Best EFFICIENT SLUDGE THICKENING AND DEWATERING FOR THE ENVIRONMENT INDUSTRY Supplier

Centrifugation, an efficient solution to solve your dewatering and thickening tasks Centrifugation is a mechanical separation process in which two or more materials are separated using centrifugal forces. The demands of a centrifuge depend strongly on the specific application (e.g. flow rates and solids load), the material characteristics (e.g. particle size and abrasion behavior), and the operating environment (e.g. explosion-proof design).

Centrifuge Thickening and Dewatering

Centrifugal thickening and dewatering of sewage sludge is a high speed process that uses the force from rapid rotation of a cylindrical bowl to separate wastewater solids from liquid to produce a non-liquid material referred to as “cake.” Dewatering wastewater solids reduces the volume of residuals, improves operation, and reduces costs for subsequent storage, processing, transfer, end use, or disposal among other benefits. Centrifuges have been used in wastewater treatment since the 1930s.

Shenzhou for centrifuge thickening and dewatering provides:

A description of centrifuge thickening and dewatering

Applicability to wastewater treatment plants

Advantages and disadvantages of centrifuge thickening and dewatering

Design criteria

Performance capabilities and data

Operation and maintenance information

Costs

Dewatering offers the following advantages:

Reduces volume, saving money on storage and transportation.

Eliminates free liquids before landfill disposal.

Reduces fuel requirements if the residuals are to be incinerated or heat dried.

Produces a material, which, when blended with a bulking agent, will have sufficient void space and volatile solids for composting.

Eliminates ponding and runoff, which can be a problem when liquid is land applied on the surface rather than injected.

Optimizes air drying and many stabilization processes.

Reduces fuel requirements if the residuals are to be incinerated or heat dried.

Produces a material, which, when blended with a bulking agent, will have sufficient void space and volatile solids for composting.

Eliminates ponding and runoff, which can be a problem when liquid is land applied on the surface rather than injected.

Optimizes air drying and many stabilization processes.

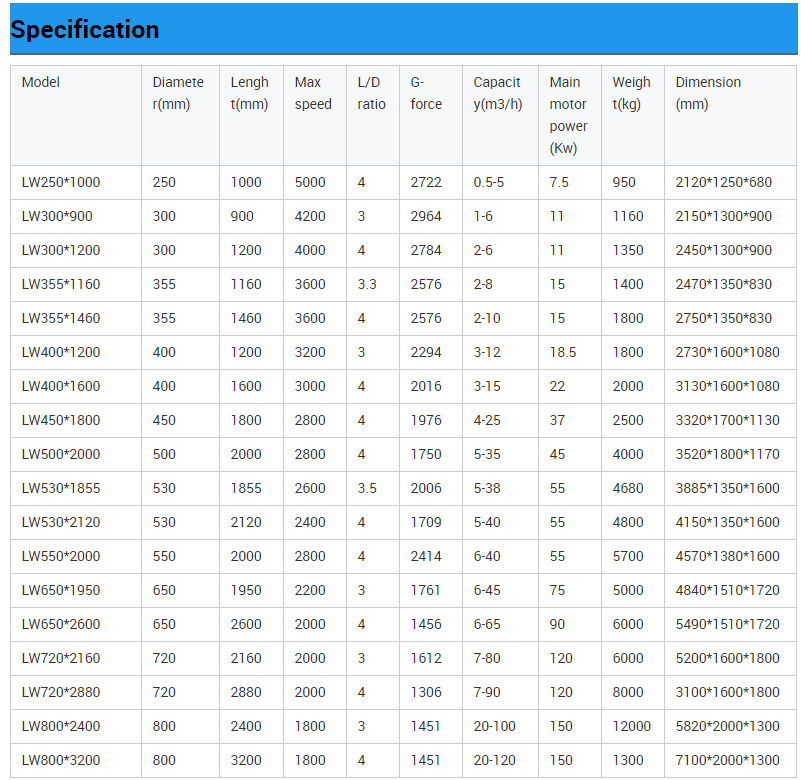

Technical Parameter: