Shenzhou - Pressure Brewer Yeast Spray Drying Equipment For Chemical Industry Drying & granulator Machine

Our engineers and technicians have deep insight into the new technological developments. So far, we have been adopting the upgraded technologies maturely.It is popular in the application field(s) of Pressure Brewer Yeast Spray Drying Equipment For Chemical Industry.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Products Description

Product Description

ZPG series of spraying and drying machine for Chinese medical extract

Brief introduction: In this machine, the fully-closed structure is adopted, all parts are made of stainless steel, and there is the 3-stage purifying device. After the filtering, the air meets the 100000-grade standard. There are cooling devices for the reactor, the temperature of the container wall is less than 80℃, and even the raw products are stayed on the wall, will not be burned. The powder rate is as high as more than 95%, and there is no powders mixing or wall hanging.

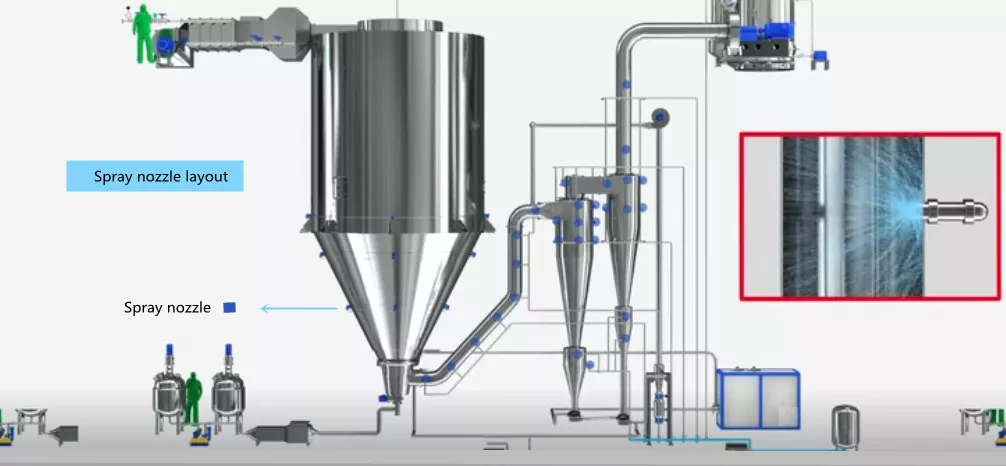

Working principle:In this machine, the centrifugal spraying and drying technology is adopted. With the high-speed centrifugal atomizer, after the spraying, powders are atomized, can be contacted with hot air completely, and the drying is completed instantly.

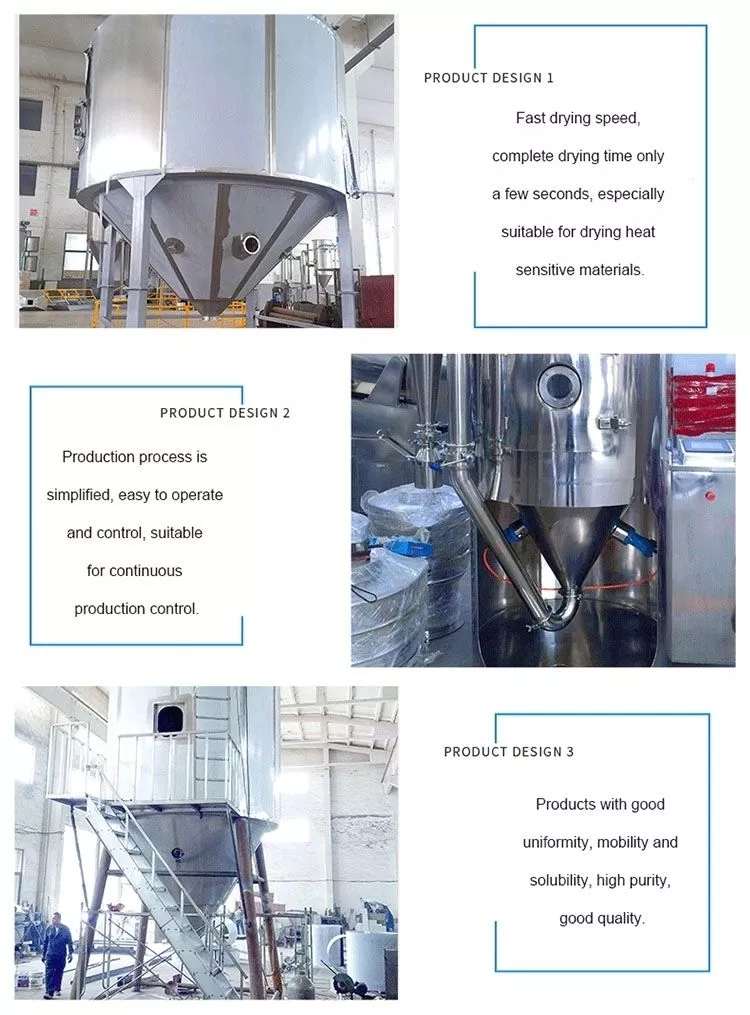

Details Images

Features:

3.With the flushing device, the machine can be applied for the drying for many kinds of products.

4.The wet-type dust collecting is adopted, which meets the environment protecting standard.

5.There is the air cleaning device.

6.In the atomizer, the variable-frequency speed regulating is equipped.

7.There is the touch screen and the PLC.

8.CIP

1.With the 3-stage purifying device, the air meets the 100000-grade standard.

2.There are cooling devices for the reactor, the temperature of the container wall is less than 80℃, and even the raw products are stayed on the wall, will not be burned.

3.With the flushing device, the machine can be applied for the drying for many kinds of products.

4.The wet-type dust collecting is adopted, which meets the environment protecting standard.

5.There is the air cleaning device.

6.In the atomizer, the variable-frequency speed regulating is equipped.

7.There is the touch screen and the PLC.

8.CIP

Specification

S.N. | Items | Requirement |

1 | Raw product | Concentrated liquid from fruit puree |

2 | Air temperature at inlet | 150 ~ 200℃ |

3 | Air temperature at outlet | 80 ~ 100℃ |

4 | Dewatering | 90Kg/h |

5 | Water content in raw product | 80 ~ 90% |

6 | Water content in final product | 1 ~ 3% |

7 | Heating | Electric heating: 210Kw / Natural gas: 220m2 |

8 | Electric high-speed centrifugal atomizer | 1 set |

9 | Vibrator for tower wall | 3pcs |

10 | Total power | 38.25Kw (Electric heating of 270Kw is not included) |

11 | Gas furnace(optional) | 600000kilocalorie |

12 | Material | Stainless steel 304 Thickness of inner plate in the drying tower: 3mm Insulation: 80mm Outer seal: 1.2mm (Stainless steel 304) |

Packing & Delivery

wooden case

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

FAQ

1. who are we?

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2018,sell to North America(30.00%),South America(10.00%),Southeast Asia(10.00%),South Asia(7.00%),Eastern Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Central America(5.00%),Northern Europe(5.00%),Southern Europe(5.00%),Africa(3.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Separator,Centrifuge,Packing & Filling,Drying,Tabling Machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap