Automatic Separating Disc Centrifuge for Marine Algae/Seaweed Extraction

Algae Industry

With the fast growth of the population and industrialization demand for food and various raw materials is increasing constantly. R&D studies on production of a number of raw materials is gaining speed for the sake of satisfying the demand as a result of its continuous increase. In the result of the studies that are carried out "Microalgae" have become a significant raw material source for a number of industries.

Algae are marine creatures which can survive and grow in many other environments. It is a very important raw material used in feeding of marine animals such as shrimp, fish larvae, rotifer. It is extensively used for production of marine animal feed production and as soil enriching fertilizer in agriculture. It is also used in energy, chemistry, cosmetics, pharmaceutical chemistry, waste treatment, tooth care and alcohol industry.

Due to fast development of agriculture and fast increase in production demand, yield of agricultural areas is desired to be at utmost level. Microalgae improve the soil quality and fertility significantly.

Customer Benefits

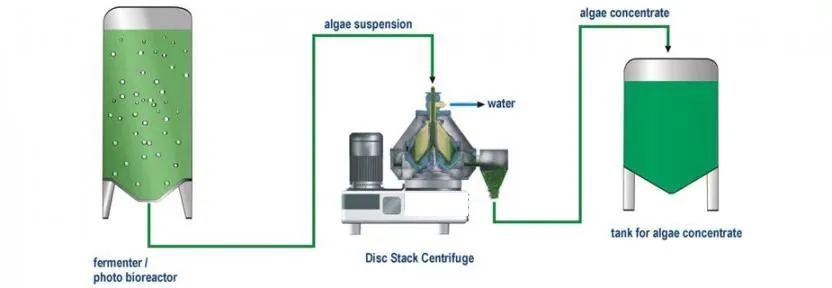

Algae harvesting with the Shenzhou Separator

The algae suspension flows from the photobioreactor directly into the Shenzhou Separator. Then the distributor gently accelerates the suspension to full speed. Due to the high centrifugal force of up to 12,000 g, the separator dewaters the algae suspension producing an algae concentrate with creamy consistency. Thus making the algae concentrate ideal for further processing. Small to medium-sized plant benefit in particular from the low investment and low operating costs of the single-stage process.

up to 25 percent lower investment costs

lower costs for further processing or drying due to a very high-quality algae concentrate

suitable for medium and small businesses

Algae concentrate after processing with the separator

Centrifuge machine Standard design

The machine consists of a frame that has a horizontal drive shaft with clutch and brake, worm gear , lubricating oil bath and vertical bowl spindle in the lower part.

The bowl is mounted on top of the spindle in the lower part. The bowl is mounted on top of the spindle , inside the space formed by the upper parts of the frame , the ring solid cover, the collecting cover, and frame hood . The feed and liquid discharge system , including the paring disc pump for the heavy phase, also rests on this structure. All parts in contact with the process liquid are made of stainless steel. The bowl is of the solid-ejecting disc type with hydraulic operating system. The electric motor is of the variable frequency drive type or of controlled-torque type.

Basic equipment

Concentrator or purifier parts, inlet and outlet devices, revolution counter, set of erosion-protective parts ,illuminated sight glass box for light phase outlet , vibration switch , vibration-isolating base plate , flange motor, set of tool and standard set of spare.

Optional extras

Started equipment, frequency converter, discharge control panel, standard set of fittings, set of CIP valves and fittings and serviceability package for online viewing of separator status

Centrifuge machine Main Parameter:

Model | Bowl Speed(rpm) | Capacity(Per Hour) | Running Load(Watts) | Dimensions, Overall (mm) | ||

Width | Front-to-Back | Height | ||||

250 | 8500 | 500-800 | 4.0 | 850 | 850 | 1200 |

270 | 7300 | 1000 | 4.0 | 950 | 950 | 1200 |

300 | 7150 | 1500 | 5.5 | 1025 | 1300 | 1300 |

360 | 7056 | 2000-3000 | 7.5 | 1500 | 1100 | 1500 |

400 | 7038 | 3000 | 7.5 | 1500 | 1100 | 1550 |

500 | 6600 | 5000-8000 | 15.5 | 1772 | 1500 | 1855 |

550 | 6200 | 8000-15000 | 18.5 | 1970 | 1560 | 1970 |

730 | 4900 | 50000-80000 | 55.0 | 2580 | 1980 | 2340 |

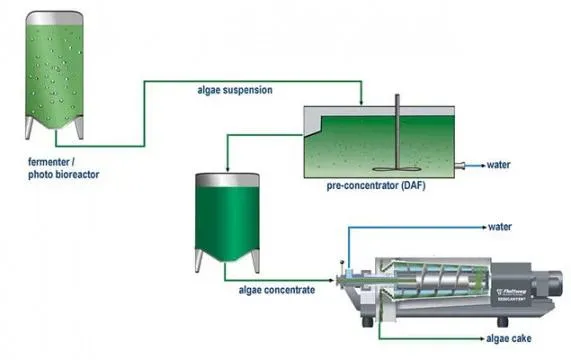

Algae harvesting with the Decanter centrifuge

Algae harvesting with the decanter centrifuge is a two-stage process that is ideal for larger operations: The algae suspension from the photobioreactor is initially pre-concentrated. The algae concentrate then flows on into the Shenzhou decanter centrifuge, where the cell harvesting takes place. The decanter centrifuge dewaters the algae concentrate to a compact cake with 22 to 25 percent dry substance content. Only this special decanter centrifuge is capable of thickening the fine and soft algae cells in such an efficient way.

The pre-concentration in the two-stage process saves energy when compared with single-stage processes. The more water that is separated beforehand, the less the centrifuge has to separate.

up to 60 percent lower operating costs (e.g. energy)

up to 25 percent lower investment costs

22 to 25 percent high dry solids content for optimum further processing

Application :

discharge, suitable for pastoral herdsmen's home use ; large separators for industrial production, electric drive, automatic or artifical discharge.

Mineral oil separator: for fuel oil, diesel oil, lubricating oil and transformers oil etc similar emulsion,remove mechanical

impurities and water.

Vegetable oil separator: for vegetable oil refining.

Animal oil separator: for refining animal fat in meat processing, or for fish oil concentration and separation processing.

Yeast separator: for concentrated yeast, nozzle discharge.

Starch separator: for removing protein in the starch and concentrating starch, nozzle discharge.

Lanolin separator:in wool industry for extracting lanolin,nozzle discharge.

Pharmaceutical disc separator: for the extraction of antibiotics, vitamins in the pharmaceutical industry;also for separating

liquid-solid three-phase mixture in the pharmaceutical and chemical industry.

Beer separator: for beer, malt juice and other beverages clarification.

Latex separator: for concentrating rubber latex and out of impurities.

Paint separator: for separating impurities in the coating, to improve the quality of the coating.