Wastewater Centrifuge | Sludge Dewatering & Thickening Supplier & manufacturers | Shenzhou

Wastewater Centrifuge | Sludge Dewatering & Thickening

A sludge dewatering or sludge thickening centrifuge is a decanter-type horizontal de-sludger that can remove water from slurries to thicken the sludge. In other words, a heavy-duty industrial centrifuge dewaters and concentrates (thickens) the sludge, also known as a sludge thickening machine. These machines are available in different sizes to continuously process large quantities of sludge-laden water.

Livestock farm manure, municipal sewage, car washes, and oilfield drilling mud produce wastewater with high sludge content of up to 50%. The primary objective of such applications is to reduce the sludge volume to minimize handling and disposal costs. The recovered water is often clean enough to be reused or discharged with minimal environmental impact.

Decanter for Wastewater Sludge Thickening:

Wastewater from mining applications is one such example. This stream contains minute silt and clay particles that are difficult to separate with a wastewater decanter. A high-speed disc centrifuge has sufficient g-force to pull out these particles and clarify the water.

Separator for Industrial Oily Wastewater

Industrial wastewater often carries oil in addition to sludge. This oily water is challenging because it cannot be disposed of in standard drains. A three-phase industrial centrifuge separates the oil from the water, making it disposable.

Industrial cleaning fluid containing shop-floor sludge and oil from the manufacturing run-off is ideal for separation with a liquid-liquid-solid separator.

Benefits

Centrifuge offers many benefits compared to other dewatering and separation technologies. A brief description of some of the advantages follows.

Reduced Transportation and Disposal Expenses

Centrifuges produce dry sludge cake, which significantly reduces transportation costs (up to 50%). Dry sludge also reduces disposal costs because the disposal volume is a fraction of the wet sludge.

Equipment Durability and Longevity

Industrial decanters are heavy-duty machines that have long service lives. Their material of construction (Stainless Steel) provides corrosion resistance in corrosive processing applications.

These centrifuges have superior erosion protection in critical areas for enhanced wear protection. It is not uncommon for these dewatering machines to operate for decades without the need for replacement or even significant rebuilds.

Low Operating Expense

Unlike belt and filter presses, centrifuges do not use filter media, which significantly benefits these machines’ users. Also, this eliminates the labor cost related to media replacement.

The only operational expense associated with centrifuges is maintenance. The only parts that need occasional replacement are the bearings because a decanter has fewer moving parts than filter presses.

Minimized Operator Requirements

Most sludge-thickening and dewatering centrifuges are fully automatic. The control systems have built-in sensors with self-correcting features to allow operator-free processing.

Other methods mentioned above need manual service to replace media or perform other periodic functions.

Compact Size for Processing Capacity

Centrifuges are compact when compared to other dewatering equipment. For equivalent capacity, a decanter footprint is often a fraction of other comparable machines. This small size makes them a viable option for wastewater de-sludging in confined areas in treatment plants.

The centrifuge equipment’s compact size means that its location can be changed or moved to the worksite for ease of use and flexibility.

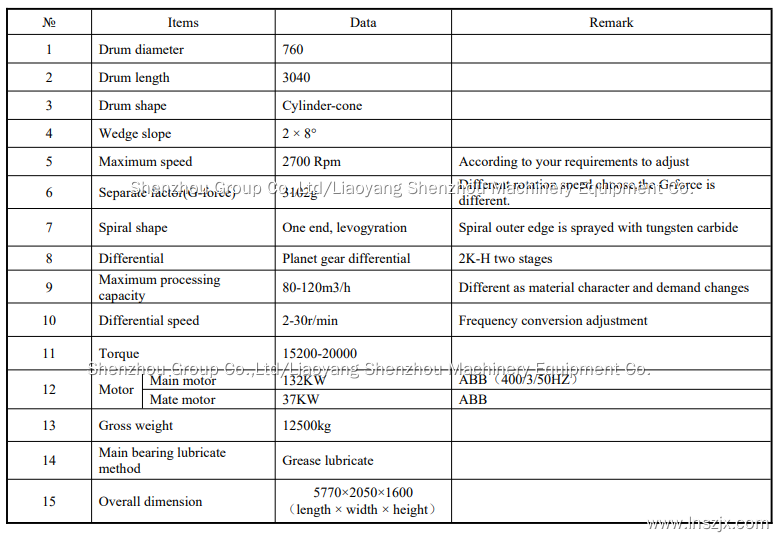

Specifications and Sizing

Centrifuge specifications and sizing depend highly on the manufacturer and the customer’s capacity throughput requirements. Listed below are some specific technical details and sizes of the commonly used dewatering separators from

SHENZHOU

Technical Parameter of Decanter for Wastewater Sludge Thickening: