Industrial Coconut Oil Decanter Centrifuge - High Quality & Efficiency

Product advantages

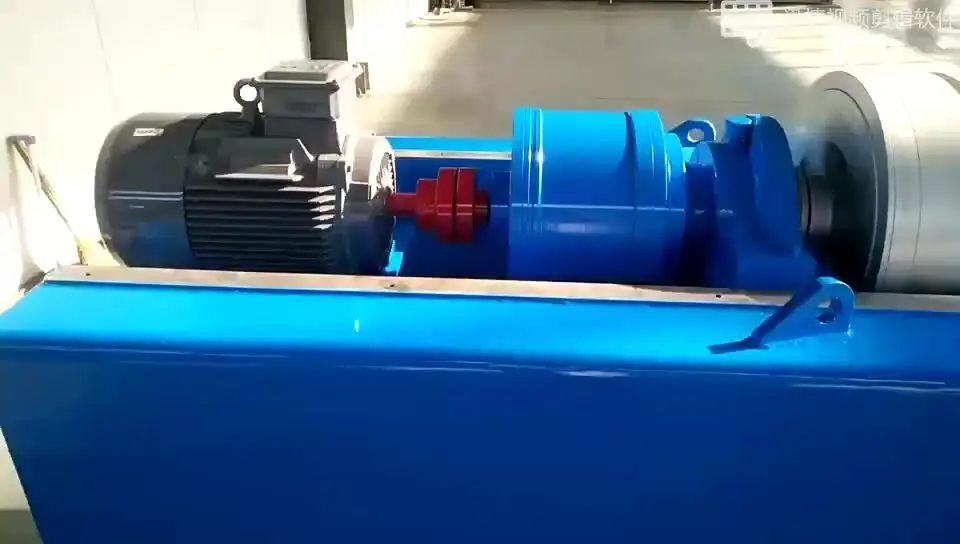

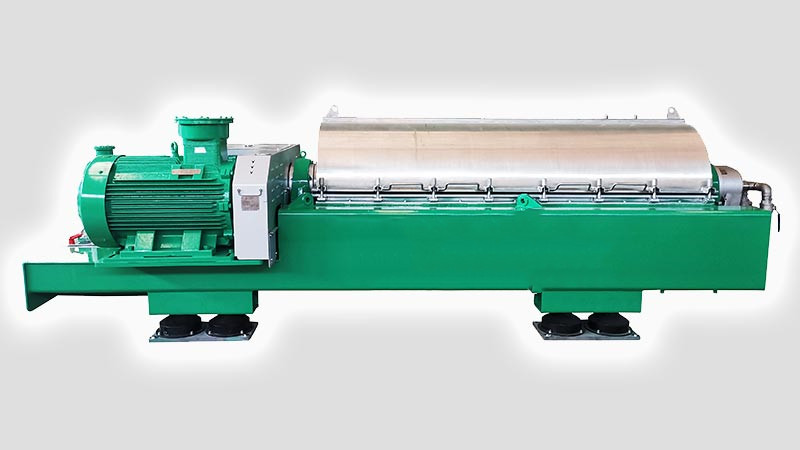

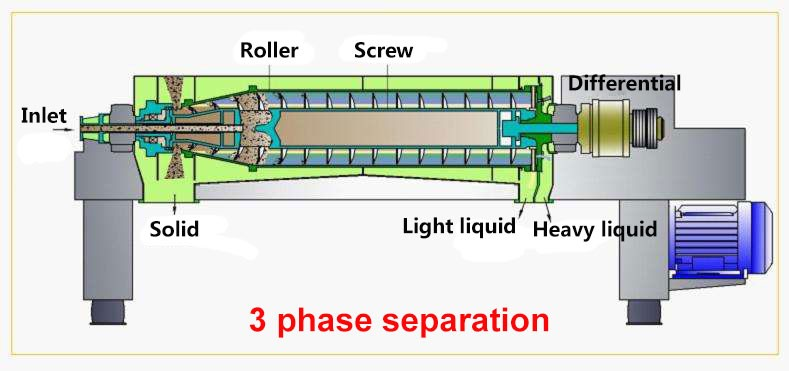

Our Industrial Coconut Oil Decanter Centrifuge is built with high-quality materials and precision engineering to ensure efficient and reliable performance. Its powerful decanter design allows for quick and easy separation of coconut oil from impurities, resulting in a pure and high-quality end product. With its innovative features and cutting-edge technology, our centrifuge offers unparalleled efficiency and productivity, making it the perfect choice for industrial coconut oil processing.

Team strength

Team strength is a crucial aspect of our Industrial Coconut Oil Decanter Centrifuge. Our dedicated team of experts works tirelessly to ensure the highest quality and efficiency of our product. With years of experience in the industry, our team brings a deep understanding of centrifuge technology, allowing us to deliver superior performance and reliability. We prioritize collaboration and communication within our team, enabling us to innovate and continuously improve our product. Trust in our team's expertise to provide you with a top-tier centrifuge that meets your industrial coconut oil processing needs efficiently and effectively.

Why choose us

At Industrial Coconut Oil Decanter Centrifuge, our team strength lies in our commitment to delivering high-quality and efficient products to our customers. Our skilled engineers and technicians work seamlessly together to ensure that each centrifuge meets the highest standards of performance and durability. With years of experience in the industry, our team is dedicated to providing top-notch customer service and technical support, ensuring that your centrifuge operates smoothly and effectively. Trust in our team's expertise and dedication to deliver a product that exceeds your expectations in quality and efficiency.

The application of technology plays an important role in the developing and manufacturing process of the product. Widely used in the application scene(s) of Separation Equipment, the product has won wide popularity. In today's era,Coconut Oil Decanter Centrifuge has proved its value in the field(s) of Separation Equipment. The design is the most striking aspect of Shenzhou. Its design comes from our designers who are sensitive to fashion and are know the commercial needs of the market very well. Also, Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge made of well-selected raw materials.

| Place of Origin: | China | Type: | Centrifuge |

| Condition: | New | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2021 |

| Warranty of core components: | 1 Year | Core Components: | Motor |

| Brand Name: | LYSZ | Voltage: | 220V |

| Weight: | 1850 | Dimension(L*W*H): | 2000*1200*1800mm |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company | Showroom Location: | None |

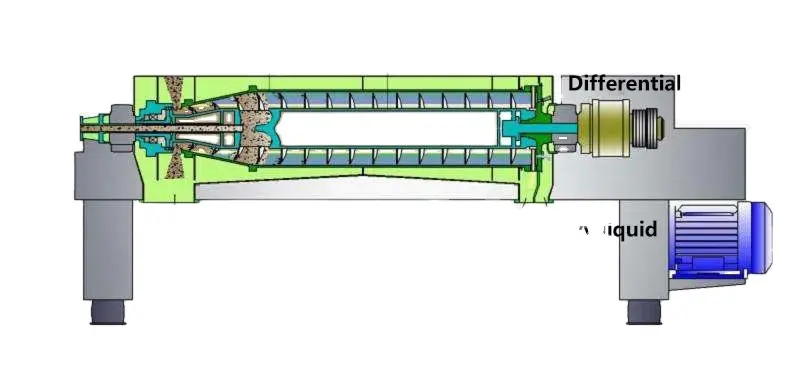

T series decanter centrifuge is usually used dewatering and thickening purpose. It is widely used for maximum dewatering requirements of municipal and industrial wastewater sludge.

The dewatering decanter centrifuge is designed for easy separation material include large particle size, high density difference of solid and liquid, low viscosity, high concentration, high treatment capacity and higher dryness than clarity. The materials like sludge or wastewater containing fine particles usually need to be added with flocculants to gather the fine particles condensed into large ones, and then dewatered with T series decanter centrifuge.

Model | SZLW-224ET | SZLW-364ET | SZLW-454ET | SZLW-554ET | SZLW-654ET | SZLW-764ET | |||||

Bowl Diameter | 220 mm (9 Inch) | 360 mm (14 Inch) | 450 mm (18 Inch) | 550 mm (22 Inch) | 650 mm (25.6 Inch) | 760 mm (30 Inch) | |||||

Bowl Length | 924 mm (36.4 Inch) | 1512 mm (59.5 Inch) | 1890 mm (74.5 Inch) | 2310 mm (91 Inch) | 2730 mm (82 Inch) | 3328 mm (131 Inch) | |||||

Bowl Speed | 4500 RPM | 3900 RPM | 3500 RPM | 3150 RPM | 2900 RPM | 2650 RPM | |||||

Max G Force | 2492 G | 3063 G | 3084 G | 3051 G | 3058 G | 3000 G | |||||

L/D Ration | 4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 4.4 | |||||

Main Motor | 11 KW | 22/30/37 KW | 37/45/55 KW | 55/90 KW | 90/110 KW | 110/132/160 KW | |||||

Back Motor | 5.5 KW | 7.5/11 KW | 11/15/22 KW | 15/37/45 KW | 18.5/22/37/55 KW | 22/37/75/90 KW | |||||

Beach Angle | 8.5° | ||||||||||

Drive Type | VFD+PLC+ HMI | ||||||||||

Bowl Material | SUS2304(Duplex Stainless Steel)/ SUS2205(Duplex Stainless Steel) Centrifugal Casting | ||||||||||

Screw Material | SUS2304(Duplex Stainless Steel)/SUS2205(Duplex Stainless Steel) | ||||||||||

Remarks | * The T-Series,Y-Series,C-Series decanter are interchangeable by replacing bowl assembly. * Final specifications should be based on commercial and technical offer. * Customized materials of the decanter centrifuge are available for option. | ||||||||||

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian