China Decanter Centrifuge Manufacturer manufacturers - Shenzhou

We are Manufacturer, Supplier, Wholesaler, Trader of Decanter Centrifuges, Decanter Centrifuge For Sludge Dewatering, Vertical Decanter Centrifuges, Centrifuges, Decanter and Separation Equipments for Waste Water Treatment, Food and Beverages, Oil Extraction.

The extensive utilization of Shenzhou starch centrifuges in wheat starch production technology significantly enhances the operational efficiency of starch facilities while concurrently decreasing production expenses.Shenzhou starch centrifuges find application in wheat starch production for tasks such as wheat flour separation, protein extraction,and wheat starch dewatering.

Shenzhou Separation Decanters For Protein Production Process

Products Description

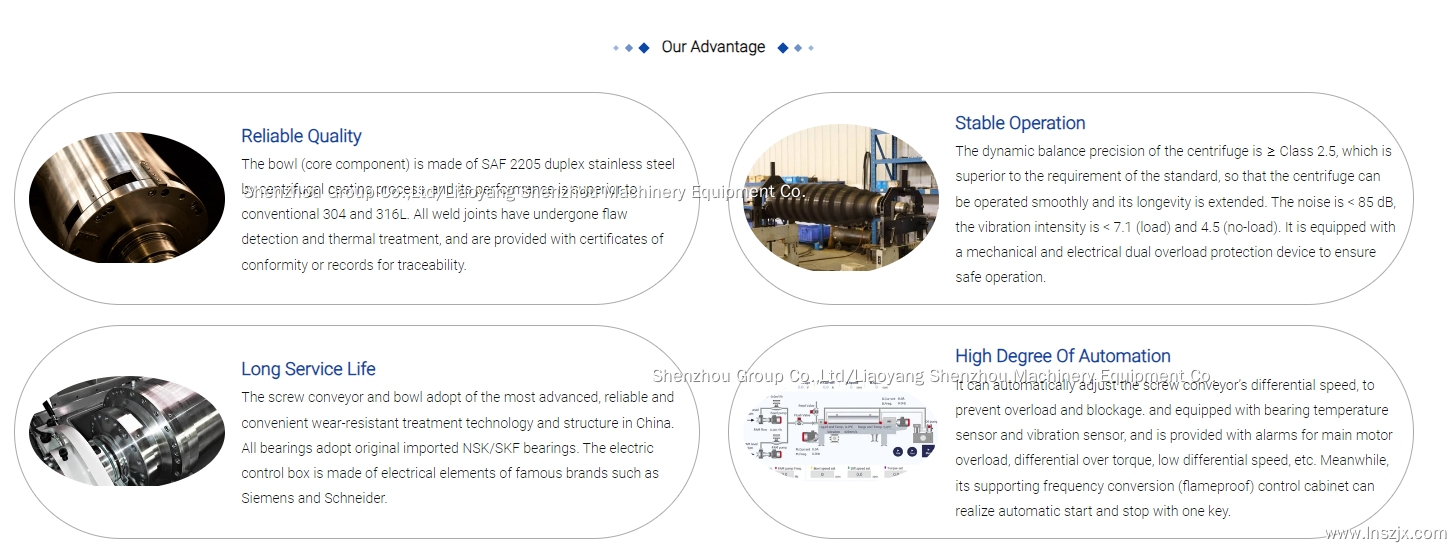

The centrifugal separator stands as a pivotal apparatus in wheat starch production. Within the starch separation procedure, the Shenzhou starch centrifuge occupies merely 1% of the space needed by conventional sedimentation flow tanks, resulting in substantial cost savings in construction investment. The entire starch separation and extraction process unfolds in a continuous, enclosed system, significantly enhancing starch yield and quality. Furthermore, our centrifuge offers high capacity, low energy consumption, and exceptional reliability. We can also furnish tailored technical solutions aligned with your specific production requirements.

Drive Type:VFD + PLC + HMI

Bowl Material: SUS2205(Duplex Stainless Steel) / SUS2304 (Duplex Stainless Steel) / 316L / 316 Centrifugal Casting

Screw Material: SUS2205(Duplex Stainless Steel) / SUS2304 (Duplex Stainless Steel) / 316L / 316 Centrifugal Casting

Bearing:SKF / NSK

Wheat Starch Extraction Process

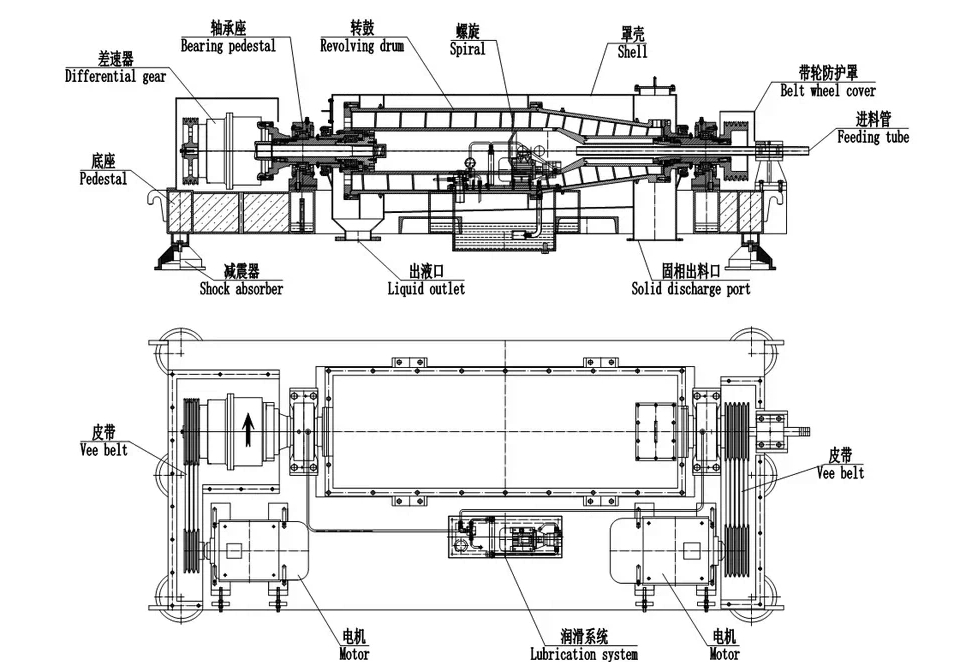

The working principle of a wheat starch decanter centrifuge is based on the principles of centrifugal force and differential sedimentation. During operation, the slurry containing wheat starch is introduced into the centrifuge through a feed inlet. As the slurry enters the centrifuge, it is subjected to high-speed rotation,Under the influence of centrifugal force, the heavier components, which in this case include the wheat starch granules, are forced outward toward the inner wall of the centrifuge drum. Simultaneously, the lighter components, such as water and impurities, move toward the center of the drum.

The separated wheat starch is continuously discharged from one end of the drum, while the liquid phase containing water and impurities is expelled from the other end. This separation process is highly efficient and occurs continuously, ensuring a consistent output of high-quality wheat starch.

The primary function of the wheat starch decanter centrifuge is to separate the starch from other components in the slurry, including water and impurities. This process significantly improves the yield and quality of wheat starch, making it a crucial piece of equipment in wheat starch production.

Why Choose Shenzhou Decanter Centrifuge

Application Field

Wastewater treatment,

Mud/sudge treatmengt,

Separation of PVC/crystal and DCD,

Tire powder/magnetic material dewatering,

Tilo2/Kaolin clay/Diatomile/cretaceous/carbon white and carbon black classification,

Fruit and vegetable juice/ beer clarification

Protein/kitchen waste separation

Starch/distiller's grain dewatering

Herbal dehydration

Hot Tags: wheat starch extraction, China wheat starch extraction manufacturers, suppliers, factory, dewatering of minerals, large scale industrial centrifuge, automatic centrifuge, drilling mud degasser, clarification process in palm oil mill, phytoplankton

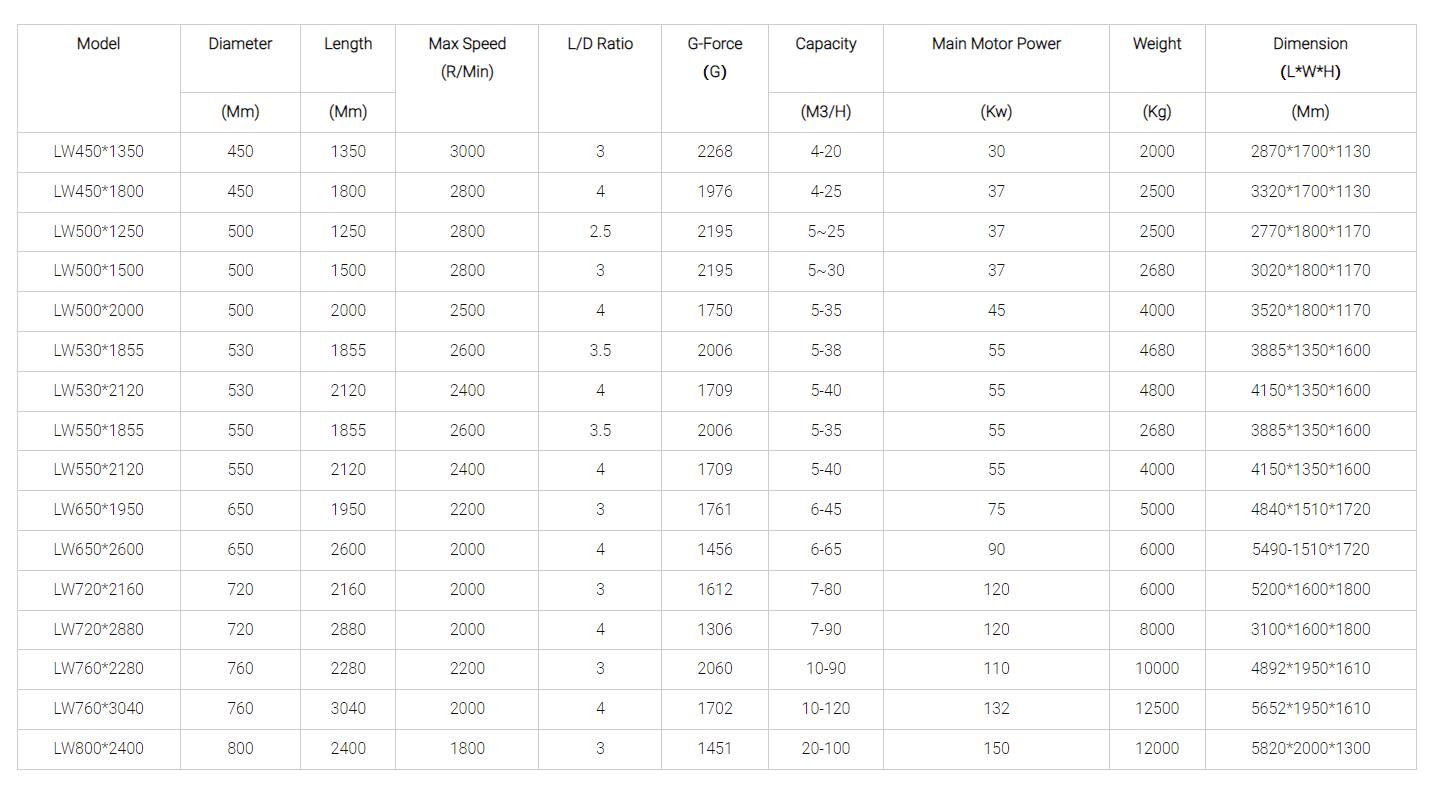

Technical Parameter:

Main Choices

According to user's requirement, the product contact parts can be made of austenite stainless (321, 316L….), Haynes alloy, titanic alloy or other anti-erosion materials.

Customers visited Shenzhou Group from other countries: