Shenzhou - horizontal centrifuge coal preparation Centrifuge & Separator

We have been continuously improving technical capabilities in manufacturing the horizontal centrifuge coal preparation since established. The product is appropriate to different uses in Separation Equipment.

5.0

Customization:

Customized logo (Min. Order: 1 Units),Customized packaging (Min. Order: 1 Units),Graphic customization (Min. Order: 1 Units)

shipping:

Support Sea freight · Land freight

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Since established, our company has focused on setting up a technology development team which aims to develop and upgrade technologies to effectively manufacture horizontal centrifuge coal preparation. It is designed to meet the industry criterion. Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd has successfully expanded its business in market in the past few years and it is very possible for the company to have a better development in the future.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 980 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training |

Product Description

Three-phase Centrifuge for Crude Oil and Coal Chemical Industry

Title goes here.

LW centrifuges are applied in various oil recovery projects. Slope oil is a valuable but dangerous resource in oilfield, in order

to mostly recover the oil, decanter centrifuge plays a key role while removing the impurity from the sludge. Apart from the slope

oil, Contaminated Lubricating Oil and engine oil needs to have water and other impurities removed on a constant basis. It’s a

reliable way to prevent symptoms of wear appearing on engine components and a drop in performance or even failures.

Oil separation and recovery

In the oil exploration activities, the oil sludge generated from pipeline rupture and the tank bottom sludge generated from tank

cleaning all contain a large amount of crude oil. In order to better protect the environment and save energy, centrifuges are

widely used to separate and recover the crude oil. WPE, after years of field trials and scientific and technological innovation,

developed a special three-phase centrifuge for recovery of crude oil, the recovery rate of crude oil as high as 85% -90%.

to mostly recover the oil, decanter centrifuge plays a key role while removing the impurity from the sludge. Apart from the slope

oil, Contaminated Lubricating Oil and engine oil needs to have water and other impurities removed on a constant basis. It’s a

reliable way to prevent symptoms of wear appearing on engine components and a drop in performance or even failures.

Oil separation and recovery

In the oil exploration activities, the oil sludge generated from pipeline rupture and the tank bottom sludge generated from tank

cleaning all contain a large amount of crude oil. In order to better protect the environment and save energy, centrifuges are

widely used to separate and recover the crude oil. WPE, after years of field trials and scientific and technological innovation,

developed a special three-phase centrifuge for recovery of crude oil, the recovery rate of crude oil as high as 85% -90%.

Process Description

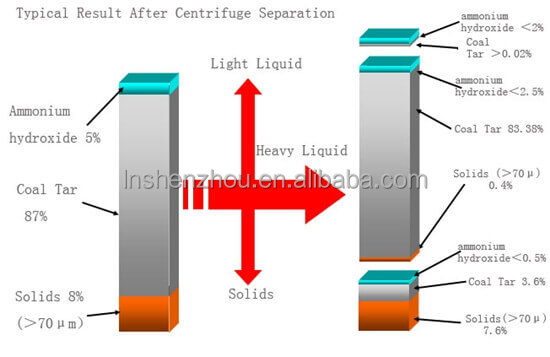

Coal tar recovery

Coal tar is a dark brown, viscous liquid produced when the coal is distilled off. The yield rate of coal tar is usually at 3-4% of the dry coal. According to different coking temperatures, coal tar can be divided into high-temperature tar, intermediate temperate and low temperature tar. According to different pyrolysis temperate, it can be divided into low temperature (450 ℃ ~ 650 ℃) dry distillation tar, low and medium temperature (600 ℃ ~ 800 ℃) furnace tar, Medium temperature (900 ℃ ~ 1000 ℃) vertical coal tar, high temperature (1000 ℃) coking tar. The crude tar is produced by the coking process with circulating ammonia spray gas and condensate cooling in the primary cooler, containing about 4% water, and sometimes up to 8 to 10%.

Coal tar is a dark brown, viscous liquid produced when the coal is distilled off. The yield rate of coal tar is usually at 3-4% of the dry coal. According to different coking temperatures, coal tar can be divided into high-temperature tar, intermediate temperate and low temperature tar. According to different pyrolysis temperate, it can be divided into low temperature (450 ℃ ~ 650 ℃) dry distillation tar, low and medium temperature (600 ℃ ~ 800 ℃) furnace tar, Medium temperature (900 ℃ ~ 1000 ℃) vertical coal tar, high temperature (1000 ℃) coking tar. The crude tar is produced by the coking process with circulating ammonia spray gas and condensate cooling in the primary cooler, containing about 4% water, and sometimes up to 8 to 10%.

Coal Tar Specifications

Type | Color | Density | Content |

Low Temperate Coal Tar | Auburnish black | Less than 1g/cm³ | Alkanes, olefins and aromatic hydrocarbons around 50%. Phenols around 30% High mechanical impurities, high metal impurities, high aromatic content |

High Temperate Coal Tar | Black | More than 1g/cm³ | It is the product of secondary decomposition of low temperature tar at high temperature, which is fundamentally different from low temperature coal tar |

LW Centrifuge has high separation efficiency, the separated particles can be as small as 2μm in diameter. The treated sludge contains more than 60% solids. It is easy to optimize the clarification of the liquid, as well as the dryness of the solid phase.

Operating principle:

The purpose of separation is to separate out substances with different mass ratios from mixed fluid.Separation forms included solid-liquid separation,liquid-liquid separation and liquid-liquid-solid separation.

When mixed fluid enters rotating bowl of centrifuge through feed tube ,solids with larger density would rapidly deposit on inner wall of the bowl,forced by centrifugal acceleration.Then spiral pusher pushed deposited solids to taper end of the bowl,and discharges them out of centrifuge from residual outlet.Meanwhile ,liquid phase with smaller density forms a liquid ring layer and discharges from bowl through overflow port,the bowl and spiral pusher run at a high speed simultaneously ,for there exists speed discrepancy,deposited solids on the wall of bowl could be conveyed to residue outlet by spiral pusher.This separation process carry out continuously.

Separation technique

Feeding-gravitational separation-liquid discharge-sediment discharge.

Separation effect factors Centrifuging factor ,length to diameter ratio of cavity ,depth of fluid pool.

Field control

Bowl rotating speed ,rotative speed difference,between,spiral pusher and bowl depth of liquid pool.

The purpose of separation is to separate out substances with different mass ratios from mixed fluid.Separation forms included solid-liquid separation,liquid-liquid separation and liquid-liquid-solid separation.

When mixed fluid enters rotating bowl of centrifuge through feed tube ,solids with larger density would rapidly deposit on inner wall of the bowl,forced by centrifugal acceleration.Then spiral pusher pushed deposited solids to taper end of the bowl,and discharges them out of centrifuge from residual outlet.Meanwhile ,liquid phase with smaller density forms a liquid ring layer and discharges from bowl through overflow port,the bowl and spiral pusher run at a high speed simultaneously ,for there exists speed discrepancy,deposited solids on the wall of bowl could be conveyed to residue outlet by spiral pusher.This separation process carry out continuously.

Separation technique

Feeding-gravitational separation-liquid discharge-sediment discharge.

Separation effect factors Centrifuging factor ,length to diameter ratio of cavity ,depth of fluid pool.

Field control

Bowl rotating speed ,rotative speed difference,between,spiral pusher and bowl depth of liquid pool.

Scope of application:

Application fields

1. Food

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

Specification

Model | Dia mm | Ratio | Speed rpm | G force | Main Motor kW | Back Motor kW | Capacity m3/h | Weight kg | Dimension (L×W×H)mm |

LWS350×1435B | 350 | 4.1 | 4000 | 3136 | 22~30 | 7.5 | 4~8 | 2500 | 3400×900×1400 |

LWS450×1845B | 450 | 4.1 | 3800 | 3640 | 30~37 | 11 | 10~15 | 4000 | 4500×1000×1400 |

LWS500×2050B | 500 | 4.1 | 3500 | 3430 | 37~45 | 15 | 15~20 | 5000 | 4900×1200×1470 |

LWS530×2173B | 530 | 4.1 | 3300 | 3232 | 45~55 | 18.5 | 18~22 | 5600 | 5100×1250×1500 |

LWS585×2400B | 585 | 4.1 | 3000 | 2948 | 75~90 | 22 | 25~30 | 6500 | 5300×1300×1750 |

LWS630×2583B | 630 | 4.1 | 3000 | 3175 | 90~110 | 30 | 30~40 | 7800 | 5100×1550×1400 |

Main technical features

1. Industrial design

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively ease resonance during rotating of bi-rotor

When centrifuge works,there is no obvious first-order and two-order resonance regions within designed speed range,meanwhile ,whole vibration intensity of bearing seat is definited within 2mm/s-4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly eliminate phenomenon of liquid ring stalling

Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW550 and even larger models,It would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately ,our engineers have solved this problem thoroughly.

4. Unique technique adopt in main component work-blanks

The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main bearing selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

6. Constant temperature detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-change ability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.It is not only easy to maintain ,but also greatly improve the reliability and safety of equipment.

8. Simplyand safely in bearing disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high-

pressure,during disassemblement bearing from the machine.which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when disassemble bearing.

9.Main bearing lubrication system

There are two kinds of lubrication system for specific product models :

A thin oil lubrication

* Oil pump offers an uninterruptedly power to ensure oil works circularly;

* Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

* Oil filter system ensure lubricant’s cleanliness;

* Oil pressure energy storage system ensure lubrication pump offers an extra oil supply(the pressure is no less than 0.4Mpa) for 5-6 minutes,when power fails accidentally;

* Constant temperature system is available.

B grease lubrication

* Adopt a grease with properties of extreme pressure resistance ,oxidation resistance ,abrasion resistance,water scour

resistance,corrosion-proof and high temperature resistance.

* Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main bearing BH device (patent design)

There are two spare safe bearings at either end of main bearing.When machine works well,they keep certain clearance from bearing inside track to chief axis.When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately then activates emergency shutdown and goes a smooth shut down.This system protects machine free from damaging and ensure production safety.

11. GSRL feeding device (potent design)

New design of internal spiral core tube has got following achieves.Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

Whole machine set design follows concept of advanced industrial design,ensures stability,functionality and safety of whole machine.Also effectively absorbs shear force of dynamic load during operation.

2. Effectively ease resonance during rotating of bi-rotor

When centrifuge works,there is no obvious first-order and two-order resonance regions within designed speed range,meanwhile ,whole vibration intensity of bearing seat is definited within 2mm/s-4mm/s.All of this eliminates extra fatigue damage to components and assembly units from high frequency vibration during operation and sudden vibration when shut down.

3. Thoroughly eliminate phenomenon of liquid ring stalling

Phenomenon of liquid ring stalling happens during heavy duty boot or shutdown process of complete set machine,especially for LW550 and even larger models,It would makes bounce or wild shake,causes extra impact fatigue damage to main bearings,screw bearings and inner parts of rotary bowl.Fortunately ,our engineers have solved this problem thoroughly.

4. Unique technique adopt in main component work-blanks

The manufacturing methods of main component work-blanks are adopt centrifugal casting technique and overall mould-making forging technique,thoroughly avoid risks such as inter-granular corrosion and relaxation of residual stress release in welding joint.

5. Main bearing selection

We use origin bearings of international first-line brands such as SKF,FAG and so on.

6. Constant temperature detection

All fashioning components and assembly units are detected in constant temperature condition,to make sure of actual processing quality meets the requirements of designed precision accuracy.

7. Inter-change ability

Whole machine physical design and processing technique adopted in critical position,ensure all assembly units and bowls of the same centrifuge model interchangeable.It is not only easy to maintain ,but also greatly improve the reliability and safety of equipment.

8. Simplyand safely in bearing disassemblement

One layer of oil film is injected into contact surfaces between bearing and work-piece by high-

pressure,during disassemblement bearing from the machine.which would fundamentally eliminate friction within different parts.As a result,it would reduce 90% of pulling force and lower the risk of damage to high-precision parts when disassemble bearing.

9.Main bearing lubrication system

There are two kinds of lubrication system for specific product models :

A thin oil lubrication

* Oil pump offers an uninterruptedly power to ensure oil works circularly;

* Jet oil lubrication constantly clean and lubricate bearings and reduce temperature;

* Oil filter system ensure lubricant’s cleanliness;

* Oil pressure energy storage system ensure lubrication pump offers an extra oil supply(the pressure is no less than 0.4Mpa) for 5-6 minutes,when power fails accidentally;

* Constant temperature system is available.

B grease lubrication

* Adopt a grease with properties of extreme pressure resistance ,oxidation resistance ,abrasion resistance,water scour

resistance,corrosion-proof and high temperature resistance.

* Optional automatic grease system fills grease on main bearing at designed hours and quantity.

10. Main bearing BH device (patent design)

There are two spare safe bearings at either end of main bearing.When machine works well,they keep certain clearance from bearing inside track to chief axis.When unexpected condition occurs,main bearing got damaged or circle center deviation causing an amplitude of vibration reaches to designed clearance,safe bearings begin to work as main bearing Meanwhile,computer automatic control system would get a feedback of abnormal vibration value on bearing position immediately then activates emergency shutdown and goes a smooth shut down.This system protects machine free from damaging and ensure production safety.

11. GSRL feeding device (potent design)

New design of internal spiral core tube has got following achieves.Without reducing centrifugal acceleration,shorten triangle belt's traction time,reduce disorder of swirling flow and extend separation time.Meanwhile increases inner working pressure of centrifuge,and restrains liquid foaming.

Production workshop

Screw production1

Screw production2:

.

High speed dynamic balance detection1

High speed dynamic balance detection2

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q1.What's your advantage? Why we choose you?

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Certificates

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

GET IN TOUCH WITH Us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap