickened sludge decanter is a device which is able to directly dehydrate the excess sludge of low concentration generated in the sewage and wastewater treatment plant without separating sludge thickener. It is a high-tech device available of drastically decreasing the expense for the excess sludge facility and device.

*Advance treatment of wastewater treatment plant. Direct dehydration of excess sludge

*Improved performance (percentage of moisture content) of the existing screw decanter

*Dehydration of waste liquid from the food treatment plant

*Direct dehydration of various low concentration sludge

Structure and Principle – Screw Decanter(Thickener+Dehydrator)

*Adds cohesive agent to inflow sludge of low concentration in the thickener and condenses the solid to make it flock

*The flocked sludge is condensed on a proper concentration suitable for screw decanting. The condensed sludge is supplied to screw decanter by the feeder attached to the side

*Overall dehydration performance is enhanced since the sludge inflow into screw decanter in condensed state and skipping the condensation action is possible

Feature – Screw Decanter(Thickener+Dehydrator)

1.Largely improved process through making binary condensation and dehydration process into single process

*One-step condensation and dehydration process leads to largely improved process

*Expenses for installing the facilities such as civil engineering structure, transfer pump, and pipe are reduced since there is no sludge thickening impound process

*Minimized installation space since the space for mechanical thickener is not needed due to the single process

*Convenient maintenance and improved efficiency with single process

*Minimized power consumed for sludge processing process

*Innovative process improvement

2. Energy cost reduction

*Power consumption is largely decreased since condensation device needs little power and the decanter capacity is under 50%.

3. Enhanced dehydration efficiency of screw decanter

*The percentage of moisture content in dehydration cake is improved by 2~5 % compared to other type of thickened sludge. Since it inflows to decanter in solid flock state during the submerged condensation process, the efficiency of solid-liquid separation by centrifugal force is enhanced leading to higher decanter efficiency

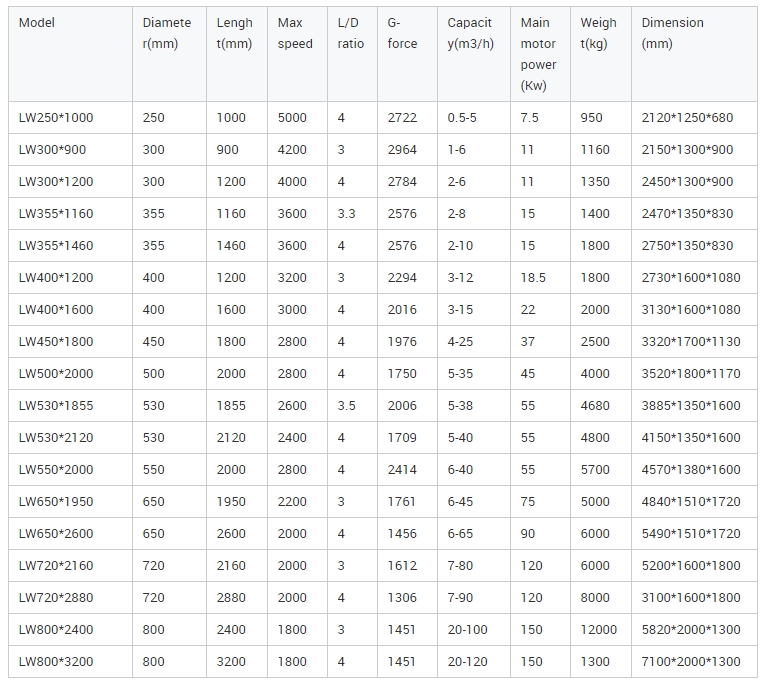

Technical Parameter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1