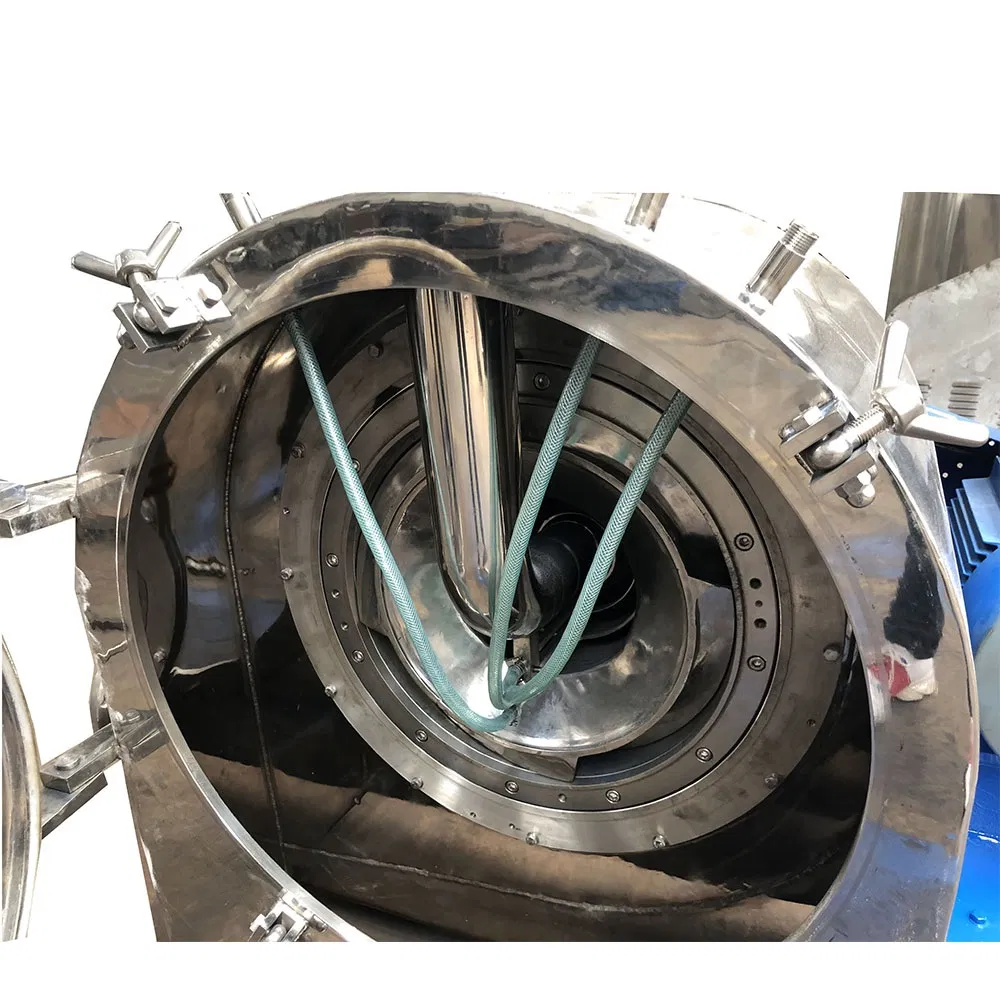

Small Salt Separator Worm Screen Scroll Centrifuge Machine Industrial Sea Salt Centrifuge

SHENZHOU horizontal screen scroll centrifuge has the advantages of large production capacity, good solid phase dehydration, low energy consumption and light weight.

Widely used in chemical, food, pharmaceutical and mining industries, and is suitable for the separation of solid-phase suspensions containing coarse crystals and short fibers.

Especially suitable for separating suspension of easy dehydration and high concentration.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

SEA SALT CENTRIFUGE MAIN FEATURES

1. Strong pertinence to materials, the crystal size is between 0.05-10mm

2. Continuous operation, Screw unloading, Large production

3. The solid phase has low moisture content, good washing effect and high separation efficiency

4. Dedicated filter screen, material optional, filter screen thickness up to 0.5mm, longer service life

5. Stepless speed regulation of drum speed

6. Simple and reliable lubrication

7. Compact structure, easy operation and maintenance

8. Safety protection: speed detection, oil-free protection, motor overload and overheat protection, spiral zero differential protection.

![Small Salt Separator Worm Screen Scroll Centrifuge Machine Industrial Sea Salt Centrifuge]()

LWL Series Screw Screen Centrifuge has been successfully used in the following:

LWL series has hundreds of cases in the waste salt treatment industry, including sodium chloride, sodium sulfate, ammonium chloride, ammonium sulfate, ferric chloride, and ferrous chloride. In addition, we have rich experience in plant extraction (tea, ginkgo, iron powder, kudzu root, hemp leaves, etc.), magnesium sulfate, copper sulfate, sodium gluconate, sodium metabisulfite, marine snowmaking, and other industries. Welcome customers from related industries to inquire.

The improvements made by SHENZHOU in ammonium sulfate, ammonium chloride, ammonium thiocyanate, sodium chloride and other waste

1. The feeding pipe device is improved, the cloth is more uniform, and the equipment operation is more stable;

2. The lubrication system is improved, the lubrication is more adequate and reasonable, and the bearing weight is increased;

2. The lubrication system is improved, the lubrication is more adequate and reasonable, and the bearing weight is increased;

3. Improve the bearing sealing system and adopt labyrinth oil seals to prevent mother liquid from entering the lubrication system;

4. The drum spiral is treated with nitriding and wear-resisting, and the service life is longer.

5. The discharging system is improved, and a scraper device is added to prevent the silo from accumulating.

Adipic Acid | Potash | Rock Salt | Date Stones |

Salt Cake | lon Excgange Resin | Sodium Nitre | Polystyrene Alcohol |

Arsenic Triazole | Sodium Chloride | Sodium Perborate | Sodium Thiosulphate |

Ah-salt | Anth Racene | Nylon Chips | Copper Sulphate |

Naphthenic Sulfonic Acid Ester | Iron Sulphate Hepta Hydrate | Hops From Dichlorc Methare | Ammonium Thiosulphate |

Greaves | Sodium Chlorate | Citric Acid | Tarteric Acid |

Aminiacetic Acid | Aspirin | Oxalic Acid | Crystal Soda |

Gun Powder | Lactose | Sodium Sulphate | Potash Alum |

Regenerated Rubber | Sodium Formate | Polymethacrylate | Tin Sulphate |

Ammonium Persulphate | Bisphenol | Sodium Sulphite | Dinitro Methylarlin |

Gypsum | Managanese Sulphate | Polysyrene | Potash Solvent Residue |

Silver Nitrate | Sodium Gliconate | Sodium Tetraborate | Trisodium |

Ammonium Phosphate | Borax | Two Nitro Methylaniline | Extraction from Methanol |

Urotropin | Methyl Cellulose | Disodium Phosphate | Potassium Bica Rbonate |

Sodium Acetate | Sodium Metaborate | Potassium Lore | Zinc Sulphate |

Ammonium Sulphate | Calcium Formiate | Potassium Chloride | Potassium Bichromate |

Sodium Phosphate | Monosod lumphasphate | Polyvinyl Chloride | Potassium Pensuphate |

Sodium Ca Rbonate | Sodium Nitrate | Potassium Sulphate | Fungal Mycel |

Specification

Model | Drum Dia (mm) | Drum Length (mm) | Speed (r/min) | Factor | Feeding (m³/h) | Power (kw) |

200 | 200 | 176 | 4000 | 1790 | 0.5-1.5 | 3 |

250 | 250 | 208 | 3500 | 1712 | 1-5 | 4 |

350 | 350 | 287 | 3000 | 1762 | 3-15 | 11 |

450 | 450 | 356 | 2600 | 1700 | 3-18 | 22 |

530 | 530 | 405 | 2200 | 1434 | 6-20 | 30 |

630 | 630 | 496 | 1850 | 1205 | 10-30 | 37 |

800 | 800 | 525 | 1500 | 1008 | 15-40 | 55 |

1000 | 1000 | 664 | 1000 | 560 | 20-50 | 90 |

Details

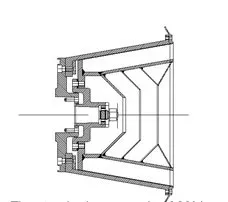

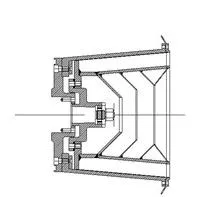

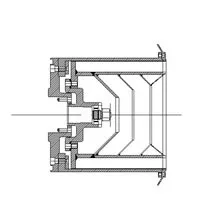

Structural Diagram

The drum/screw of the centrifuge can be customized in different angles according to customer requirements.

Material selection:

The material of the part in contact between the centrifuge and the material can be selected from stainless steel (304, 316L, 2205,etc.), Hastelloy, titanium and other corrosion-resistant materials according to customer requirements.![Small Salt Separator Worm Screen Scroll Centrifuge Machine Industrial Sea Salt Centrifuge]()

![Small Salt Separator Worm Screen Scroll Centrifuge Machine Industrial Sea Salt Centrifuge]()

![Small Salt Separator Worm Screen Scroll Centrifuge Machine Industrial Sea Salt Centrifuge]()

Material selection:

The material of the part in contact between the centrifuge and the material can be selected from stainless steel (304, 316L, 2205,etc.), Hastelloy, titanium and other corrosion-resistant materials according to customer requirements.

Configuration selection:

Explosion-proof configuration, gas-liquid separation device at the discharge port, washing device, vibration and main bearing temperature monitoring protection, etc.

The standard cone angle of 20° is suitable for the separation of most materials

The 10° cone angle is suitable for separation processes that require heating and washing effects

0° barrel drum is suitable for the separation of ice crystals and filber derivatives

WORKING PRINCIPLE

Under full speed operation: continuous feeding, washing, dewatering, unloading and other technological operations of the suspension.

The suspension enters the spiral cavity from the feed pipe, and enters the drum through the nozzle at the bottom of the screw head near the bottom of the cone.

Under the action of the centrifugal force field, the liquid phase in the slurry is separated by the creen set on the rotating wall When going out, the solid particles are trapped in the drum; at the same time, the solid particles in the drum move from the small end of the drum to the big end of the drum under the action of centrifugal force and the differential speed between the spiral and the drum.

The suspension enters the spiral cavity from the feed pipe, and enters the drum through the nozzle at the bottom of the screw head near the bottom of the cone.

Under the action of the centrifugal force field, the liquid phase in the slurry is separated by the creen set on the rotating wall When going out, the solid particles are trapped in the drum; at the same time, the solid particles in the drum move from the small end of the drum to the big end of the drum under the action of centrifugal force and the differential speed between the spiral and the drum.

During the movement, the centrifugal force increases rapidly due to the increase of the rotation diameter. The solid phase changes from the high moisture content solid phase when it initially enters to the low moisture content solid phase when it is discharged from the drum, thus realizing automatic and continuous solid and liquid phase separation.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap