Shenzhou Decanter Centrifuge for Wastewater Treatment

The main purpose of wastewater sludge treatment is to remove as much suspended matter as possible and achieve solid-liquid separation before the discharge of wastewater and sludge. This purifies the wastewater and concentrates the sludge, thus realizing the recycling of water resources.

Shenzhou wastewater treatment centrifuges can be used in urban domestic sewage treatment, chemical sewage purification, sludge thickening and other related sewage and sludge treatment industries. Modern wastewater treatment processes and discharge standards are becoming more and more stringent, and the subsequent treatment of dewatered sludge cake is more difficult, whether it is stacked, dried or incinerated, placing higher demands on the key equipment for residual sludge treatment. Shenzhou SEPARATION can provide professional technical support and customized services for your specific needs.

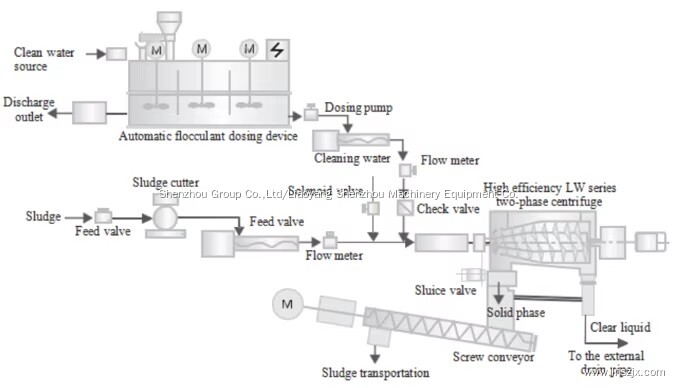

Wastewater Treatment Process

Cut and crush the biochemical sludge.

Pump the sludge (concentration ≥0.5~4%) into the centrifuge.

Add (concentration 1~3‰) PAM solution into the feed pipe through the automatic dosing device to make the sludge form flocs into the centrifuge.

The dewatered sludge cake is discharged from the bowl.

The dewatering system is widely used in oxidation ditch, AB, A/O, A3/0, SBR, MBR, anaerobic fermentation and other processes as well as traditional wastewater treatment processes, and can treat urban domestic sewage, municipal sewage, garbage leachate, municipal tap water and some industrial wastewater.

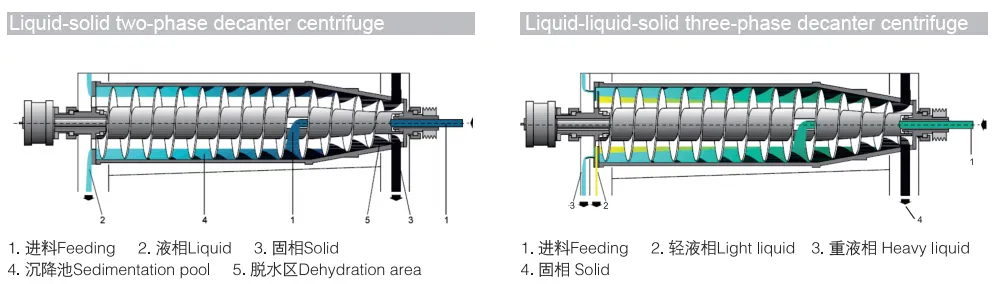

How the Decanter Process Works:

* 1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

* 2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

* 3: The bowl rotates at high speeds to induce centrifugal forces.

* 4: High speed rotation separates the solid material from the liquid in a matter of seconds.

* 5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

* 6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes

decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such

centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries.

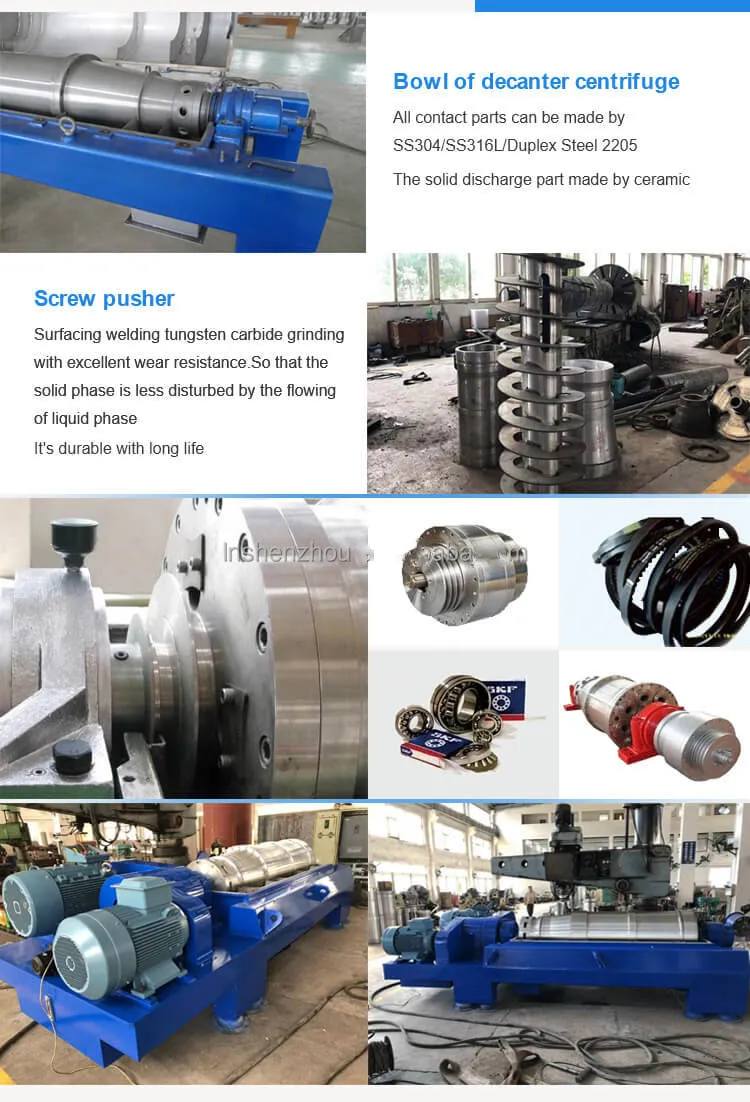

Details

Reference standard

Technical parameter

Name | Unit | Parameter |

Model | LWM760 | LWM760*3040-N |

Capacity | M3/h | 10-160M3/H |

Solid content | % | 0.5~20 |

Design Rotation speed | r/min | 2260Variable frequency speed regulation |

Working rotation speed | r/min | 2000Variable frequency speed regulation |

Max Separation factor | G | 2060/Variable frequency speed regulation |

Drum diameter | Mm | 760 |

Drum length | mm | 3040 |

Slag outlet | Wear-resistant ceramic or hard alloy | |

Mud scraping position of spiral blade | Surface spray welding tungsten carbide protective coating | |

Drum | AISI304/316 stainless steel/2205/2507Duplex steel | |

Screw | AISI304/316 stainless steel/2205/2507Duplex steel | |

Hood | AISI304stainless steel | |

Feed pipe, Drainage and slag discharge pipe | AISI304stainless steel | |

Machine base | High Quality Carbon Steel | |

Screw Torque | Nm | 25000 |

Differential speed | Rpm | 45-80/Stepless adjustable |

Differential adjustment accuracy value | Rpm | ≤1 |

Noise | dB(A) | 90 |

vibration | mm/S | 7.1 |

Motor power | KW | 185(380/3/50HZ) |

explosion protection level | EEx e II T3 | |

Rated voltage | V | 600 |

Protection class | IP | 56 |

Insulation class | F | |

Frequency conversion electric control cabinet | 760 | ZK1 |

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2200 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

If you want to know more please contact me:Cathy