Key Factors for Selection of Tubular Centrifuges

Basic Parameters of Solid-Liquid Two-Phase System

Solid Concentration: Tubular centrifuges are only suitable for dilute slurries with solid volume concentration <1%. Excessively high concentration will lead to rapid sediment accumulation on the inner wall of the drum, frequent shutdowns for cleaning, and significant efficiency reduction.

Solid Particle Size: It is suitable for ultra-fine particles (0.1–10 μm), especially for colloidal material separation. The smaller the particle size, the higher the separation factor of the selected model (e.g., a separation factor of ≥30,000 G is recommended for particles <1 μm).

Solid-Liquid Density Difference: Density difference is the driving force for centrifugal sedimentation. The smaller the density difference (e.g., close to 100 kg/m³), the higher the required separation factor and the longer the material residence time, which can be achieved by increasing the drum length-diameter ratio (4–8 is recommended).

Material Corrosiveness and Abrasiveness

Corrosive Working Conditions (e.g., acidic leaching solution, cyanide-containing solution in mines): For drum materials, titanium alloy (TA2/TA10) or Hastelloy C276 is preferred for excellent resistance to strong acids and alkalis; stainless steel 316L is applicable for ordinary neutral materials.

Abrasive Working Conditions (containing a small amount of hard fine particles): The inner wall of the drum shall be coated with tungsten carbide wear-resistant coating to avoid equipment abrasion caused by particle scouring under high-speed rotation.

Material Viscosity and Temperature

When viscosity >50 mPa·s, the particle sedimentation resistance increases. It is necessary to increase the drum speed or reduce the feed flow rate; for high-temperature materials (>100℃), high-temperature-resistant seals and drive systems shall be selected to prevent equipment deformation or seal failure.

II. Process Requirements (Goal-Oriented Factors)

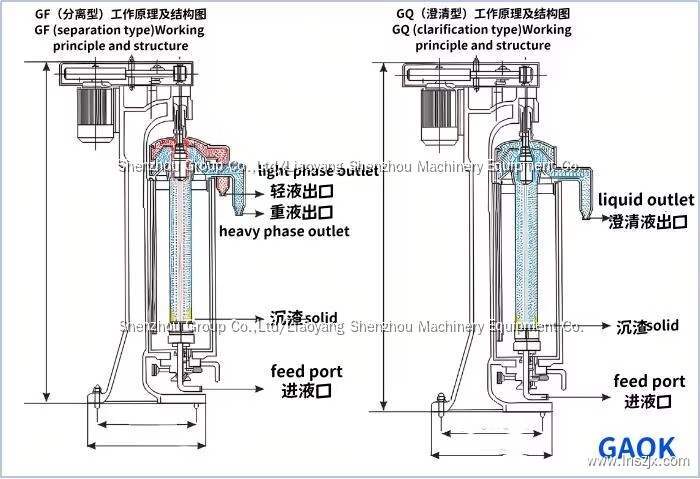

Separation Goals and Indicators

If the goal is liquid clarification (e.g., purification of gold mine leaching solution), attention shall be paid to filtrate clarity (requiring filtrate solid content <50 ppm). High-separation-factor models are preferred, combined with a reasonable overflow port structure.

If the goal is solid enrichment and recovery (e.g., recovery of fine particles of rare metals), attention shall be paid to solid recovery rate. It is necessary to control the drum speed and feed rate to ensure sufficient particle sedimentation time.

Processing Capacity Requirements

The single-unit processing capacity of tubular centrifuges is relatively small (usually 0.5–5 m³/h). For processes requiring large flow rates, multi-unit parallel operation or pre-concentration equipment (e.g., microfiltration machine) can be adopted to reduce solid concentration before treatment.

Processing capacity is positively correlated with drum diameter. The larger the diameter (e.g., 150 mm), the higher the processing capacity, but the separation factor will decrease accordingly. A balance between the two shall be achieved.

Operation Mode Requirements

Batch Operation: Manual slag discharge models are low-cost, suitable for small-batch, low-frequency treatment scenarios.

Semi-Continuous Operation: Select automatic slag discharge models (e.g., nozzle type, piston pusher type). Regular slag discharge reduces downtime, suitable for medium-scale continuous processes, but the equipment cost will increase by 30%–50%.

III. Operating Conditions (On-Site Adaptation Factors)

Installation Environment

Space Limitations: Tubular centrifuges are vertical structures with a small footprint, but installation height (usually 2–4 m for the whole machine) and pipeline layout space for top discharge shall be considered.

Explosion-Proof Requirements: For underground mines or scenarios with flammable and explosive gases, Ex d ⅡC T4 explosion-proof drive motors and electrical control systems shall be selected to comply with explosion-proof safety specifications.

Compatibility of Supporting Systems

Feed System: A variable-frequency feed pump shall be configured to stably control the feed flow rate and avoid insufficient material residence time in the drum due to excessive flow rate.

Auxiliary Systems: For high-temperature materials, a cooling system shall be equipped; for corrosive materials, an acid-base neutralization device shall be equipped to ensure safe equipment operation.

IV. Economic and Operation & Maintenance Factors

Equipment Cost and Return on Investment

The higher the separation factor, the more special the material (e.g., titanium alloy), and the higher the automation level, the higher the equipment procurement cost. It is necessary to calculate the investment payback period (usually recommended ≤2 years) based on solid recovery value or liquid purification benefits.

Operation & Maintenance Cost

The operation and maintenance cost of manual slag discharge models mainly lies in manual cleaning man-hours and replacement of wearing parts (e.g., seals).

For automatic slag discharge models, the cost of nozzle/piston wear and replacement and the maintenance cost of the variable-frequency control system shall be considered.

Spare Parts and After-Sales Service

Prioritize brands with sufficient supply of wearing parts (e.g., sealing rings, wear-resistant coatings).

Consider the manufacturer's on-site installation and commissioning and after-sales maintenance response speed, especially for remote mine scenarios.

Priority Ranking of Selection Decisions

Material properties (concentration, particle size, corrosiveness) > Process separation indicators > Processing capacity and operation mode > On-site installation conditions > Economy