Shenzhou - Olive oil process machines product line Production Line equipment

In our company, we have been updating our technologies to manufacture the product.With those properties, Olive oil process machines product line has been functioning very well in the application field(s) of Oil Pressers.

5.0

Customization:

Customized logo (Min. Order: 1 Sets),Customized packaging (Min. Order: 1 Sets),Graphic customization (Min. Order: 1 Sets)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

After long-term exploration and hard work, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd have launched Olive oil process machines product line that lead the industry. The Olive oil process machines product line has the significance of taking a leap forward and injects new impetus into the development of the industry. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has successfully expanded its business in market in the past few years and it is very possible for the company to have a better development in the future.

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company | Showroom Location: | None |

| Condition: | New | Usage: | OLIVE OIL |

| Automatic Grade: | Automatic | Place of Origin: | China |

| Brand Name: | Shenzhou | Voltage: | Country |

| Weight: | 12000 KG | Warranty: | 1 Year |

| Key Selling Points: | High-accuracy | Marketing Type: | Hot Product 2019 |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | Motor, PLC |

| Oil type: | Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL, Palm Oil | Max Capacity: | 10000 |

| After Warranty Service: | Field maintenance and repair service | Local Service Location: | None |

| After-sales Service Provided: | Video technical support, Online support | Certification: | ce |

Product Description

Olive oil process machines product line

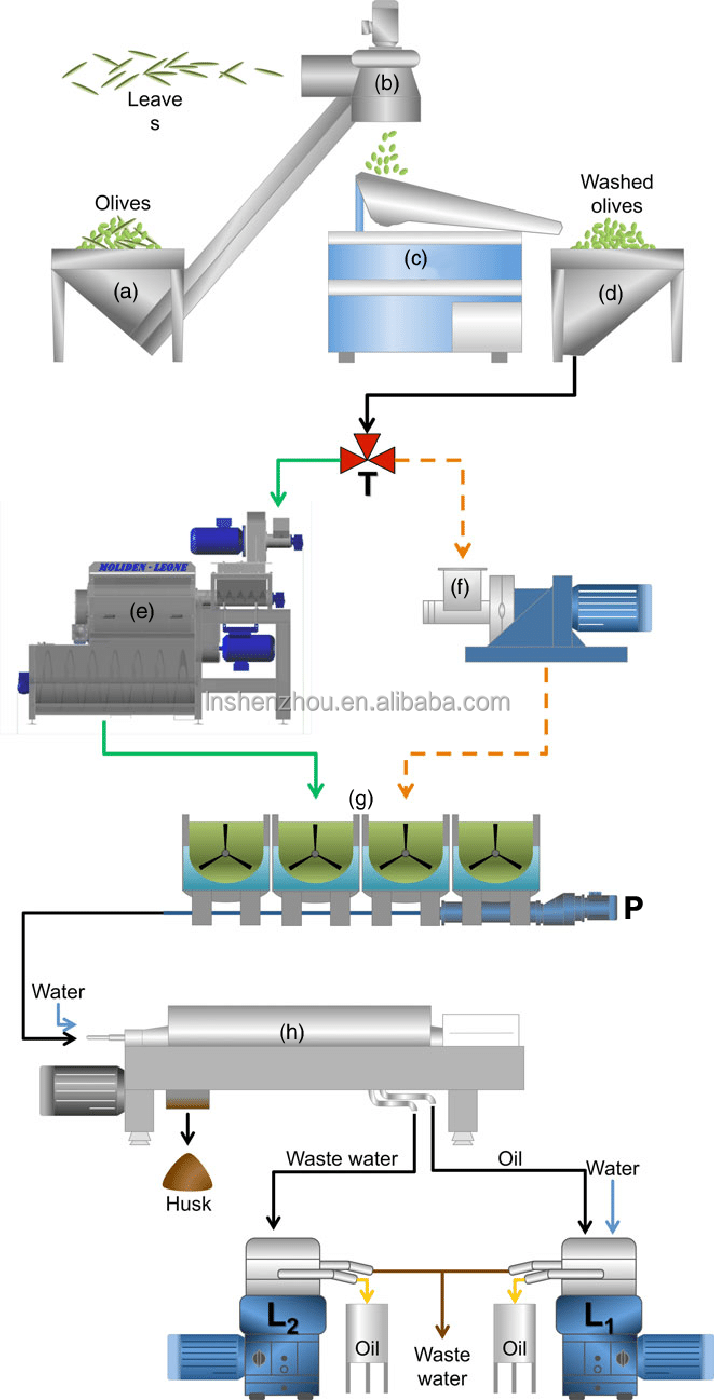

The 5 processing steps: from olive to extra virgin olive oil

How to cultivate the olive tree to extract an excellent extra virgin olive oil:

The 5 steps for the production of olive oil

Olive Oil production is mainly divided into 5 phases.

1.Collection

Harvesting is one of the most delicate and decisive steps to obtain an excellent quality olive oil.

Generally it is facilitated with the use of nets lying on the ground under the plants that allow to easily collect the fallen

product or facilitated by any mechanical equipment.

2.Washing and pressing

After harvesting the olives are weighed and subjected to an abundant washing in water. This process is carried out with a special washing machine with a constant flow of water that invests the olives.

The crushing system of the milled olives is the most ancient instrument, conceptually derived from the millstones used since the Hellenic age. Today, however, many mills use the most modern hammer crushers, which break the olives by pushing them violently against a metal grid.

3.Kneading

After pressing the olive paste is subjected to the kneading operation which consists of a continuous and slow mixing of the dough.

The kneading phase is an essential moment for the subsequent extraction of the oil from the olive paste. In fact, the kneading allows the olive paste to reach the optimal temperature in which the natural enzymes present are able to fully activate.

4.Extraction

The extraction phase consists in the separation of the oil from the solid fraction.

This phase can be performed for:

* Pressure;

* Centrifugation;

* Percolation.

5.Separation

In this final phase we proceed to separate the olive oil from the water thanks to the centrifugal force.

Olive Oil production is mainly divided into 5 phases.

1.Collection

Harvesting is one of the most delicate and decisive steps to obtain an excellent quality olive oil.

Generally it is facilitated with the use of nets lying on the ground under the plants that allow to easily collect the fallen

product or facilitated by any mechanical equipment.

2.Washing and pressing

After harvesting the olives are weighed and subjected to an abundant washing in water. This process is carried out with a special washing machine with a constant flow of water that invests the olives.

The crushing system of the milled olives is the most ancient instrument, conceptually derived from the millstones used since the Hellenic age. Today, however, many mills use the most modern hammer crushers, which break the olives by pushing them violently against a metal grid.

3.Kneading

After pressing the olive paste is subjected to the kneading operation which consists of a continuous and slow mixing of the dough.

The kneading phase is an essential moment for the subsequent extraction of the oil from the olive paste. In fact, the kneading allows the olive paste to reach the optimal temperature in which the natural enzymes present are able to fully activate.

4.Extraction

The extraction phase consists in the separation of the oil from the solid fraction.

This phase can be performed for:

* Pressure;

* Centrifugation;

* Percolation.

5.Separation

In this final phase we proceed to separate the olive oil from the water thanks to the centrifugal force.

Leaf removal:

Remove branches and leaves

Vertical elevator

Transport the olive fruit to the next step

Washing machine

Wash off the dust on the surface of the olive fruit

Hammer crusher

Crush the olives into paste

Screw conveyor.

Delivery the olive paste to the next step

Malaxing machine

Olive paste and water fusion

The decanter is the heart of the process, whether batch or continuous. Depending on the customer’s specific requirement,

both processes can be designed as two-phase or three-phase processes. The performance range of Westfalia Separator comprises lines including planning, engineering and control for processing between 30 and 240 tons of olives per day

both processes can be designed as two-phase or three-phase processes. The performance range of Westfalia Separator comprises lines including planning, engineering and control for processing between 30 and 240 tons of olives per day

.

You can choose three phase decanter or two phase decanter.

The last step is disc separator remove the sludge and water,at last get clear olive oil.

Specification

item | value |

Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

After Warranty Service | Field maintenance and repair service |

Local Service Location | None |

Showroom Location | None |

Condition | New |

Usage | OLIVE OIL |

Automatic Grade | Automatic |

Place of Origin | China |

Brand Name | Shenzhou |

Voltage | Country |

Weight | 12000KG |

Certification | ce |

Warranty | 1 Year |

Video technical support, Online support | |

Key Selling Points | High-accuracy |

Marketing Type | Hot Product 2019 |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Warranty of core components | 1 Year |

Core Components | Motor, PLC |

Oil type | Flax Seed Oil, Soybean Oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, sunflower seed oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL, Palm Oil |

Max Capacity | 10000 |

Plant Benefits:

1.Olive oil lines for batch and continuous processing

2.Design concepts for different capacities

3.Adjustment of machine parameters according to changes in product and process conditions

4.Simple control and handling Robust, sturdy quality “Made in China”

5.High efficiency – fast pay back time

6.Maximum product yield and minimum residual oil content in the pomace through innovative centrifugal technology

7.Low fresh water consumption with minimum waste water reduces environmental pollution

8.No manual cleaning of the disc stack thanks to the self-cleaning bowl of the separator

9.Polishing separator for minimum oil losses during discharge and automatic disc cleaning

10.Minimum oil oxidation thanks to centripetal pump 1-2% more oil yield than comparable machines

11.No additional separator needed for waste water because of adjustable paring tube Improved malaxer for high quality olive oil

11.Customer proximity and on-site service due to world-wide sales and service network In-depth know-how: more than 50 years of experience in the development and design of centrifuges

Intensive research in centrifugal separation technology for producing PET plastic containers and bottles in all shapes.

1.Olive oil lines for batch and continuous processing

2.Design concepts for different capacities

3.Adjustment of machine parameters according to changes in product and process conditions

4.Simple control and handling Robust, sturdy quality “Made in China”

5.High efficiency – fast pay back time

6.Maximum product yield and minimum residual oil content in the pomace through innovative centrifugal technology

7.Low fresh water consumption with minimum waste water reduces environmental pollution

8.No manual cleaning of the disc stack thanks to the self-cleaning bowl of the separator

9.Polishing separator for minimum oil losses during discharge and automatic disc cleaning

10.Minimum oil oxidation thanks to centripetal pump 1-2% more oil yield than comparable machines

11.No additional separator needed for waste water because of adjustable paring tube Improved malaxer for high quality olive oil

11.Customer proximity and on-site service due to world-wide sales and service network In-depth know-how: more than 50 years of experience in the development and design of centrifuges

Intensive research in centrifugal separation technology for producing PET plastic containers and bottles in all shapes.

Company Profile

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.Our products are exported to many countries and areas, such as the USA, Korea, India, Indonesia,Thailand, Vietnam,Japan, Denmark,Romania, Bulgaria,Russia,South Africa, and so onAt the same time,our product with best prices and good quality,welcome to Shenzhou!

FAQ

1. who are we?

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Liaoning, China, start from 2018,sell to South America(12.00%),Southeast Asia(10.00%),Northern Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),South Asia(8.00%),Central America(6.00%),North America(5.00%),Eastern Europe(5.00%),Africa(5.00%),Oceania(5.00%),Eastern Asia(5.00%),Western Europe(5.00%),Mid East(4.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,Separator,Packing machine,Drying machine,Filling & Sealing machine

4. why should you buy from us not from other suppliers?

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute. With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,CPT,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap