Shenzhou - decanters for Oil Sludge Treatment Process Centrifuge & Separator

Thanks to the efforts of our staff, we have successfully broken the barriers in technology innovation and upgrades. We have mastered technologies, which ensures the whole manufacturing process is efficient.It covers a wide application range and has found its great use in the field(s) of Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge up till now.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd is a preferred manufacturer in the Separation Equipment industry. Innovation is at the core of the value that we deliver to our customers. Our range of Separation Equipment are made with the best ingredient. Since our inception, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd have been striving forward with the aim of being a leading company in the globe. We will focus more on improving our R&D capabilities and upgrading technologies in order to develop more creative products, therefore leading the industry trends and keeping us competitive in the market.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 1050 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training |

Product Description

Oil Sludge Treatment

Through the treatment of sludge, a large amount of oil and water can be recovered, which promotes environmental protection and promotes energy reuse. The sludge centrifuge is essential equipment in this link. It can recover about 80-90% of the oil, the coherence degree of the residue can reach 40-60%, and the total volume can be reduced by more than 80% compared with before separation.Operating principle:

The purpose of separation is to separate out substances with different mass ratios from mixed fluid.Separation forms included solid-liquid separation,liquid-liquid separation and liquid-liquid-solid separation.

When mixed fluid enters rotating bowl of centrifuge through feed tube ,solids with larger density would rapidly deposit on inner wall of the bowl,forced by centrifugal acceleration.Then spiral pusher pushed deposited solids to taper end of the bowl,and discharges them out of centrifuge from residual outlet.Meanwhile ,liquid phase with smaller density forms a liquid ring layer and discharges from bowl through overflow port,the bowl and spiral pusher run at a high speed simultaneously ,for there exists speed discrepancy,deposited solids on the wall of bowl could be conveyed to residue outlet by spiral pusher.This separation process carry out continuously.

Separation technique:

Feeding-gravitational separation-liquid discharge-sediment discharge.

Separation effect factors Centrifuging factor ,length to diameter ratio of cavity ,depth of fluid pool.

Field control:

Bowl rotating speed ,rotative speed difference,between,spiral pusher and bowl depth of liquid pool.

Through the treatment of sludge, a large amount of oil and water can be recovered, which promotes environmental protection and promotes energy reuse. The sludge centrifuge is essential equipment in this link. It can recover about 80-90% of the oil, the coherence degree of the residue can reach 40-60%, and the total volume can be reduced by more than 80% compared with before separation.Operating principle:

The purpose of separation is to separate out substances with different mass ratios from mixed fluid.Separation forms included solid-liquid separation,liquid-liquid separation and liquid-liquid-solid separation.

When mixed fluid enters rotating bowl of centrifuge through feed tube ,solids with larger density would rapidly deposit on inner wall of the bowl,forced by centrifugal acceleration.Then spiral pusher pushed deposited solids to taper end of the bowl,and discharges them out of centrifuge from residual outlet.Meanwhile ,liquid phase with smaller density forms a liquid ring layer and discharges from bowl through overflow port,the bowl and spiral pusher run at a high speed simultaneously ,for there exists speed discrepancy,deposited solids on the wall of bowl could be conveyed to residue outlet by spiral pusher.This separation process carry out continuously.

Separation technique:

Feeding-gravitational separation-liquid discharge-sediment discharge.

Separation effect factors Centrifuging factor ,length to diameter ratio of cavity ,depth of fluid pool.

Field control:

Bowl rotating speed ,rotative speed difference,between,spiral pusher and bowl depth of liquid pool.

Scope of application:

SZ SEPARATION Decanters for Oil Sludge Treatment Process:

SZ Oil Sludge Decanter Equipment can effectively separate the oil, water, and solid components of the oily sludge mixture. It provides the best solution for oil slick sludge treatment. After collecting the oily (waste) water by steam heating, add suitable demulsifiers, active agents, etc. The oily water in the emulsified state can be demulsified, and the oily (waste) water after demulsification uses high-efficiency three-phase centrifuge. The machine carries out a three-phase continuous separation of oil + water + slag. The centrifuge separated water and the unlayered oil-water mixture are directly sent to the sewage treatment system for treatment. The dehydrated slag phase can be recovered by combustion or thermal desorption process. Residual crude oil, the separated oil, can be collected and used as crude oil..

SZ Oil Sludge Decanter Equipment can effectively separate the oil, water, and solid components of the oily sludge mixture. It provides the best solution for oil slick sludge treatment. After collecting the oily (waste) water by steam heating, add suitable demulsifiers, active agents, etc. The oily water in the emulsified state can be demulsified, and the oily (waste) water after demulsification uses high-efficiency three-phase centrifuge. The machine carries out a three-phase continuous separation of oil + water + slag. The centrifuge separated water and the unlayered oil-water mixture are directly sent to the sewage treatment system for treatment. The dehydrated slag phase can be recovered by combustion or thermal desorption process. Residual crude oil, the separated oil, can be collected and used as crude oil..

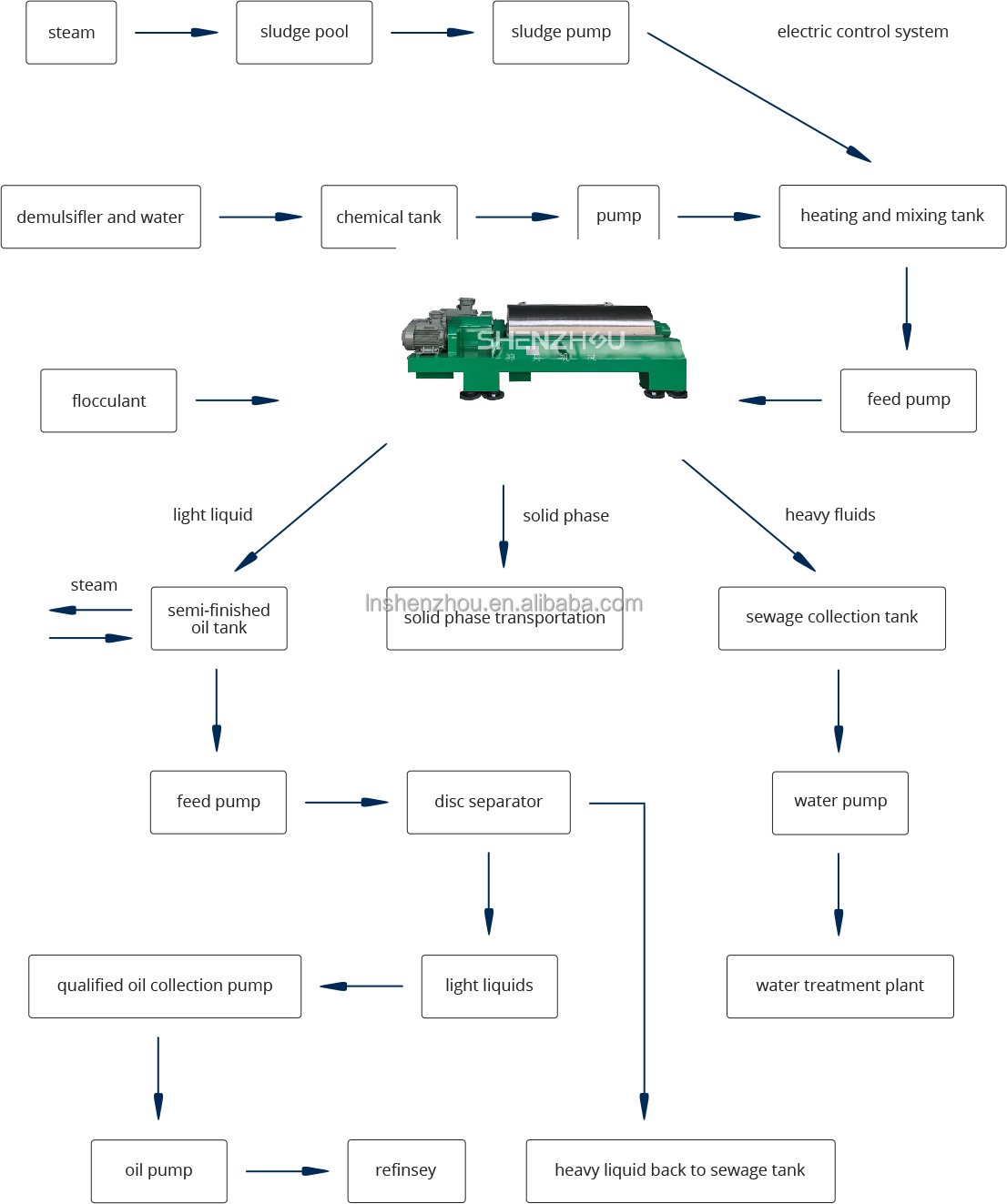

Oil Sludge Treatment Process:

1. Sludge treatment is a complete set of production process, using the principle of oxidative demulsification and centrifugalseparation. Its main equipment is composed of dosing system, feeding system, separation system, conveying system, and control system.

2. After the oily sludge is collected and heated by steam, a suitable number of additives like demulsifier and active agent are added in it, so that the oily water in the emulsified state is broken. After emulsification, a high-efficiency LWS series three-phase decanter is adopted to realize the continuous separation of oil, water, and slag in the oily sludge, and the water separated and the oil-water mixture not demulsified are directly sent to the sewage treatment system for treatment. Then, a LW series two-phase decanter with high efficiency is used for dehydration. The crude oil residue in the dehydrated slag phase can be recovered by the combustion or thermal desorption process. The separated crude oil is collected and then purified by a 3 phase disc stack separator. The purified oil can be reused.

1. Sludge treatment is a complete set of production process, using the principle of oxidative demulsification and centrifugalseparation. Its main equipment is composed of dosing system, feeding system, separation system, conveying system, and control system.

2. After the oily sludge is collected and heated by steam, a suitable number of additives like demulsifier and active agent are added in it, so that the oily water in the emulsified state is broken. After emulsification, a high-efficiency LWS series three-phase decanter is adopted to realize the continuous separation of oil, water, and slag in the oily sludge, and the water separated and the oil-water mixture not demulsified are directly sent to the sewage treatment system for treatment. Then, a LW series two-phase decanter with high efficiency is used for dehydration. The crude oil residue in the dehydrated slag phase can be recovered by the combustion or thermal desorption process. The separated crude oil is collected and then purified by a 3 phase disc stack separator. The purified oil can be reused.

Specification

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

LW550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 1300 | 7100*2000*1300 |

LWS three phase decanter parameter:

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*172 |

Main technical features

1. Industrial design

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively ease resonance during rotating of bi-rotor

When centrifuge works,there is no obvious first-order and two-order resonance regions within designed speed range,meanwhile ,whole vibration intensity of bearing seat is definited within 2mm/s-4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly eliminate phenomenon of liquid ring stalling

Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW550 and even larger models,It would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately ,our engineers have solved this problem thoroughly.

4. Unique technique adopt in main component work-blanks

The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main bearing selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

6. Constant temperature detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-change ability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.It is not only easy to maintain ,but also greatly improve the reliability and safety of equipment.

8. Simplyand safely in bearing disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high-

pressure,during disassemblement bearing from the machine.which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when disassemble bearing.

9.Main bearing lubrication system

There are two kinds of lubrication system for specific product models :

A thin oil lubrication

* Oil pump offers an uninterruptedly power to ensure oil works circularly;

* Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

* Oil filter system ensure lubricant’s cleanliness;

* Oil pressure energy storage system ensure lubrication pump offers an extra oil supply(the pressure is no less than 0.4Mpa) for 5-6 minutes,when power fails accidentally;

* Constant temperature system is available.

B grease lubrication

* Adopt a grease with properties of extreme pressure resistance ,oxidation resistance ,abrasion resistance,water scour

resistance,corrosion-proof and high temperature resistance.

* Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main bearing BH device (patent design)

There are two spare safe bearings at either end of main bearing.When machine works well,they keep certain clearance from bearing inside track to chief axis.When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately then activates emergency shutdown and goes a smooth shut down.This system protects machine free from damaging and ensure production safety.

11. GSRL feeding device (potent design)

New design of internal spiral core tube has got following achieves.Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively ease resonance during rotating of bi-rotor

When centrifuge works,there is no obvious first-order and two-order resonance regions within designed speed range,meanwhile ,whole vibration intensity of bearing seat is definited within 2mm/s-4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly eliminate phenomenon of liquid ring stalling

Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW550 and even larger models,It would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately ,our engineers have solved this problem thoroughly.

4. Unique technique adopt in main component work-blanks

The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main bearing selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

6. Constant temperature detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-change ability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.It is not only easy to maintain ,but also greatly improve the reliability and safety of equipment.

8. Simplyand safely in bearing disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high-

pressure,during disassemblement bearing from the machine.which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when disassemble bearing.

9.Main bearing lubrication system

There are two kinds of lubrication system for specific product models :

A thin oil lubrication

* Oil pump offers an uninterruptedly power to ensure oil works circularly;

* Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

* Oil filter system ensure lubricant’s cleanliness;

* Oil pressure energy storage system ensure lubrication pump offers an extra oil supply(the pressure is no less than 0.4Mpa) for 5-6 minutes,when power fails accidentally;

* Constant temperature system is available.

B grease lubrication

* Adopt a grease with properties of extreme pressure resistance ,oxidation resistance ,abrasion resistance,water scour

resistance,corrosion-proof and high temperature resistance.

* Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main bearing BH device (patent design)

There are two spare safe bearings at either end of main bearing.When machine works well,they keep certain clearance from bearing inside track to chief axis.When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately then activates emergency shutdown and goes a smooth shut down.This system protects machine free from damaging and ensure production safety.

11. GSRL feeding device (potent design)

New design of internal spiral core tube has got following achieves.Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

Production workshop

Screw production1

Screw production2:

.

High speed dynamic balance detection1

High speed dynamic balance detection2

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap