Best China tubular centrifuge manufacturer,high quality tubular centrifuge,tubular centrifuge is used to separate solids from a liquid (also referred to as clarifying cylinder), tubular centrifuge which continuously separates two liquids.The tubular centrifuge comprises of bowl, specially designed slow acceleration motor and starter.

The tubular centrifuge is used primarily for the continuous separation of liquids from liquids or of very fine particles from liquids, although in some cases it is employed as a batch-type centrifuge. In general, it is used when higher centrifugal fields are required for separation. The rotating bowl of a tubular centrifuge consists of a long hollow tube (length many times its diameter) as shown schematically.

For continuous separation the feed or material to be centrifuged enters at one end near the axis and is removed in two streams containing the separated material. In many cases the separation is not complete, and the separated fractions must be passed through the tubular centrifuge several times. Many different designs for the internal structure of the tube are employed, but, in general, radial vanes are used to bring the feed material up to speed and to slow down the separated streams before they are discharged. The tubular centrifuge is driven by a high-speed motor or an air or steam turbine. The sedimentation takes place as the fluid flows from one end of the tube to the other. When the heavy material consists of very fine particles or molecules and the concentration is very low, the solid material is usually allowed to deposit on the wall. In this case the tubular centrifuge is operated as a batch centrifuge.

The tubular centrifuge is finding an increasing number of applications because of the high centrifugal fields that may be used (105g near the periphery in some cases).

A few typical uses are as follows: (1) the purification of vaccines (uncentrifuged vaccines contain a large amount of nonessential and harmful material), (2) purification of lubricating and industrial oils, (3) clarification and purification of food products such as essential oils, extracts, and fruit juices, and (4) separation of immiscible liquids that cannot be separated by gravity.

Tubular centrifuges are used for the recovery or the elimination of liquid suspended impurities, and for the separation of two (2) non-miscible liquids of different densities. The GQ and GF are available either as a clarifying type or separating type of tubular centrifuge.

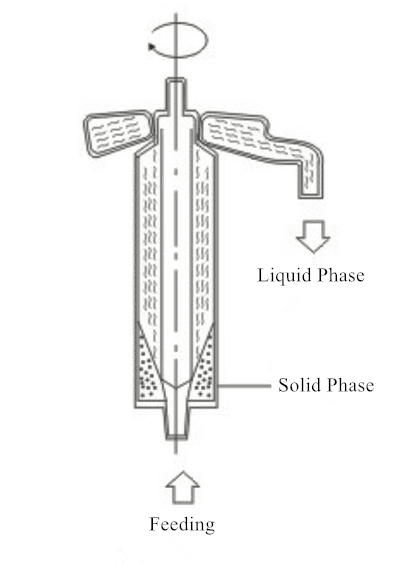

Clarifying type tubular centrifuge(Solid-Liquid Separation)

The GQ as a clarifying type of tubular centrifuge is designed to separate low percentages of solids bigger than 0.001 microns in size which are suspended in a liquid. The high centrifugal force generated causes the solids to migrate to the wall of the centrifuge tube where they are retained. The clarified liquid is the discharged at the top of the tube.

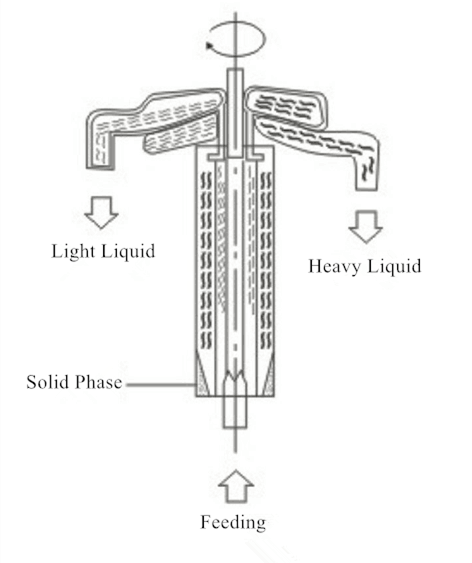

The GF as a separating type of tubular centrifuge is designed to separate two (2) immiscible liquids of differing densities. The high centrifugal force generated causes the high density liquid to migrate toward the tube wall while the lower density liquid is displaced to the center of the tube. The separated liquids are then discharged at the top of the tube with dedicated outlets.

Separating tubular centrifuge type (Liquid-Liquid-Solid Separation)

The GF as a separating type of tubular centrifuge to separate three (3) phase solutions. If any solids are present they will collect on the wall of the centrifuge tube while the two (2) separated liquids are discharged at the top of the tube by the dedicated outlets.

Tubular Centrifuge comprises of bowl, specially designed slow acceleration motor & starter. The bowl rotates at 15000 r.p.m. generating a centrifugal force of 16000 times the gravitational force. The liquid mixture to be separated enters the nozzle of the Centrifuge placed at the bottom base. The Centrifugal force acts on the liquid entering to their specific gravities. The lighter liquid forms the inside layer and heavier liquid forms the outside (Toward wall to bowl) layer. Since the Mixture is entering continuously in the bowl, two phases are discharged continuously from two separate holes provided on the top portion of the bowl. During clarification job, one discharge hole of the bowl is closed and continuous discharged on clarified liquid is possible.

Continuous tubular centrifuge

•Tubular centrifuge for continuous treatment

•Two phase (liquid/solid) separation

•High recovery of sludge (cake type)

•Water jacketed cooling system (optional)

•Up to two pumps

•Easy loading and unloading with safety 4 door-racks

•Intuitive touch-screen control panel

•Robust design and shock proof operation

Applications of tubular centrifuge

Pharmaceutical areas

Collection of pharmaceutical intermediates, herb extracts, plant fibers and chlorella

Food processing areas

Soy bean, fat, vegetable oil, starches, grains, gelatin, amino acids, soy sauce, reducing fat in milk

Waste water treatment

Cleaning on straining waste water, leather waste water, petroleum tank sludge, waste oil

Chemistry industry areas

Cleaning and collection of ink, paints, ammonia, barium, aluminum, zinc, activated charcoal and stainings

The other fields

Milk fat processing, cosmetics, cod-liver oil, yeast processing, and many other separation of solution and collection of solids

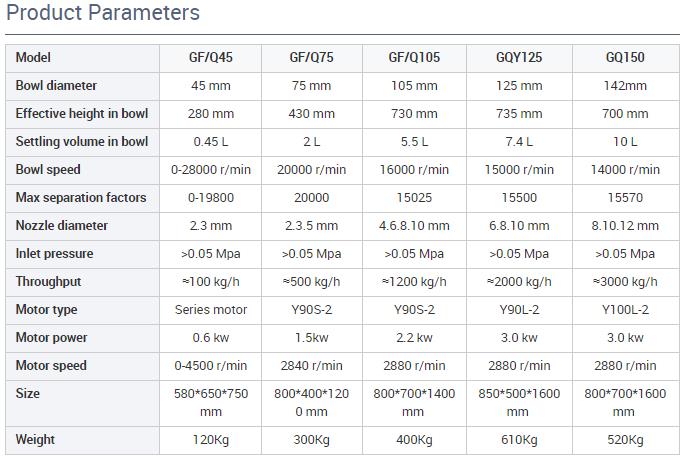

Technical Paramter:

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1