Tubular Centrifuge GQ75

Tubular Centrifuge GQ75

Tubular Centrifuge GQ75 reaches a rotating speed of 20,000 r/min, ensuring precise and rapid bacterial separation. It achieves a maximum separation factor of 16,770, allowing for effective separation of fine suspensions. It includes a liquid-collecting tray for efficient collection of separated liquids. Our centrifuge supports PLC and touch screen installation for real-time speed and temperature monitoring.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

HIGH-SPEED TUBULAR SEPARATOR

High Speed Tubular Bowl Separator

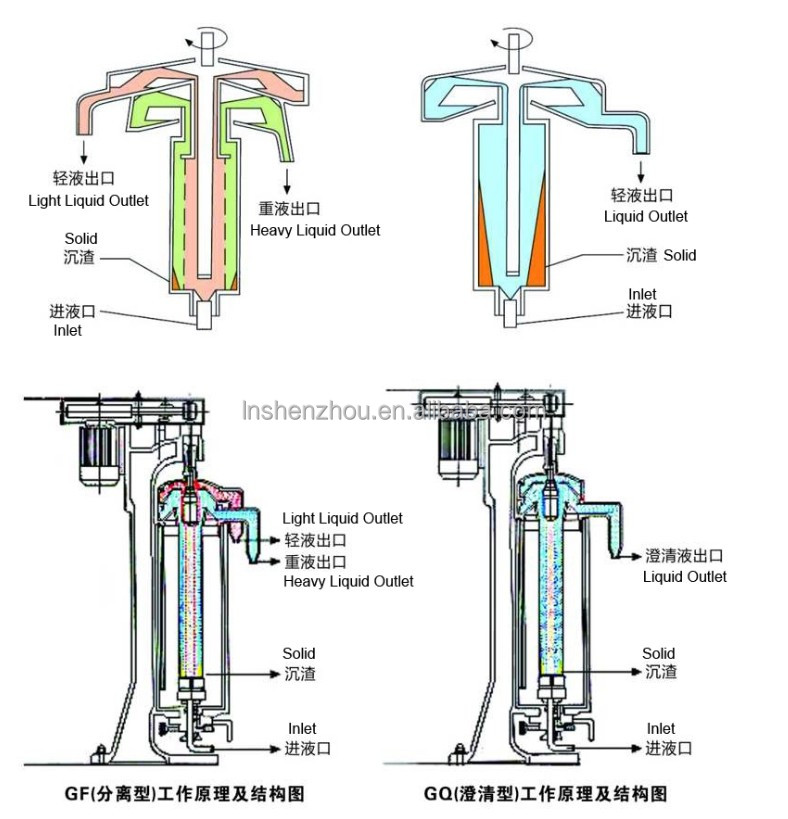

Structure and principle: The separator consists of machine body, driving part ,bowl, liquid collecting pan and liquid-in bearing seat etc. The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifugal force.

High Speed Tubular Bowl Separator

Structure and principle: The separator consists of machine body, driving part ,bowl, liquid collecting pan and liquid-in bearing seat etc. The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifugal force.

GF-for separation: Heavy liquid forms outer ring and light liquid forms inner ring. They flow to the top of the bowl and discharge from their respective outlet. And the little solid is settled on the wall of the bowl and discharged manually after the machine stops.

GQ-for clarification: Heavy solid is deposited on the inner wall of the bowl,and forms the sludge. And it will be

discharged by manual after the machine stops. The clear liquid flows out of outlet from the top of the bowl. It is mainly used for separating all kinds of suspension difficult to be separated, especially suitable for separation of solid-liquid suspension with light concentration, heavy viscosity, fine particles and very small differential gravity of the two phases. The motor connect with the big pulley and delivery the power to the spindle through the belt, tensioner and small pulley and rotate with the bowl in high-speed as the clockwise. The high speed tubular centrifuge is mainly used in liquid-solid separation, liquid-liquid-solid separation in bio, beverage, chemical industry. It is an ideal separation equipment by centrifuging, especially for those feeding with little gravity difference, and small dimension in diameter.

GQ-for clarification: Heavy solid is deposited on the inner wall of the bowl,and forms the sludge. And it will be

discharged by manual after the machine stops. The clear liquid flows out of outlet from the top of the bowl. It is mainly used for separating all kinds of suspension difficult to be separated, especially suitable for separation of solid-liquid suspension with light concentration, heavy viscosity, fine particles and very small differential gravity of the two phases. The motor connect with the big pulley and delivery the power to the spindle through the belt, tensioner and small pulley and rotate with the bowl in high-speed as the clockwise. The high speed tubular centrifuge is mainly used in liquid-solid separation, liquid-liquid-solid separation in bio, beverage, chemical industry. It is an ideal separation equipment by centrifuging, especially for those feeding with little gravity difference, and small dimension in diameter.

Features

* High-speed rotation

* Compact vertical bowl

* Corrosion-resistant rotor

* Manual batch cleaning

* Low mechanical stress

* Heat radiation support

* Durable construction

* High-speed rotation

* Compact vertical bowl

* Corrosion-resistant rotor

* Manual batch cleaning

* Low mechanical stress

* Heat radiation support

* Durable construction

Specification

If you want to know more please contact me:Cathy Tel:+8618941925296(WhatsApp)

https://www.lnszjx.com/

Details Images

Tubular centrifuge

Tubular centrifuge is the equipment motor transmits power to the belt pulley and main shaft on the machine head through the

transmission belt and the pressure pulley, thereby driving the drum to rotate at high speed around its own axis, forming a strong

centrifugal force field on the inner wall of the drum. The material is injected into the drum from the bottom inlet, and the

material liquid is forced to move in layers under the action of strong centrifugal force.

Motor

Domestic well-known brand motor,Customizable Siemens and ABB motors.Customizable explosion-proof motor.

PLC Control cabinet

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap