Lws355-1400 China Industrial Centrifuge Price 3 Phase Decanter Tricanter Centrifuge for Crude Olive Oil

LWS355-1400 China industrial centrifuge price 3 Phase Decanter Tricanter centrifuge for Crude Olive Oil

Palm oil is one of the two most important vegetable oils in the world's oil and fats market. Whatever the step in the palm oilmilling process (clarification, POME, fertilizer, composting, biogas), a solid/liquid separation phase is needed to meet therequirements applying to the final product. The Shenzhou decanter centrifuge is the right solution to meet the separation needs (two and three phases) of palm oil producers and users.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Tricanter centrifuge

![Lws355-1400 China Industrial Centrifuge Price 3 Phase Decanter Tricanter Centrifuge for Crude Olive Oil]()

![Lws355-1400 China Industrial Centrifuge Price 3 Phase Decanter Tricanter Centrifuge for Crude Olive Oil]()

China 3 Phase Crude Palm oil Olive Oil Decanter tricanter centrifuge separator Centrifuge

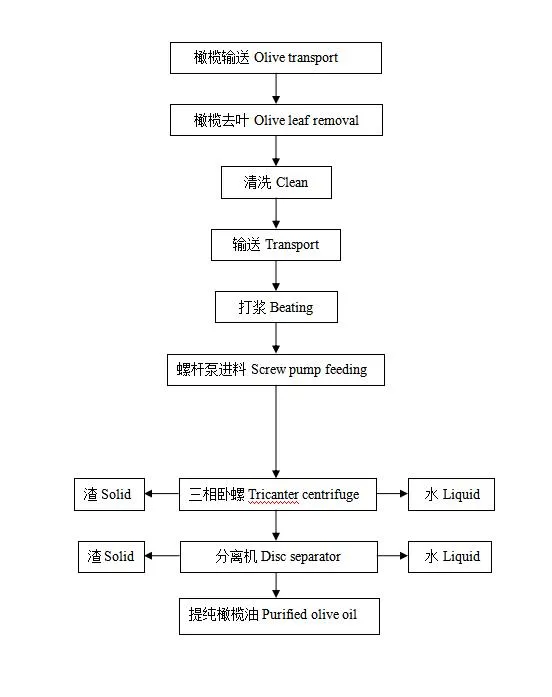

In the olive oil extraction process, low energy consumption, high quality, and automated production equipment will significantly reduce olive oil production enterprises' costs. The SHENZHOU olive oil centrifuge is a food-grade separation device specially developed for olive oil extraction. The equipment can be automatically operated continuously and has a long service life, and the maintenance cost is low. The extracted and separated oil is of first-class quality.

In the olive oil extraction process, low energy consumption, high quality, and automated production equipment will significantly reduce olive oil production enterprises' costs. The SHENZHOU olive oil centrifuge is a food-grade separation device specially developed for olive oil extraction. The equipment can be automatically operated continuously and has a long service life, and the maintenance cost is low. The extracted and separated oil is of first-class quality.

China 3 Phase Crude Palm oil Olive Oil Decanter tricanter centrifuge separator Centrifuge Details

China 3 Phase Crude Palm oil Olive Oil Decanter tricanter centrifuge separator Centrifuge

Decanter centrifuges process characteristics

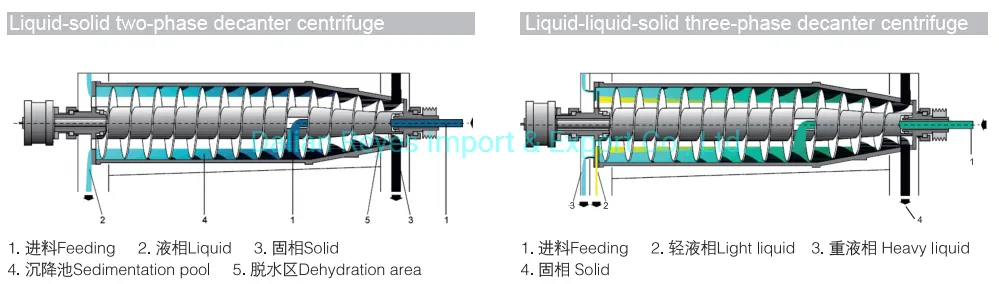

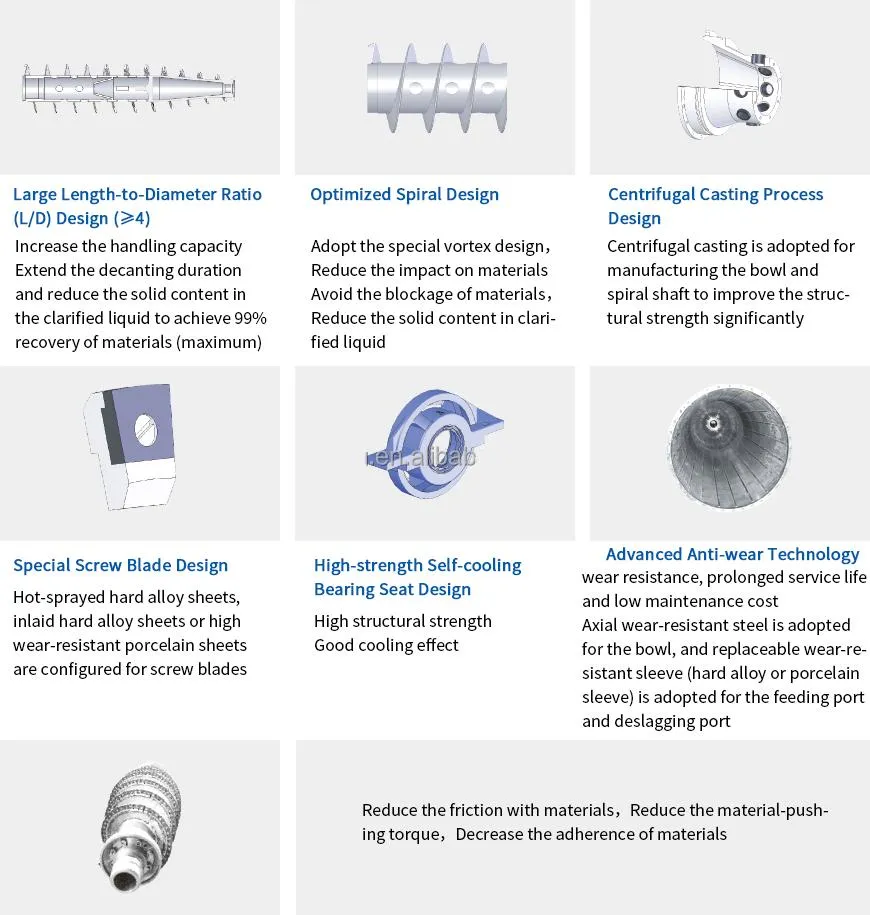

The separation process in a decanter centrifuge relies on a few process characteristics such as centrifugal force or G-force,sedimentation rate and separating factor, differential speed between the conveyor and bowl, and clarity of the liquid

discharge.Decanter centrifuges require a centrifugal force for the separation of the solids from the liquid. This characteristic is dependent on the radius of the centrifuge and its angular rotational speed. A decanter centrifuge applies a force equivalent to several thousand G's, which reduces the settling time of the particles. It is also favored to maintain a large G-force, which wil result in an improved separation.The rate at which sedimentation occurs is an important characteristic of the decanter centrifuge separation process. The sedimentation rate is influenced by the particle size, the shapes of the particles, their differential densities and the viscosity between the particles and the liquid. This process characteristic can be improved by utilizing flocculating agents. The sedimentation rate is also dependent on the separating factor of the decanter centrifuge, which is related to the centrifugal force.The exterior bowl and the scroll conveyor rotate at different high speeds. This differential speed between the two is accountable for the sedimentation throughout the decanter centrifuge cylinder. A high differential speed results in a smaller residence time of the cake settlement, so it is necessary to keep the cake thickness to a minimum to avoid impairing the discharge quality.

Keeping the cake thickness to a minimum also aids in the improvement of the cake dewatering process. For this reason, it is necessary to obtain an optimal differential speed to balance the cake thickness and quality.The characteristic above all affects the clarity of the liquid output which is dependent on the volumetric throughout rate, where a higher flow rate will result in a poor liquid clarity. Another characteristic that influences the clarity of the liquid output is the differential speed. A low differential speed results in a better clarity, therefore, aiding in the separation process. The G-Force also plays a role in the clarity of the liquid discharge. Higher G-force results in an increase in the separation of the solid particles from the liquid and yields a better clarity.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap