Professional Thickened sludge decanter manufacturers

Thickened sludge decanter is a device which is able to directly dehydrate the excess sludge of low concentration generated in the sewage and wastewater treatment plant without separating sludge thickener. It is a high-tech device available of drastically decreasing the expense for the excess sludge facility and device.

*Advance treatment of wastewater treatment plant. Direct dehydration of excess sludge

*Improved performance (percentage of moisture content) of the existing screw decanter

*Dehydration of waste liquid from the food treatment plant

*Direct dehydration of various low concentration sludge

Structure and Principle – Screw Decanter(Thickener+Dehydrator)

*Adds cohesive agent to inflow sludge of low concentration in the thickener and condenses the solid to make it flock

*The flocked sludge is condensed on a proper concentration suitable for screw decanting. The condensed sludge is supplied to screw decanter by the feeder attached to the side

*Overall dehydration performance is enhanced since the sludge inflow into screw decanter in condensed state and skipping the condensation action is possible

Feature – Screw Decanter(Thickener+Dehydrator)

1.Largely improved process through making binary condensation and dehydration process into single process

*One-step condensation and dehydration process leads to largely improved process

*Expenses for installing the facilities such as civil engineering structure, transfer pump, and pipe are reduced since there is no sludge thickening impound process

*Minimized installation space since the space for mechanical thickener is not needed due to the single process

*Convenient maintenance and improved efficiency with single process

*Minimized power consumed for sludge processing process

*Innovative process improvement

2. Energy cost reduction

*Power consumption is largely decreased since condensation device needs little power and the decanter capacity is under 50%.

3. Enhanced dehydration efficiency of screw decanter

*The percentage of moisture content in dehydration cake is improved by 2~5 % compared to other type of thickened sludge. Since it inflows to decanter in solid flock state during the submerged condensation process, the efficiency of solid-liquid separation by centrifugal force is enhanced leading to higher decanter efficiency

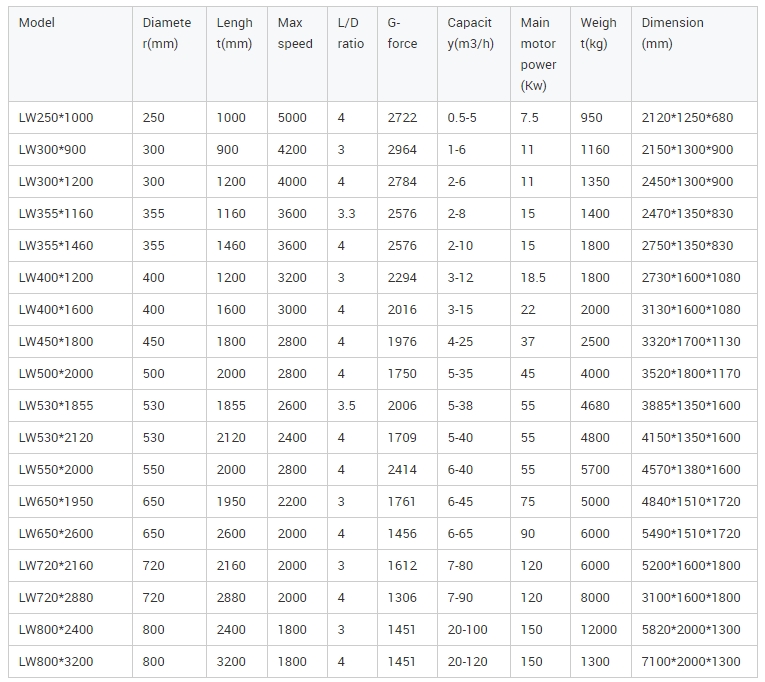

Technical Parameter: