centrifuge 12000rpm

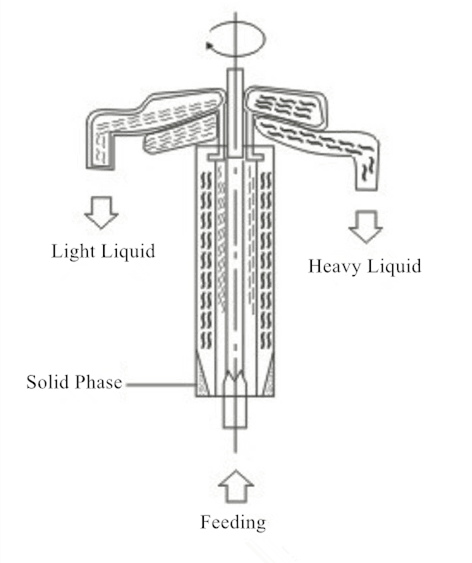

The tubular centrifuge is used primarily for the continuous separation of liquids from liquids or of very fine particles from liquids, although in some cases it is employed as a batch-type centrifuge. In general, it is used when higher centrifugal fields are required for separation. The rotating bowl of a tubular centrifuge consists of a long hollow tube (length many times its diameter) as shown schematically in above picture. For continuous separation the feed or material to be centrifuged enters at one end near the axis and is removed in two streams containing the separated material.

Many different designs for the internal structure of the tube are employed, but, in general, radial vanes are used to bring the feed material up to speed and to slow down the separated streams before they are discharged. The centrifuge is driven by a high-speed motor. The sedimentation takes place as the fluid flows from one end of the tube to the other. When the heavy material consists of very fine particles or molecules and the concentration is very low, the solid material is usually allowed to deposit on the wall. In this case the machine is operated as a batch centrifuge.

The tubular centrifuge is finding an increasing number of applications because of the high centrifugal fields that may be used (15,000g near the periphery in some cases). A few typical uses are as follows:

━ the purification of vaccines (uncentrifuged vaccines contain a large amount of nonessential and harmful material),

━ purification of lubricating and industrial oils,

━ clarification and purification of food products such as essential oils, extracts, and fruit juices, and

━ separation of immiscible liquids that cannot be separated by gravity.

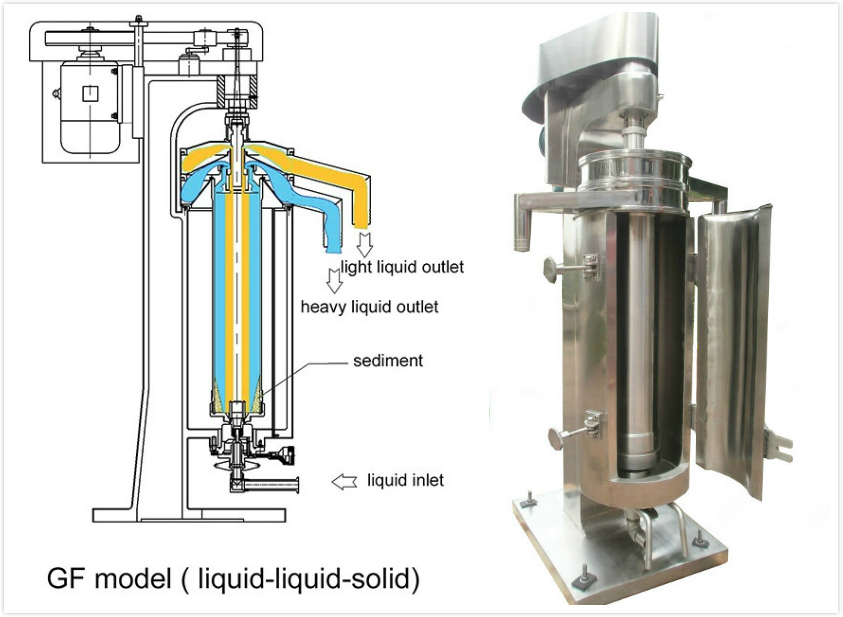

GF TUBULAR CENTRIFUGE

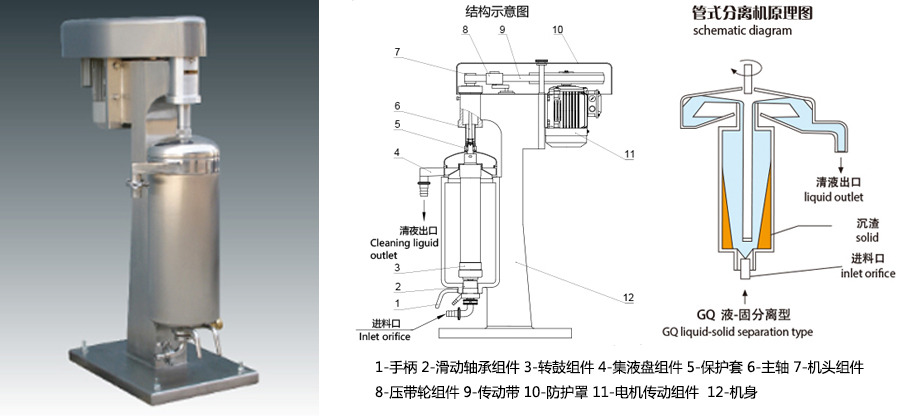

GQ TUBULAR CENTRIFUGE

High speed separation & clarification. GF series Tubular Centrifuge from Huading Separator is a high speed solid bowl type machine for continuous separation of two immiscible liquids with density difference. This centrifuge is also used to separate small quantity of impurities from liquids.

The tubular centrifuge is consisted of frame body, driving device, bowl and motor.

GF tubular centrifuge is designed to separate two (2) immiscible liquids of differing densities. The high centrifugal force generated causes the high density liquid to migrate toward the tube wall while the lower density liquid is displaced to the center of the tube. The separated liquids are then discharged at the top of the tube with dedicated outlets.

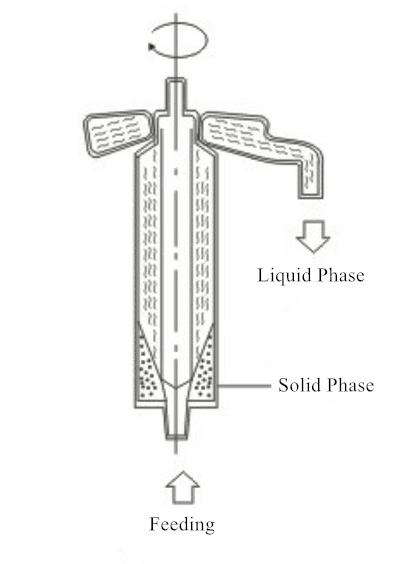

GQ TUBULAR CENTRIFUGE:

High speed separation & clarification. GQ series Tubular Centrifuge from Huading Separator is a high speed solid bowl type machine for continuous removing solids from liquid with density difference.

GQ tubular centrifuge is designed to separate low percentages of solids between 1 and 0.001 microns in size which are suspended in a liquid. The high centrifugal force generated causes the solids to migrate to the wall of the centrifuge tube where they are retained. The clarified liquid is the discharged at the top of the tube.

Tubular centrifuge is an ideal instrument in biology, traditional medicine preparation, health food, chemistry for liquid-solids separation. It is especially designed for separation and clarification of process liquid with low density difference, small granularity, low solid content, strong medium corrosion.

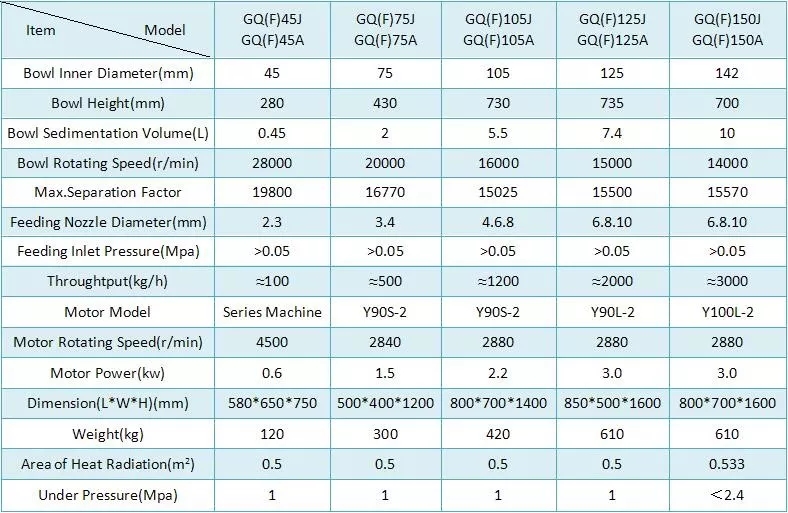

Technial Parameter:

Rotational Speeds that Provide Excellent Separation

The rotational speed of a centrifuge is directly related to the separation effect and output of the centrifuge, and the same is true for tubular centrifuges. Under the same conditions, the higher the rotational speed is, the better the separation effect and the greater the output. Our GQ105 tubular centrifuge factory speed 18400r/min (up to 19000r/min, ±100), other manufacturers of the same type of machine is 16000-16300r/min, our company this type of tubular centrifuge can be separated from liquid materials in more than 30 nanometers of particles, other manufacturers of the same type of machine can be separated from more than 300 nanometers of particles. The output is more than 25% higher.

More Superior 2205 Duplex Steel Material

The drum of traditional tubular centrifuge is made of 304 stainless steel, or 316L stainless steel, which is better. The tubular centrifuge uses 2205 duplex steel, the mechanical properties and corrosion resistance of this material are better than 304 or 316L, the drum is not easy to deformation, so that the operation of the equipment is more stable, reducing the cost of using equipment.

Optimized to Provide Better Stability

The tubular centrifuge produced by our company has optimized the structure of the traditional high-speed transmission part, the structure of the inlet bearing seat part and the heat treatment process of the bowl, in addition to the reasonable optimization of the material of certain wearable parts.

Upgraded High-speed Transmission Part

The traditional high-speed transmission part has a complex structure, many parts, and many wearing parts. Many parts lead to a large cumulative tolerance of the assembly, resulting in large vibration, noise, unstable operation when the equipment is working, affecting the service life. Many wearing parts lead to the increase of the cost of using the equipment. Our high-speed transmission part simplifies the traditional structure, which increases the processing difficulty but reduces the cumulative tolerance of assembly, makes the equipment operate with low vibration, low noise, smooth operation, increases the service life and reduces the cost of use.

New Inlet Bearing Seat Dampens All Points

The design structure of the inlet bearing seat part is a damping structure, and the traditional structure can not play a damping role at all points on the circumference, which increases the instability and failure rate of the equipment operation. After our company changed the structure of the inlet bearing seat, not only can all points on the circumference play a damping role, but also make the original single damping structure into a double damping structure, which enhances the stability of equipment operation, prolongs the service life of wearing parts, and reduces the failure rate.

3 Times Bowl Heat Treatment Process

Traditional bowls are only heat treated once, either to increase bowl strength or to increase corrosion resistance (only increasing corrosion resistance treatment does not meet the requirements of industry manufacturing standards), which can only have a single effect. Our bowls are heat-treated three times to increase bowl strength, increase corrosion resistance and stress failure. The change in material of certain wearing parts extends the service life of the wearing parts, thus reducing the cost of use for users.

Special tools for the machine .

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1