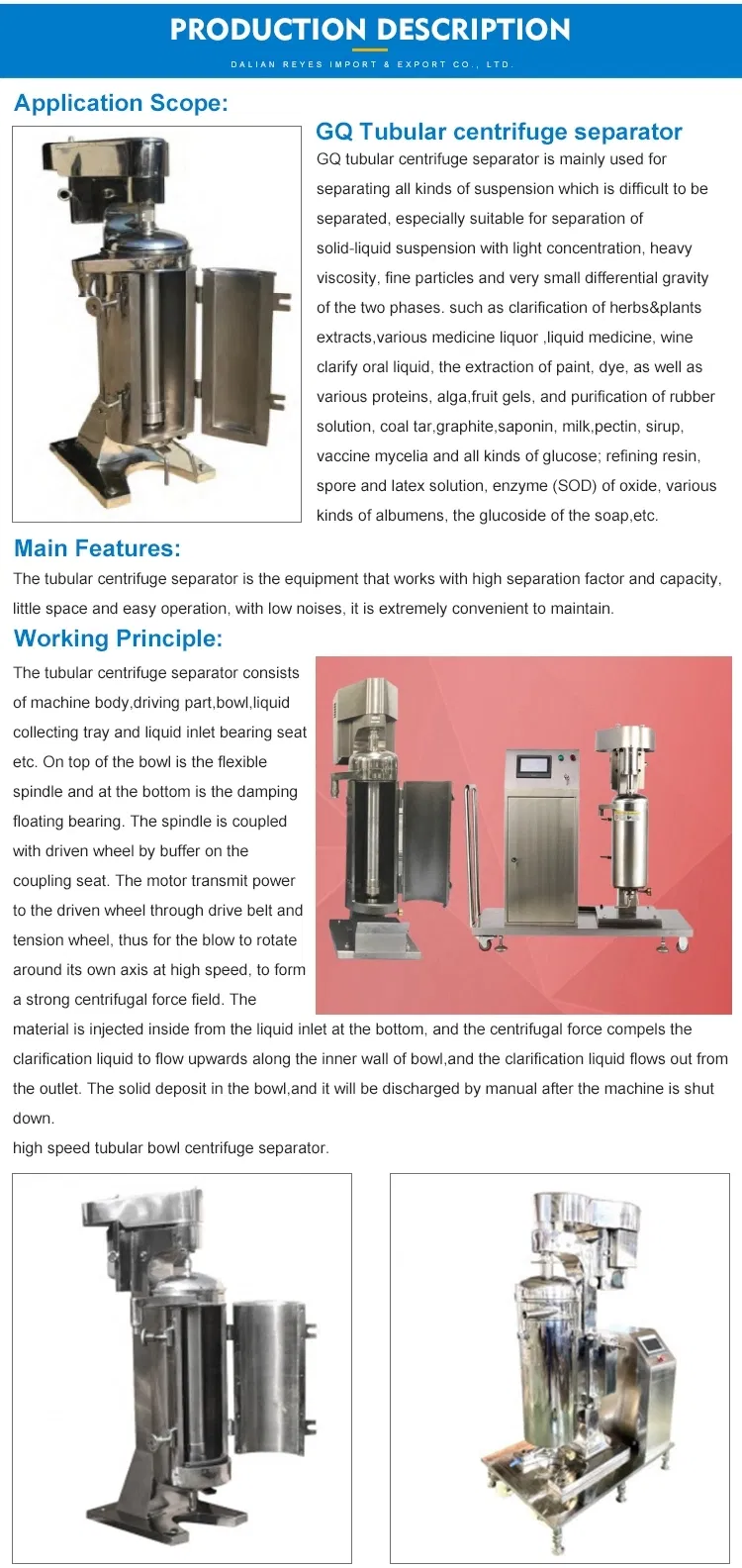

Medicine Use Industry Tubular Centrifuge Separator Manufacturer

Structure and principle: The separator consists of machine body, driving part ,bowl, liquid collecting pan and liquid-in bearing seat etc. The material is sprayed onto the bowl from the inlet on the bottom and strong centrifuge force is formed when the bowl rotates with the material and that makes the material flow upper along the wall of the bowl and then separated because of the different gravity by the centrifugal force.

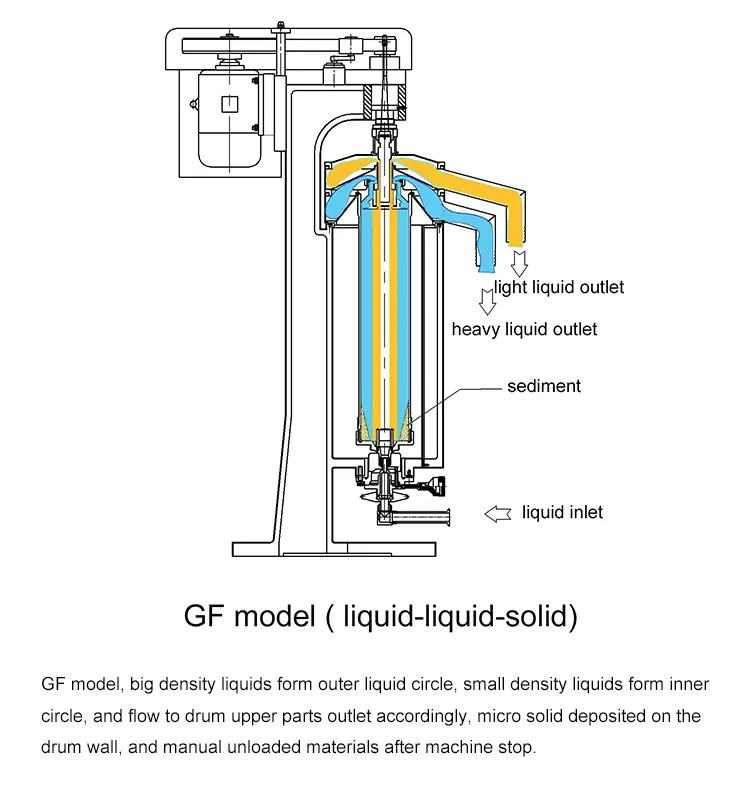

GF-for separation: Heavy liquid forms outer ring and light liquid forms inner ring. They flow to the top of the bowl and discharge from their respective outlet. And the little solid is settled on the wall of the bowl and discharged manually after the machine stops.

GQ tubular centrifuge separators are for liquid solid clarification which mainly used for clarifying all kinds of liquid mixture which content very fine solid particles, such as coffee, tea, yeast, starch , bacteria and algae and etc.

biomedicine, traditional Chinese medicine preparation, health food, beverage, chemical industry and other industries. It is an ideal equipment for centrifugal separation at present. The minimum separation particle is 1 microns, which is more suitable for extraction, concentration and clarification to liquid- solid materials with small difference in gravity and solid of small particle size and low content, strong corrosive medium and other materials.

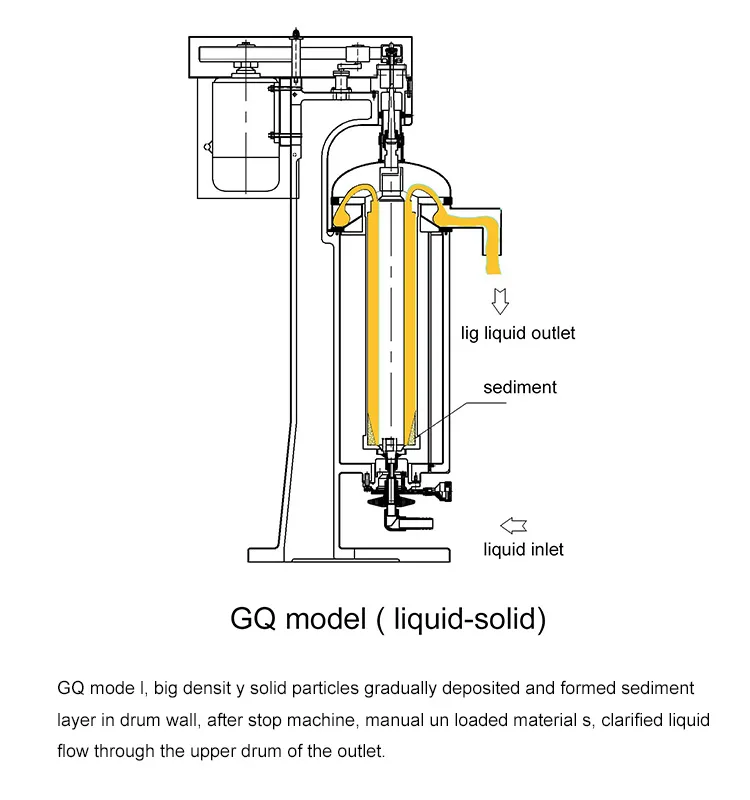

Tubular Separator is also a kind of fine separation equipment, which is suitable for the suspension with small quantity of solid, and the dissoluble liquid separation with small difference in gravity. Utilizing the centrifugal force to drive the materials of different proportion in loaded stress, thought separation can be achieved. Basic on the function of the tube separator, the tube separator is divided into two kinds of separation type, clarified tubular separator (GQ) for liquid-solid separation, and separating pipe separator (GF) for liquid (light liquid) - liquid (heavy liquid) -small amount of solid separation.

Consist of the machine cover, driving device, drum, liquid catch tray, the liquid inlet and bearing seat, this separator with high running speed, belongs to sedimentation separator. The upper drum is a flexible shaft, while the lower is damping floating bearing. The main shaft is connected by a coupling buffer and a passive wheel. Motor transmit power from the transmission belt and tension wheel to passive wheel, to drive the drum rotate around its own axis with high-speed, and thus form a strong centrifugal force field. All the materials are fed from liquid inlet under the bottom, and flow upward along the drum wall by centrifugal force fluid. During this process, the dense liquid phase forms the outer ring, and the small liquid phase forms the inner ring, which separately flow to respective liquid outlet mounted on the upper drum.

When the thickness of the sediment affect the liquid phase clarification or the capacity of the rated slag weight in the drum, the dregs of the drum wall should be removed manually after the shutdown.

Product Paramenters

Item | GQ/GF75 | GQ/GF105 | GQ/GF125 | GQ/GF150 | |||

Drum

| ID(mm) | 75 | 105 | 125 | 147 | ||

Height (mm) | 450 | 730 | 730 | 730 | |||

Sedimentation volume(L) | 2.67 | 6 | 8 | 10 | |||

Max speed(r/min) | 21000 | 17500 | 16500 | 15800 | |||

Max separation factor | 22500 | 18500 | 17300 | 16800 | |||

Inlet nozzle diameter (mm) | 3/4/6 | 4/6/8 | 6/8/10 | 8/10/12 | |||

Material inlet pressure (Mpa) | ≥0.05 | ||||||

Capacity (water capacity)L/H | 670 | 1600 | 2200 | 3200 | |||

Actually Capacity L/H(according to the solid content) | 50-80 | 100-200 | 200-300 | 300-700 | |||

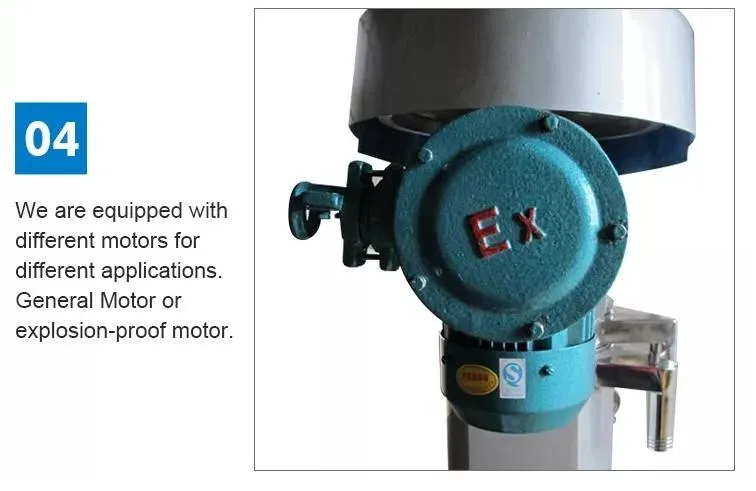

Motor model | 3 phase two pole motor | ||||||

Motor power (kw) | 1.5 | 2.2 | 3 | 3 | |||

Machine dimension (mm) | 500*700*1300 | 600*1000*1600 | 600*1000*1600 | 600*1000*1600 | |||

Machine weight (kg) | 300 | 460 | 490 | 510 | |||

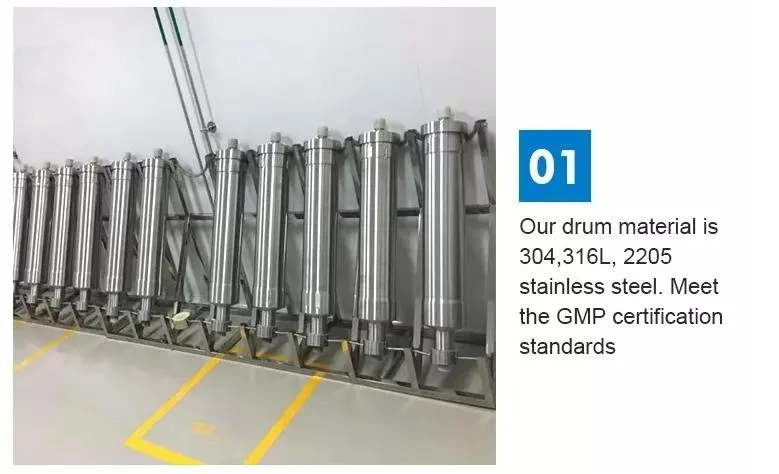

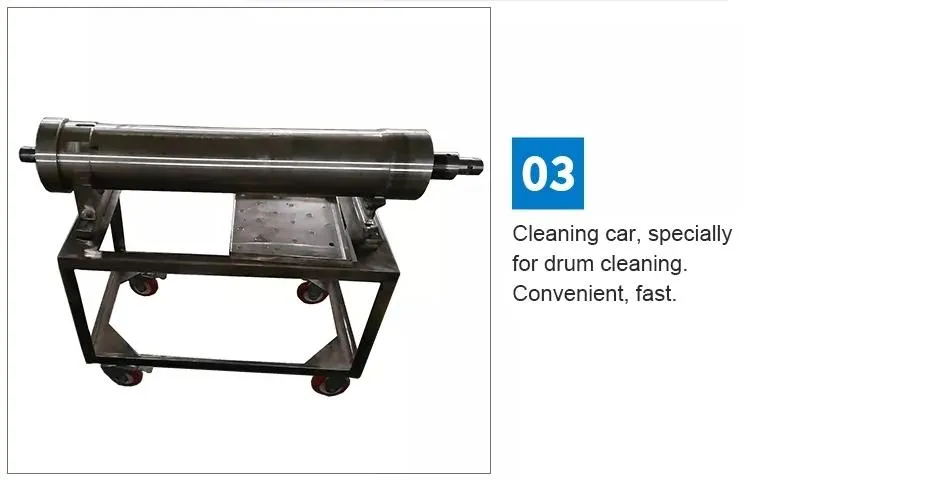

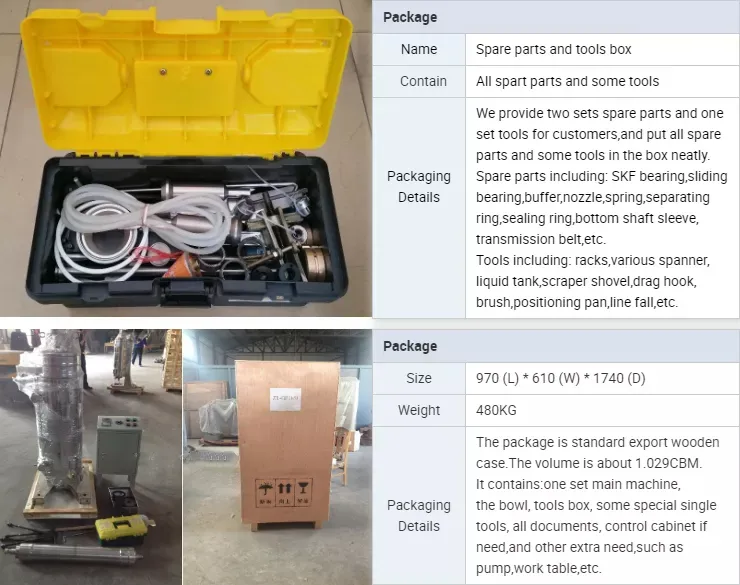

Detail

Main Characteristics

1. The unique design of interior blade is more suitable for the isolation of the fermentation bacteria than the conventional

tubular separators. Equipped with reverse stop device, the residual mother liquid can be retained completely without loss once the

machine stop.

2.With advantages of high separation factor and strong separation ability, It is applicable to separate and clarify the materials

which is difficult to separate by ordinary centrifuge and all kinds of emulsion liquid such as transformer oil, lubricating oil,

fuel oil, turbine oil, grease, dyes, and saponification separation and so on.

3.Simple structure in linear type ,easy in installation and maintation.

4.Adopting advanced world famous brand components in bearing parts, electric parts and operation parts.

5.Running in a high automatization and intellectualization,no pollution

6.Simple to set up, use and clean for minimal down-time between separations

7. No replacement membranes or costly disposables

8.3-phase electric motors provide power for rapid acceleration and quieter operation.

9.Small footprint.

Details Images