Industrial Decanter Centrifuge - Efficient Separation Equipment from China

Product features

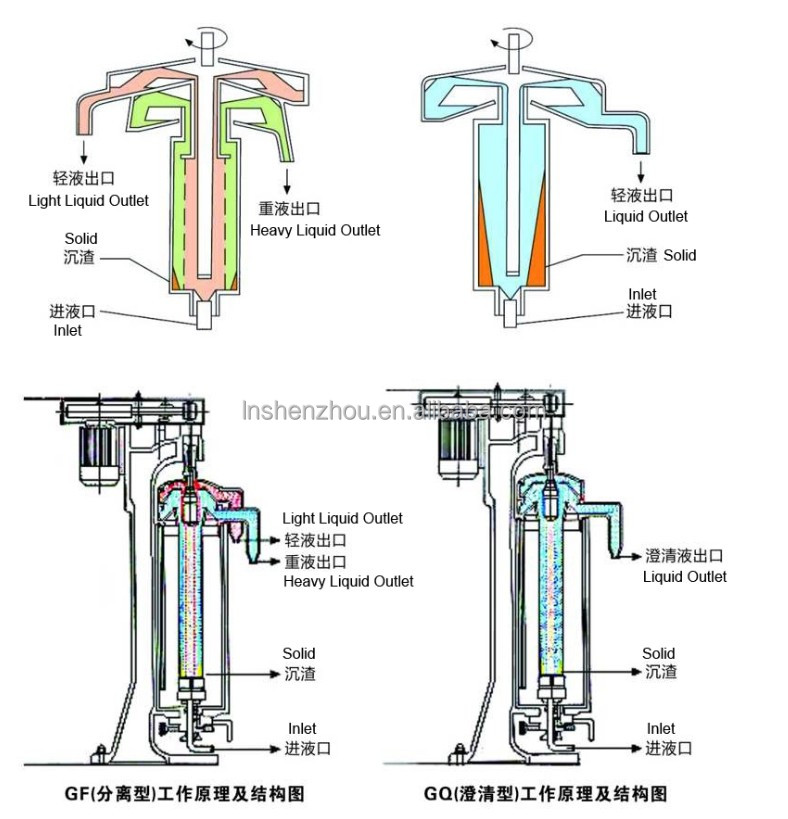

The industrial decanter centrifuge is a highly efficient separation equipment specifically designed for solid-liquid separation and liquid-liquid-solid separation with small solid particles and similar specific gravity differences. With a sliding bearing assembly, drum assembly, and liquid collecting plate assembly, this centrifuge generates a strong centrifugal force to separate materials. The GQ and GF models of the industrial decanter centrifuge are suitable for a wide range of applications in the food, pharmaceutical, chemical, and biological products industries, offering exceptional performance and reliability for various separation needs. From the clarification of pharmaceutical solutions to the separation of emulsions, this centrifuge provides high-quality results and is a valuable asset for businesses seeking superior separation equipment.

Team strength

At our company, we take pride in our team strength. Our skilled professionals work together seamlessly to design, manufacture, and deliver high-quality industrial decanter centrifuges from China. With years of experience in the industry, our team is knowledgeable, dedicated, and committed to providing efficient separation equipment that meets the needs of our customers. We value collaboration, innovation, and excellence, ensuring that our products are reliable, durable, and cost-effective. Trust in our team strength to deliver the best solutions for your separation needs.

Enterprise core strength

Our team of dedicated professionals at Industrial Decanter Centrifuge is our greatest strength. With years of experience in the industry, our team is well-versed in the efficient operation and maintenance of separation equipment. Their expertise ensures that our products are of the highest quality and provide reliable performance for our customers. From research and development to customer service, our team works together seamlessly to deliver innovative solutions and exceptional support. Trust in our team's knowledge and commitment to excellence when choosing Industrial Decanter Centrifuge for all your separation equipment needs.

While Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd consciously carrying out personnel training and technological innovation, it also continuously strengthens external communication and exchanges to improve its own competitiveness. At Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd, it is our goal to provide the highest quality products and superior service to our customers, both being our top priority. So, shake hands with us, expand your business, and increase your clientele.

| Place of Origin: | China | Type: | Centrifuge |

| Condition: | New | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | New Product 2021 |

| Warranty of core components: | 1 Year | Core Components: | PLC, Engine, Motor |

| Brand Name: | LYSZ | Voltage: | Depend on model choosing |

| Power: | Depend on model choosing | Weight: | 450 |

| Dimension(L*W*H): | Depend on model choosing | Warranty: | 1 Year |

| Key Selling Points: | Easy to Operate | Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Showroom Location: | None |

Our tubular centrifuges have different types, one is GQ two-phase solid-liquid separation model, i.e. clarification type; the other is GF three-phase solid-liquid-liquid separation model, i.e. separation type.

The selection of model should be based on the actual material characteristics.

solid-liquid separation with small concentration, high viscosity, fine solid particles and small solid-liquid gravity difference.

For example, the clarification of various pharmaceutical solutions, such as glucose chlorhexidine, malic acid, various oral

liquids, and Rhizoma Menispermi clarification; coal tar, graphite slag removal, protein, algae belt, pectin extraction; molasses refining; blood separation, vaccine mycelium, various glucose sedimentation, paint, dye, resin, rubber solution purification, Traditional Chinese medicine: separation and clarification of plant extract.

difference in weight between two phases and liquid-liquid-solid separation containing a small amount of impurities. For example, transformer oil, turbine oil, lubricating oil, fuel oil, dye, grease, saponification. Purification of various micro powder materials various oral and pharmaceutical solutions, separation of plasma biopharmaceuticals and extraction of plasma from animal blood, purification of edible oil, caipan soaking solution, tea polyphenols, soybean phospholipid concentrate, oil-water separation and sewage treatment, etc.

Model | GF/Q45 | GF/Q75 | GF/Q105 | GQY125 | GQ150 |

Bowl diameter | 45 mm | 75 mm | 105 mm | 125 mm | 142mm |

Effective height in bowl | 280 mm | 430 mm | 730 mm | 735 mm | 700 mm |

Settling volume in bowl | 0.45 L | 2 L | 5.5 L | 7.4 L | 10 L |

Bowl speed | 0-28000 r/min | 16770 r/min | 16000 r/min | 15000 r/min | 14000 r/min |

Max separation factors | 0-19800 | 20000 | 15025 | 15500 | 15570 |

Nozzle diameter | 2.3 mm | 2.3.5 mm | 4.6.8.10 mm | 6.8.10 mm | 8.10.12 mm |

Inlet pressure | >0.05 Mpa | >0.05 Mpa | >0.05 Mpa | >0.05 Mpa | >0.05 Mpa |

Throughput | ≈100 kg/h | ≈500 kg/h | ≈1200 kg/h | ≈2000 kg/h | ≈3000 kg/h |

Motor type | Series motor | Y90S-2 | Y90S-2 | Y90L-2 | Y100L-2 |

Motor power | 0.6 kw | 1.5kw | 2.2 kw | 3.0 kw | 3.0 kw |

Motor speed | 0-4500 r/min | 2840 r/min | 2880 r/min | 2880 r/min | 2880 r/min |

Size | 580*650*750mm | 800*400*1200 mm | 800*700*1400 mm | 850*500*1600 mm | 800*700*1600 mm |

Weight | 120Kg | 300Kg | 400Kg | 610Kg | 520Kg |

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian