Introduction

With the increasing demand for healthy beverages among consumers, the fruit juice beverage market continues to grow. As a highly efficient solid-liquid separation device, the decanter centrifuge plays an important role in the production of fruit juice beverages. This article will discuss the application of the decanter centrifuge in fruit juice beverages from aspects such as working principle, advantages, and specific applications.

|  |

With the increasing demand for healthy beverages among consumers, the fruit juice beverage market continues to grow. As a highly efficient solid-liquid separation device, the decanter centrifuge plays an important role in the production of fruit juice beverages. This article will discuss the application of the decanter centrifuge in fruit juice beverages from aspects such as working principle, advantages, and specific applications.

|  |

The decanter centrifuge separates the solid particles (such as pulp and pomace) from the liquid in the fruit juice by the centrifugal force generated by high-speed rotation. Its core components include:

Drum: A high-speed rotating cylinder that is responsible for generating centrifugal force.

Screw Conveyor: Discharges the separated solid particles from the drum.

Differential: Adjusts the speed difference between the screw conveyor and the drum to ensure the separation effect.

Working Process:

The fruit juice enters the drum through the feed pipe.

Under the action of centrifugal force, the solid particles are deposited on the inner wall of the drum, and the liquid is discharged through the overflow port.

The screw conveyor pushes the solid particles towards the slag discharge port, realizing the separation of solid and liquid.

Efficient Separation

The decanter centrifuge can quickly separate the solid and liquid in the fruit juice, has a large processing capacity, and is suitable for large-scale production.

High Degree of Automation

The equipment is equipped with an automatic control system, which is easy to operate and reduces manual intervention.

Strong Adaptability

It can handle different types and concentrations of fruit juices and is suitable for the separation of juices from various fruits.

Energy Conservation and Environmental Protection

By recovering the solid particles (such as pomace) in the fruit juice, it reduces the discharge of waste and realizes the recycling of resources.

Small Floor Space

Compared with traditional filtration equipment, the decanter centrifuge has a compact structure and saves space.

Pulp Separation

Used to separate the pulp in the fruit juice and improve the clarity of the fruit juice.

Suitable for the production of fruit juices containing pulp such as orange juice and apple juice.

Pomace Dewatering

Used to dewater the pomace generated in the fruit juice production process, reducing the volume of the pomace for easy transportation and disposal.

The dewatered pomace can be used as feed or organic fertilizer.

Fruit Juice Clarification

Used to separate the tiny solid particles in the fruit juice, improving the transparency and taste of the fruit juice.

Suitable for the production of fruit juices requiring high clarity such as grape juice and pear juice.

Pectin Separation

Used to separate the pectin in the fruit juice, improving the purity and stability of the fruit juice.

Suitable for the production of citrus fruit juices.

Selection Key Points

Select the appropriate model according to the type of fruit juice, solid concentration, and processing requirements.

Consider the material of the equipment (such as stainless steel) to deal with acidic fruit juices.

Maintenance Suggestions

Regularly check the wear condition of the drum and the screw conveyor.

Clean the inside of the equipment to prevent blockage.

Lubricate the key components to ensure the normal operation of the equipment.

Intelligentization

Realize remote monitoring and fault diagnosis through the Internet of Things technology to improve the operation efficiency of the equipment.

Energy Conservation

Optimize the equipment design, reduce energy consumption, and cut down the operation cost.

Multifunctionality

Develop universal equipment suitable for various fruit juice separation scenarios to enhance market competitiveness.

With its characteristics of high efficiency, energy conservation, and environmental protection, the decanter centrifuge has become an indispensable equipment in the production of fruit juice beverages. With the continuous progress of technology, the decanter centrifuge will play a greater role in the future production of fruit juice beverages, providing strong support for the high-quality development of the industry.

If you need more detailed technical parameters or case analysis, please let me know!

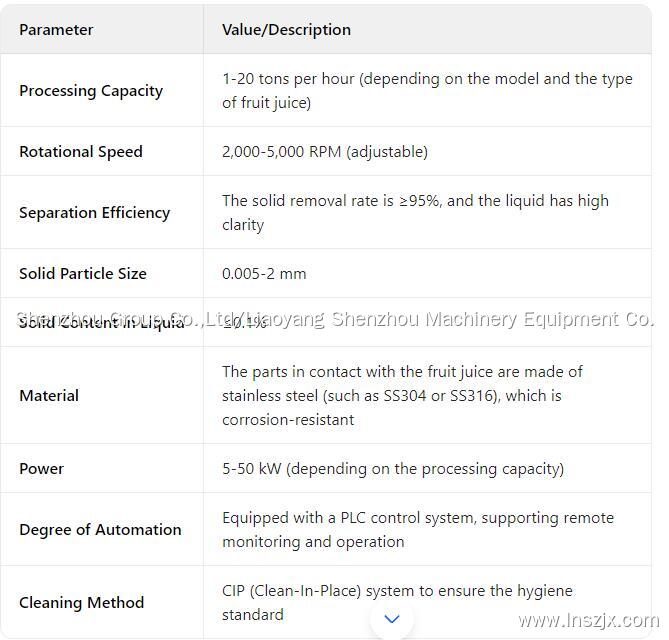

The following are the typical technical parameters of the decanter centrifuge in fruit juice separation:

Customer Requirement: A fruit juice production enterprise needs to separate the pulp from orange juice to improve the clarity and taste of the juice.

Solution: A decanter centrifuge is adopted, with the rotational speed set at 3,500 RPM and the processing capacity at 10 tons per hour.

Effect:

The pulp separation efficiency reaches 98%, and the clarity of the orange juice is significantly improved.

The water content of the pomace is reduced to 75%, making it easier for subsequent processing.

The equipment operates stably, and the high degree of automation reduces manual operation.

Case 2: Apple Juice Clarification

Customer Requirement: A beverage company needs to remove the tiny solid particles in apple juice to improve the transparency of the product and its market competitiveness.

Solution: A decanter centrifuge is used, with the rotational speed set at 4,000 RPM and the processing capacity at 8 tons per hour.

Effect:

The removal rate of solid particles in the apple juice reaches 96%, and the transparency of the product is significantly enhanced.

The energy consumption during the operation of the equipment is low, meeting the environmental protection requirements.

Rapid cleaning is achieved through the CIP system, ensuring production hygiene.

Case 3: Pectin Separation in Grape Juice

Customer Requirement: A winery needs to separate pectin from grape juice to improve the purity and stability of the juice.

Solution: A decanter centrifuge is adopted, with the rotational speed set at 3,800 RPM and the processing capacity at 5 tons per hour.

Effect:

The pectin separation efficiency reaches 95%, and the purity of the grape juice is significantly improved.

The separated pectin can be used for other food processing, realizing the recycling of resources.

The noise during the operation of the equipment is low, meeting the environmental requirements of the factory.

III. Technical Advantages

Efficient Separation: It can quickly separate the solid and liquid in the fruit juice, improving production efficiency.

Strong Adaptability: It is suitable for the separation needs of various fruit juices (such as orange juice, apple juice, grape juice, etc.).

Automated Operation: Reduces manual intervention and lowers the operation difficulty and cost.

Energy Conservation and Environmental Protection: With a low-energy consumption design, it meets the environmental protection requirements of modern industry.

High Hygiene Standard: The CIP cleaning system is adopted to ensure that the equipment meets the hygiene standards for food production.

IV. Future Development Trends

Intelligentization: Realize remote monitoring and fault diagnosis through the Internet of Things technology to improve the operation efficiency of the equipment.

Multifunctionality: Develop universal equipment suitable for various fruit juice separation scenarios to enhance market competitiveness.

Energy Conservation: Optimize the equipment design to further reduce energy consumption and cut down the operation cost.

If you need more detailed technical parameters or customized solutions, please let me know!

|  |

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

Copyright © 2025 Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd - www.lnszjx.com All Rights Reserved.辽ICP备18010813号-1