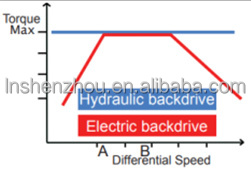

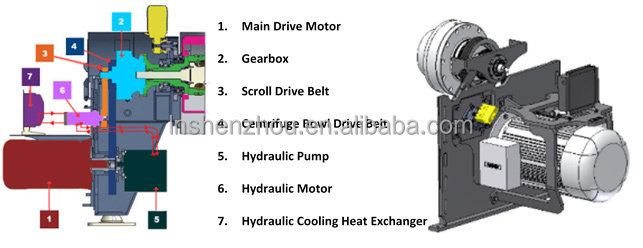

DRW Decanter Centrifuge Machine Components / Scroll Back-drive Transmission OptionsHaving the ability to adjust the scroll differential speed and maintain consistent back-drive torque control is essential to

optimal performance. In centrifuge operation, the torque on the scroll back-drive expresses the pressure applied to squeeze theliquid phase out of the solid phase. Too much scroll back-drive torque and the liquid will come rushing out the solids discharge, not enough and you won’t get a SHENZHOU Hydraulic back-drives are typically preferred over electric back-drives because they offer better torque control and a flat performance curve per the graph. However SHENZHEN offers the DRW range of decanter centrifuges witha selection of different back-drive transmission types to meet specific customer and / or application requirements.

Shenzhou - DRYCAKE DR Decanter Centrifuge Decanter centrifuge

Technologies play an important role in the development and manufacturing of DRYCAKE DR Decanter Centrifuge.In the field(s) of Separation Equipment , it functions extremely well and has received wide popularity.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

In order to better adapt to the diversified needs of customers,Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has been working hard to develop products. To meet various needs of customers, we supports customized DRYCAKE DR Decanter Centrifuge. Our capable staff has been devoted to the improvement and upgrades of technology.In the Separation Equipment,the product is widely used.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | decanter separator | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Hot Product 2021 | Warranty of core components: | 3 years |

| Core Components: | PLC, Motor | Brand Name: | Shenzhou |

| Voltage: | 110,220,380,440,460v | Power: | Depend on model choosing |

| Weight: | 1000 | Dimension(L*W*H): | Depend on model choosing |

| Warranty: | 12 months | Key Selling Points: | Energy saving |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company | Showroom Location: | None |

Product Description

Langley Separation and Process offers the complete range SHENZHOU DRW Model horizontal decanter centrifuges incorporating decades of mechanical knowledge and process experience to provide an effective, low-maintenance solution for continuous liquid-solids separation, liquid clarifying and/or solids dewatering with advanced mechanical features and superior processing performance.

The SHENZHOU DRW Decanter Centrifuges are available in a variety of configurations with capacities from 20-gpm to 800-gpm including two phase (liquid/solid) and three phase separation (liquid/liquid/solid) designs. This makes the range of SHENZHOU DRW Decanter Centrifuges very versatile and capable of adapting to a wide range of industrial and municipal applications. The automated controls also make these machines easy to adjust over a wider range of process conditions and require little operator attention to maintain process parameters. Our centrifuges are designed for high performance and reliable operation under the most strenuous of conditions.

The SHENZHOU DRW Decanter Centrifuges are available in a variety of configurations with capacities from 20-gpm to 800-gpm including two phase (liquid/solid) and three phase separation (liquid/liquid/solid) designs. This makes the range of SHENZHOU DRW Decanter Centrifuges very versatile and capable of adapting to a wide range of industrial and municipal applications. The automated controls also make these machines easy to adjust over a wider range of process conditions and require little operator attention to maintain process parameters. Our centrifuges are designed for high performance and reliable operation under the most strenuous of conditions.

Standard available automation package feature back-drive controls plus PLC with color HMI and VFD motor controls. Custom automation and programming of additional process controls is available. Complete custom skid packages with common structural steel skid with pumps, sludge conveyor, hydraulic unit, and control panel with all components pre-mounted, wired, and piped for turnkey operation and portability are also available.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

DRW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

DRW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

DRW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

DRW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

DRW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

DRW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

DRW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

DRW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

DRW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

DRW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

DRW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

DRW550*2000 | 550 | 2200 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

DRW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

DRW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

DRW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

DRW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

DRW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

DRW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

15 Reasons to Choose a SHENZHOU DRW Decanter Centrifuge:

1. Available in 2-Phase and 3-Phase design configurations for separation of liquid/solids or liquid/liquid/solids

2. The dedicated electronic DPC (Decanter Process Controller) automatically manages the process cycle and safely controls the machine while maximizing the process potential of the DRW Decanter

3. Replaceable solid discharge erosion resistant wear bushings are easily accessible given the unique rotating assembly cover design simplifying maintenance and reducing downtime

4. Adjustable Liquid discharge level plates are easily accessible and adjusted due to the unique rotating assembly cover design simplifying maintenance and reducing downtime

5. A unique sludge discharge cover scraper assembly prevents sludge from accumulating on the inside of the cover and blocking the solid discharge of the machine

6. Hydraulic and electric scroll back-drive transmission group options including an energy recovery system during machine operation which reduces the energy consumption of the DRW Decanter

7. Scroll features a sludge baffle disc which increases the working capacity of the DRW Decanter and improves separation performance

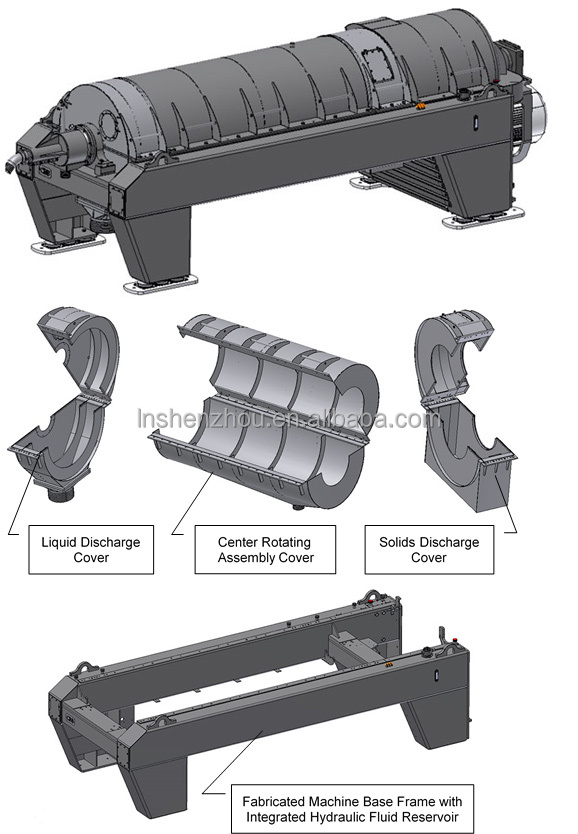

8. Four (4) piece machine rotating assembly covers with hydraulic actuators simplifies the operator’s job making inspecting and maintaining the specific sections of the rotating assembly easy and convenient

9. Rotating assembly group is easily extracted from above the machine simplifying maintenance and reducing removal time

10. Head-walls and bowl sections made from high strength forgings and centrifugal castings to improve resistance and homogeneity of bowl structure

11. Scroll features solid stainless steel fabrication to improve resistance, stiffness and longevity

12. Heavy-duty DRW Decanter base frame fabrication dampens vibrations and minimizes vibration transmission to the machine mounting structure

13. Twenty (20) years of design and manufacturing experience in sludge separation processes assures customer satisfaction and meeting specific process and facility requirements

14. Optional remote monitoring and operational assistance reduces waiting time for resolution of possible problems

15. Technical service follow-up within 24 hours (in Italy or 48 hours abroad) when possible issues occur SHENZHOU provides a Toll Free: 8618041915856 technical support and resolution.

2. The dedicated electronic DPC (Decanter Process Controller) automatically manages the process cycle and safely controls the machine while maximizing the process potential of the DRW Decanter

3. Replaceable solid discharge erosion resistant wear bushings are easily accessible given the unique rotating assembly cover design simplifying maintenance and reducing downtime

4. Adjustable Liquid discharge level plates are easily accessible and adjusted due to the unique rotating assembly cover design simplifying maintenance and reducing downtime

5. A unique sludge discharge cover scraper assembly prevents sludge from accumulating on the inside of the cover and blocking the solid discharge of the machine

6. Hydraulic and electric scroll back-drive transmission group options including an energy recovery system during machine operation which reduces the energy consumption of the DRW Decanter

7. Scroll features a sludge baffle disc which increases the working capacity of the DRW Decanter and improves separation performance

8. Four (4) piece machine rotating assembly covers with hydraulic actuators simplifies the operator’s job making inspecting and maintaining the specific sections of the rotating assembly easy and convenient

9. Rotating assembly group is easily extracted from above the machine simplifying maintenance and reducing removal time

10. Head-walls and bowl sections made from high strength forgings and centrifugal castings to improve resistance and homogeneity of bowl structure

11. Scroll features solid stainless steel fabrication to improve resistance, stiffness and longevity

12. Heavy-duty DRW Decanter base frame fabrication dampens vibrations and minimizes vibration transmission to the machine mounting structure

13. Twenty (20) years of design and manufacturing experience in sludge separation processes assures customer satisfaction and meeting specific process and facility requirements

14. Optional remote monitoring and operational assistance reduces waiting time for resolution of possible problems

15. Technical service follow-up within 24 hours (in Italy or 48 hours abroad) when possible issues occur SHENZHOU provides a Toll Free: 8618041915856 technical support and resolution.

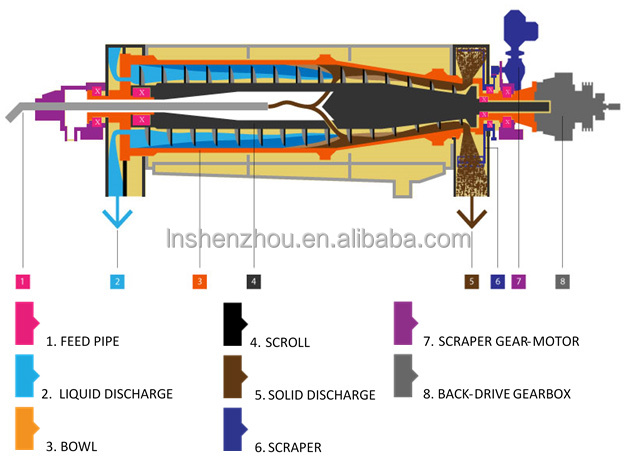

Characteristics of Two-phase Separation

SHENZHOU DRW Decanter Centrifuges allow separation between liquid and solid phases contained within a feed-slurry of industrial or municipal wastewater sludges or other industrial and/or food applications.

Inlet sludge, through feed pipe, will be conducted inside the bowl of the decanter and here separation of liquid phase from solid one will happen thanks to the action of centrifugal force. Liquid phase will be expelled from bowl front part thanks to specific level plates than can be adjusted on outlet diameter, while solid phase will be convoyed from the screw to exit openings on bowl rear part, where it will be then expelled. The feed slurry is introduced through an inlet feed tube into the scroll feed zone where it is accelerated and directed into the spinning bowl of the decanter centrifuge. The solids which have a higher specific gravity than the liquid phase will rapidly settle out on the inner wall of the centrifuge bowl due to the intense acceleration of centrifugal force over 3,000 x “gravity” leaving a clear inner ring liquid phase. The liquid phase flows in a helical channel between the scroll flights moving toward the large diameter end of the centrifuge bowl where the clarified liquid is expelled at a depth controlled by the adjustable liquid level discharge plates on the outlet diameter of the liquid end head-wall. The liquid phase or “centrate” then overflows into the liquid discharge cover and gravity drain from the machine. The compacted solid phase is discharged from the decanter centrifuge bowl by scroll which rotates at slightly different speed (differential speed) as controlled by the back-drive conveying the solids up the conical bowl section to the discharge ports. The dry solids are discharged into the solids discharge cover where a solids scrapper keeps the cover clear of solids cake build-up.

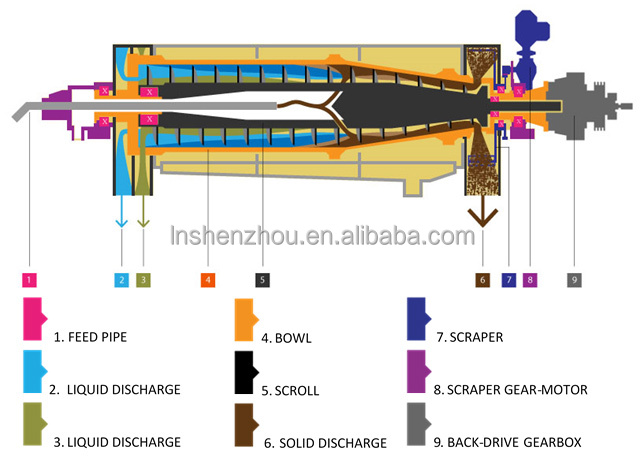

Characteristics of Three-phase Separation

SHENZHOU DRW Decanter Centrifuges allow separation between heavy liquid phase / light liquid phase and solid phases contained within a feed-slurry of industrial or municipal wastewater sludges or other industrial and/or food Applications.The feed slurry is introduced through an inlet feed tube into the scroll feed zone where it is accelerated and directed into the spinning bowl of the decanter centrifuge. The solids which have a higher specific gravity than the liquid phase will rapidly settle out on the inner wall of the centrifuge bowl due to the intense acceleration of centrifugal force over 3,000 x “gravity” leaving a clear inner ring liquid phase. The liquid phase flows in a helical channel between the scroll flights moving toward the large diameter end of the centrifuge bowl where the clarified heavy liquid phase is expelled at a depth controlled by the adjustable liquid level discharge plates on the outlet diameter of the liquid end head-wall. The Light liquid phase is expelled separately from bowl through adjustable depth nozzles. Both liquid “centrate” phases then overflows into their respective liquid discharge covers and gravity drain from the machine. The compacted solid phase is discharged from the decanter centrifuge bowl by scroll which rotates at slightly different speed (differential speed) as controlled by the back-drive conveying the solids up the conical bowl section to the discharge ports. The dry solids are discharged into the solids discharge cover where a solids scrapper keeps the cover clear of solids cake build-up.

Title goes here.

Available Back-drive transmission types:

Variable speed scroll back-drive with electric drive motor and closed circuit hydraulic pump/motor

Variable speed scroll back-drive with double electric drive motors

Fixed speed back-drive with electric drive motor

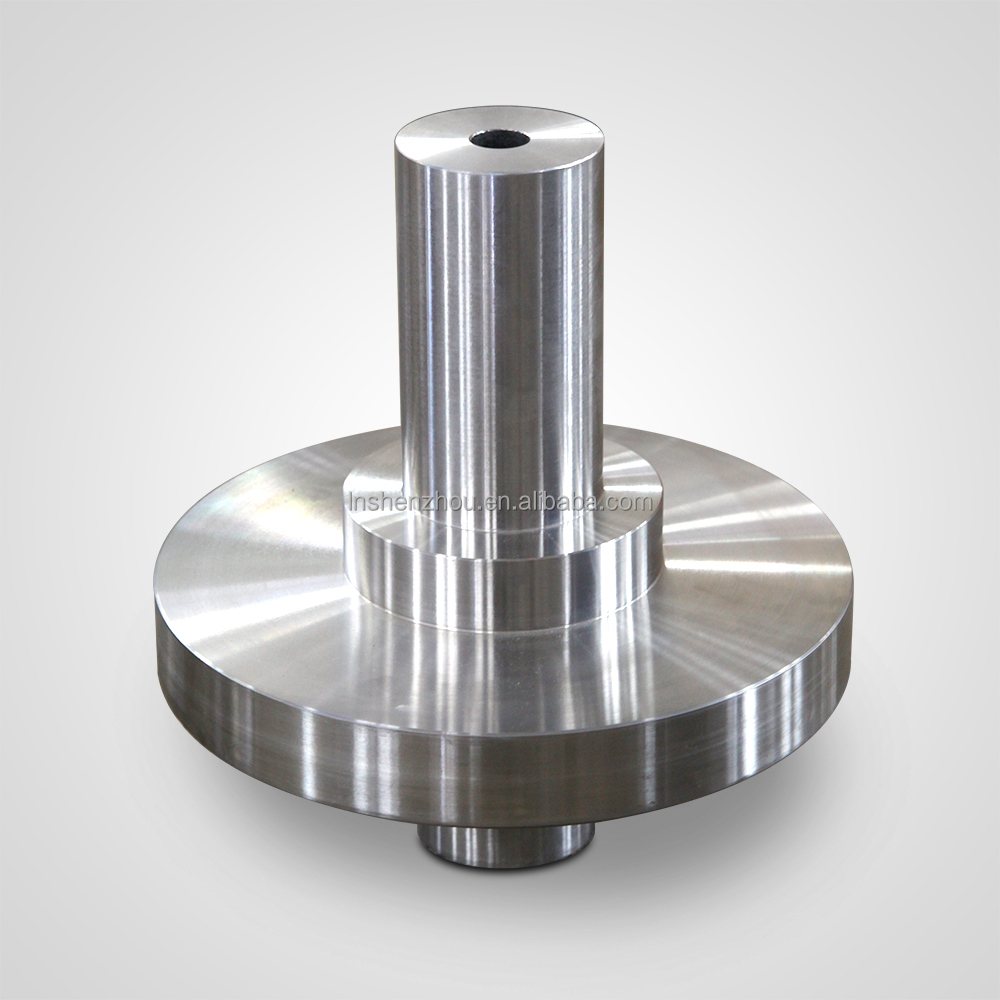

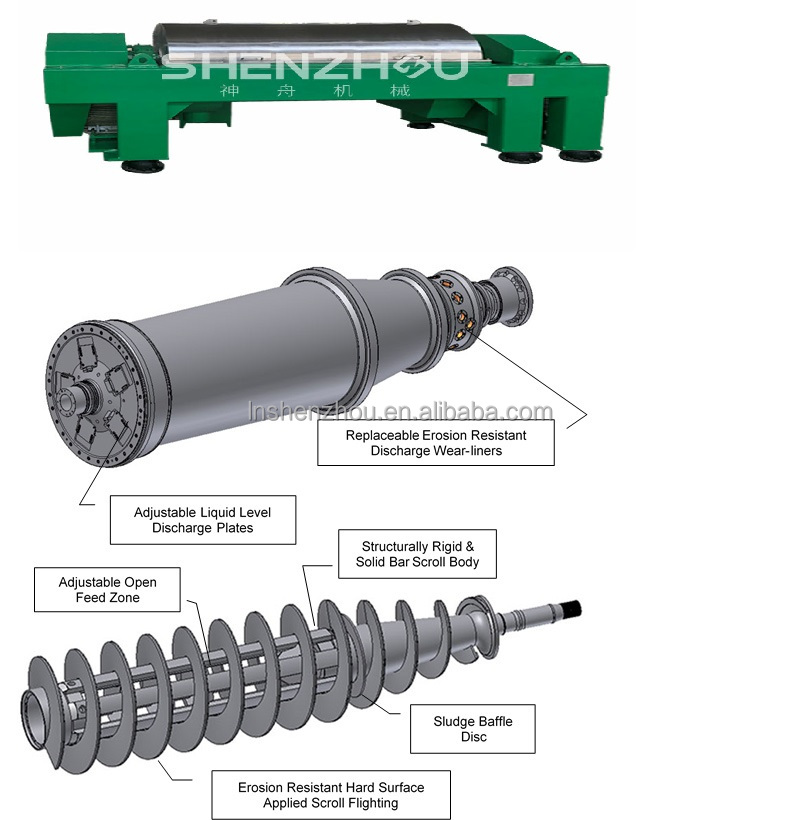

Decanter Centrifuge Bowl and Scroll Assemblies

Adjustable Liquid Level Weir Plates

All other major manufacturers make use of several different bothersome weir plates to change liquid levels. These are usually half-crest moons that are difficult to change and are often lost in storage. SHENZHOU only makes use of one plate. So, when the liquid levels do need changing the plate is exactly where you need it, on the machine. Changing the liquid levels is also easier on the SHENZHOU because of the three section hinged cover, which provided quick and easy access to the weir plate.

Replaceable Sludge Discharge Wear Bushings

The discharge bushings are very easy to replace due to our three section hinged cover and the use of standard tools. We can also rotate our discharge bushings to get more life out of them. The wear on the bushings is always on the same side, so simply rotate the bushing in place 1/4 turn to gain up to 4 times more wear life.

All other major manufacturers make use of several different bothersome weir plates to change liquid levels. These are usually half-crest moons that are difficult to change and are often lost in storage. SHENZHOU only makes use of one plate. So, when the liquid levels do need changing the plate is exactly where you need it, on the machine. Changing the liquid levels is also easier on the SHENZHOU because of the three section hinged cover, which provided quick and easy access to the weir plate.

Replaceable Sludge Discharge Wear Bushings

The discharge bushings are very easy to replace due to our three section hinged cover and the use of standard tools. We can also rotate our discharge bushings to get more life out of them. The wear on the bushings is always on the same side, so simply rotate the bushing in place 1/4 turn to gain up to 4 times more wear life.

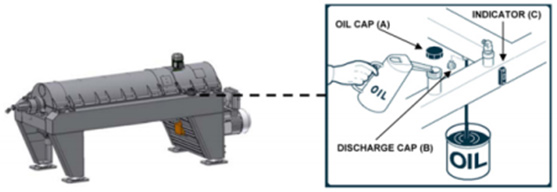

Integrated zero-footprint hydraulic back drive and Reservoir System

One of the biggest concerns we get from operators in regards to hydraulic back drives is the location and connection of the hydraulic tank. Typically a hydraulic unit is placed next to the centrifuges with the hydraulic lines running on the ground to the centrifuge. SHENZHOU has addressed this issue by simply using the legs of the centrifuge as hydraulic tank. This reduces the footprint of the complete supply, and removes any, potentially unsafe, connection lines lying around. In effect SHENZHOU offers.

One of the biggest concerns we get from operators in regards to hydraulic back drives is the location and connection of the hydraulic tank. Typically a hydraulic unit is placed next to the centrifuges with the hydraulic lines running on the ground to the centrifuge. SHENZHOU has addressed this issue by simply using the legs of the centrifuge as hydraulic tank. This reduces the footprint of the complete supply, and removes any, potentially unsafe, connection lines lying around. In effect SHENZHOU offers.

Decanter Centrifuge Machine Base Frame and Cover Assemblies

Sludge Cover Scraper Mechanism

Solids build up in the sediment sludge discharge cover is one of the major reasons that a centrifuge stalls. The SHENZHOU centrifuges are equipped with a separate internal cover scraper and continuous full geared, independently driven low-speed (5RPM) solids scraper to prevent this from happening. The solids cake discharge of a centrifuge is thrown against the internal walls of the sediment sludge discharge cover with a force over 1000xG. Normally, the sediment falls down because of gravity, but with alum sludge and other sticky sludges, the sediment build ups clogging the centrifuge solids discharge.

If the discharge is clogged, no solids can leave the centrifuge, and the bowl of the centrifuge will fill up completely, causing

the centrifuge to fault and shut down. It is then necessary to remove the scroll and clean out the bowl. In certain applications, this might require a 30 ton winch to extract the scroll from the bowl. Some other manufacturers also have a scraper but it runs with the bowl/scroll assembly, which results in excessive wear in the scraper blades and can cause increase in loss of balance.

Others may use a chain driven scraper motor resulting in sealing problems in the discharge chamber. The SHENZHOU Scraper is fully geared, uses ball bearings, and operates independently from the bowl and the scroll. This feature sets the scraper of the SHENZHOU centrifuge apart from every other major manufacturer.

Solids build up in the sediment sludge discharge cover is one of the major reasons that a centrifuge stalls. The SHENZHOU centrifuges are equipped with a separate internal cover scraper and continuous full geared, independently driven low-speed (5RPM) solids scraper to prevent this from happening. The solids cake discharge of a centrifuge is thrown against the internal walls of the sediment sludge discharge cover with a force over 1000xG. Normally, the sediment falls down because of gravity, but with alum sludge and other sticky sludges, the sediment build ups clogging the centrifuge solids discharge.

If the discharge is clogged, no solids can leave the centrifuge, and the bowl of the centrifuge will fill up completely, causing

the centrifuge to fault and shut down. It is then necessary to remove the scroll and clean out the bowl. In certain applications, this might require a 30 ton winch to extract the scroll from the bowl. Some other manufacturers also have a scraper but it runs with the bowl/scroll assembly, which results in excessive wear in the scraper blades and can cause increase in loss of balance.

Others may use a chain driven scraper motor resulting in sealing problems in the discharge chamber. The SHENZHOU Scraper is fully geared, uses ball bearings, and operates independently from the bowl and the scroll. This feature sets the scraper of the SHENZHOU centrifuge apart from every other major manufacturer.

Why Purchase a DRYCAKE DR Decanter Centrifuge?

* The centrifuge is highly automated. After startup, which is automated, the operator can walk away. Usually, an operator is only required to periodically check on the operation of the system to insure proper continued operation.

* The shutdown sequence of the centrifuge is also completely automated – just push a button. The belt press will usually require one half hour of wash down, which is time consuming and messy.

* The belt press takes up more space – the centrifuge takes up considerably less space.

* The centrifuge is totally enclosed. This eliminates odor and mess in the plant.

* Operators can be exposed to aerosols in the air due to high pressure wash of the belt. This does not occur with a centrifuge.

* The belt press uses a continuous flow of wash-water, which adds loading to the plant. The centrifuge does not.

* The centrifuge will normally provide a cake with 2% or higher cake solids than a belt press. The actual difference will depend upon the design and quality of the belt press. A lower cost belt press will produce even lower solids. This adds to hauling and disposal cost. Over 5 or 10 years, this difference can easily pay for the centrifuge.

* A belt press is lower in initial cost than a centrifuge. However, when installation costs are included, system cost will tend

to equalize.

* The price for ancillary equipment such as feed pump, polymer system, conveyors, etc. will be the same for a belt press or a centrifuge. Therefore, when the entire system, including installation, is considered, the cost differential is minimal.

* A belt press requires a special foundation. The floor under the press must be sloped to a drain with curbing all around. This adds to the installation cost.

* Why buy a skid mounted or containerized SHENZHOU DRW Decanter Centrifuge system? A skid mounted or containerized SHENZHOU DRW

Decanter Centrifuge system offers additional advantages:

* The skid mounted system has a very low installation cost since the entire equipment package is delivered completely

pre-mounted, pre-piped and pre-wired* A skid mounted or containerized SHENZHOU DRW Decanter Centrifuge system does not require a special foundation only requires a flat floor.

* The shutdown sequence of the centrifuge is also completely automated – just push a button. The belt press will usually require one half hour of wash down, which is time consuming and messy.

* The belt press takes up more space – the centrifuge takes up considerably less space.

* The centrifuge is totally enclosed. This eliminates odor and mess in the plant.

* Operators can be exposed to aerosols in the air due to high pressure wash of the belt. This does not occur with a centrifuge.

* The belt press uses a continuous flow of wash-water, which adds loading to the plant. The centrifuge does not.

* The centrifuge will normally provide a cake with 2% or higher cake solids than a belt press. The actual difference will depend upon the design and quality of the belt press. A lower cost belt press will produce even lower solids. This adds to hauling and disposal cost. Over 5 or 10 years, this difference can easily pay for the centrifuge.

* A belt press is lower in initial cost than a centrifuge. However, when installation costs are included, system cost will tend

to equalize.

* The price for ancillary equipment such as feed pump, polymer system, conveyors, etc. will be the same for a belt press or a centrifuge. Therefore, when the entire system, including installation, is considered, the cost differential is minimal.

* A belt press requires a special foundation. The floor under the press must be sloped to a drain with curbing all around. This adds to the installation cost.

* Why buy a skid mounted or containerized SHENZHOU DRW Decanter Centrifuge system? A skid mounted or containerized SHENZHOU DRW

Decanter Centrifuge system offers additional advantages:

* The skid mounted system has a very low installation cost since the entire equipment package is delivered completely

pre-mounted, pre-piped and pre-wired* A skid mounted or containerized SHENZHOU DRW Decanter Centrifuge system does not require a special foundation only requires a flat floor.

* All components are tested in the factory before shipment to insure proper operation. This greatly reduces startup time and cost.

Packing & Delivery

wooden case

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap