Shenzhou - High Efficiency Oil Sludge Treatment Separation Sludge Centrifuge Centrifuge & Separator

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd using unique innovative thinking and strong innovation capabilities, we have developed new products with cross-age significance. High-end technologies helps us ensure High Efficiency Oil Sludge Treatment Separation Sludge Centrifuge quality, improve manufacturing efficiency, and reduce manpower input. It has extensive uses in the field(s) of Separation Equipment. Combining all good performance of adopted raw materials, our High Efficiency Oil Sludge Treatment Separation Sludge Centrifuge has been proved to be applied to the field(s) of Separation Equipment.Our staff has tested multiple times that in the applied fields, the product can give out its best performance such as durability and stability.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | Model | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | Thailand, Sri Lanka | Certification: | GMP/CE |

Treatment of ground sludge, sludge at the tank bottom of the oil-gas combined station, and oily sludge in the sedimentation tank

★ Production of ground sludge

During the drilling and test spraying of the oil exploitation process, a large amount of crude oil falls to the ground and is

mixed with soil, sand, water, and other substances to form an oil-soil mixture, which is called ground sludge; according to the nature of the crude oil, the sludge can be divided into heavy sludge and thin sludge; according to the storage time, it can also be divided into fresh sludge and accumulated sludge. The oil content of the ground sludge can generally be 10~30%. Because there are all kinds of domestic garbage at the oil production site, the sludge, in addition to soil and sand, is mixed with other domestic wastes and solid wastes like glass bottles, mineral water bottles, convenient bags, and gauze.

★ Production of sludge at the tank bottom of the oil-gas combined station

If crude oil is stored for a long time in the tank of the oil-gas combined station, the inorganic impurities such as high melting point wax, asphaltene, colloid, and entrained mud and sand in the crude oil will become precipitates together with water, forming oily sludge at the bottom of the tank so as to reduce the effective volume of the tank. And such sludge is called sludge at the tank bottom of the oil-gas combined station.

The waste oil from refineries, petrochemical plants, and other industries is usually dumped directly into large sedimentation tanks. The oily sludge produced via sedimentation is called oily sludge in the sedimentation tank.

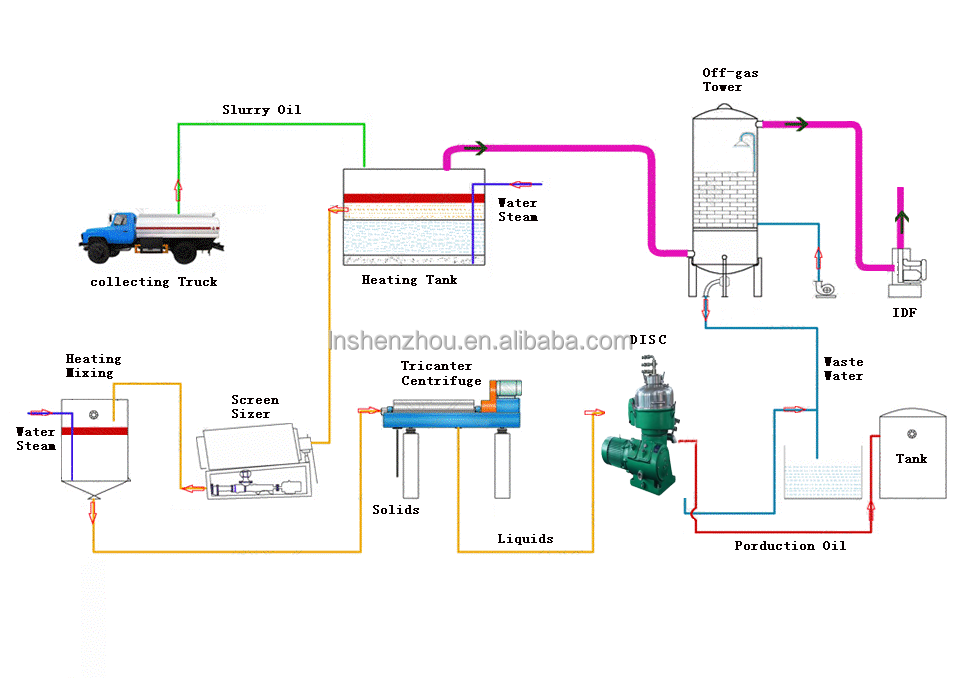

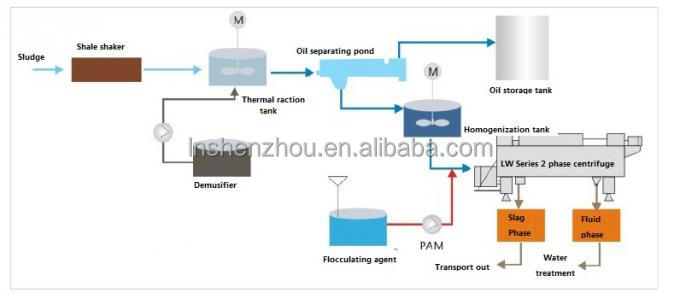

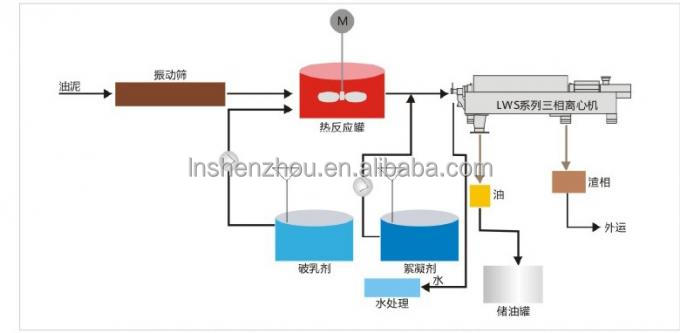

★ Method 1: adopt the high-efficiency LW series two-phase centrifuge treatment plan

After the oily (waste) water is collected and heated by steam, a suitable number of additives like demulsifier and active agent are added in it, so that the oily water in the emulsified state is broken. After demulsification, the oily (waste) water is

naturally settled and separated via the oil trap.

The oil floating on the upper layer of the oil trap is collected and sent to the oil tank to be further treated, while the water

in the middle layer of the oil trap, the oil-water mixture not demulsified, and the sludge settled on the bottom layer are

collected and sent to the stirring tank for further treatment. Then, a high efficiency LW series two-phase centrifuge is used to separate continuously the (oil+water)+slag; the water separated and the oil-water mixture not demulsified are treated via the sewage treatment system. The high efficiency LW series two-phase centrifuge can be used to fulfill the task of dehydration. After that, the crude oil residue in the slag phase can be recovered through the combustion or thermo desorption process. Before the ground sludge is heated and broken, it needs to be screened by vibration to remove large mud particles, sand, glass bottles, mineral water bottles, convenient bags, gauze, and other solid wastes. After pulping and demulsification, the large particles of sand and stone can be further removed through the vibrating screen and sent to the centrifuge for separation.

For the treatment of oily (waste) water, the purpose is to recover more oil and reduce the oil content in the solid. Therefore,

the role of each section in the whole process system is very important.

1. Demulsifier and surfactant can improve the efficiency of demulsification, enhance the subsequent separation efficiency,

increase the oil recovery rate, and reduce the oil content in the slag phase.

2. Heating can reduce oil viscosity, improve the oil recovery rate, and lower the solid contents of oil and water.

3. Adding PAM flocculant can increase the solid recovery rate and reduce the solid content in the liquid phase.

4. The use of the high-efficiency LW series three-phase centrifuge can improve the separation efficiency, enhance the oil recovery rate, and reduce the oil content of the slag phase.

5. Solid-liquid separation realized by using a high-efficiency LW series two-phase centrifuge can reduce the liquid content of the slag phase, facilitate transportation, and increase the combustion heat value.

Separation performance:

1,About 70~85% oil can be recovered (relating to oil density, demulsification effect, temperature, etc.), and the recovered oil can be used for refining purpose after further purified by the flottweg separator;

2,The dryness of the slag phase after centrifugation can reach 40 ~ 60%, and its total volume is reduced by over 80% compared to that before separation;

Before the ground sludge is heated and broken, it needs to be screened by vibration to remove large mud particles, sand, glass bottles, mineral water bottles, convenient bags, gauze, and other solid wastes. After pulping and demulsification, the large particles of sand and stone can be further removed through the vibrating screen and sent to the centrifuge for separation.

Separation performance:

1,About 80~90% oil can be recovered (relating to oil density, demulsification effect, temperature, etc.), and the recovered oil can be used for refining purpose after further purified by the flottweg separator;

2,The water content of the oil phase after separation can reach ≤3 ~ 5%;

3, The dryness of the slag phase after centrifugation can reach 40 ~ 60%, and its total volume is reduced by over 80% compared to that before separation;

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

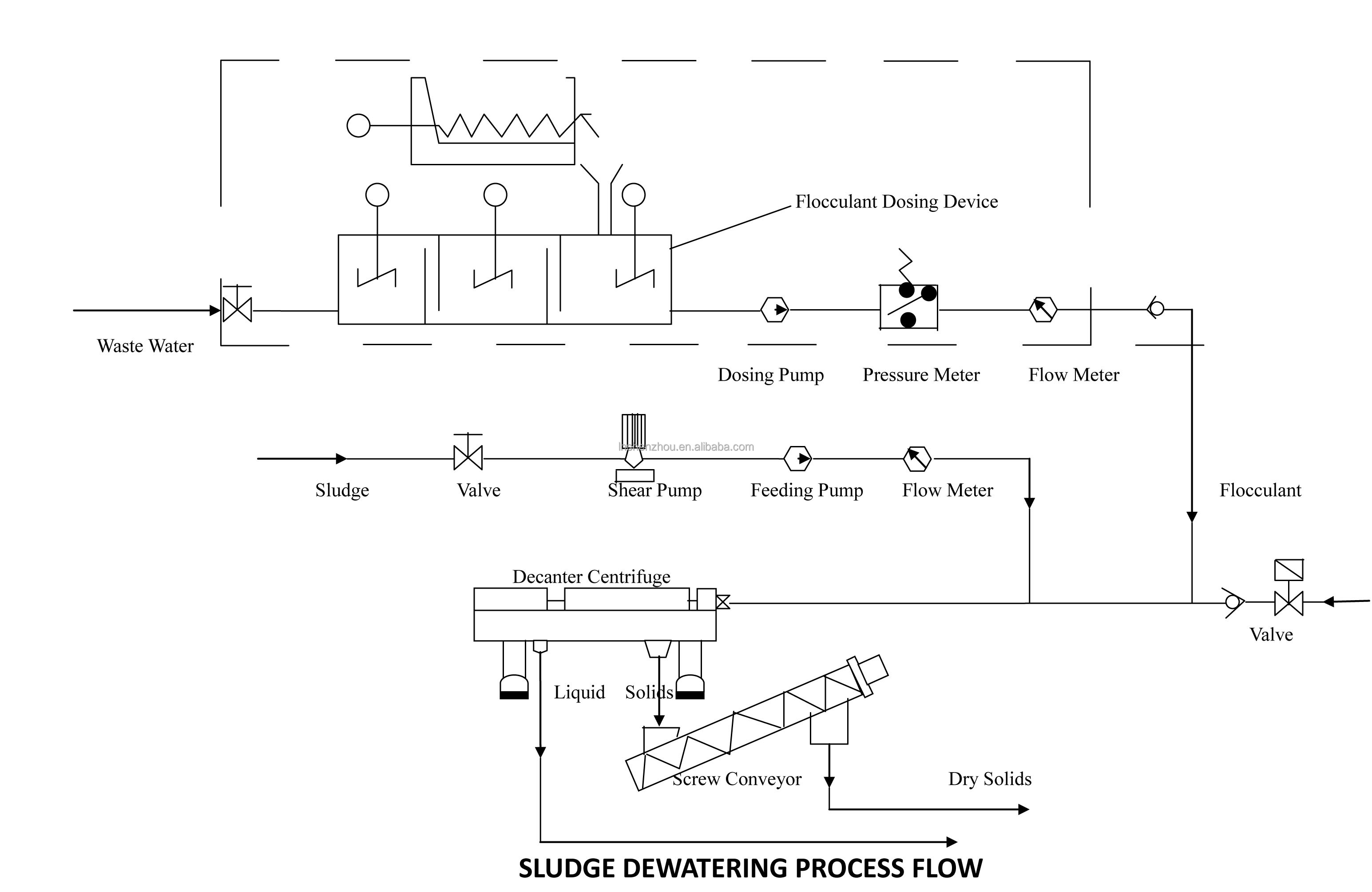

General Description of Waste Water Treatment Centrifuge

For water purification plants, sewage treatment plants, high-performance water treatment dedicated decanter centrifuge is an ideal solution; it highly adapts to the sludge features, but also has a greater process capacity to handle at low concentrations (SS 0.5 %) case without thickener / concentrator to meet the process aim of concentration and dewatering.

Process Description

The remaining sludge from the sludge pit (primary sediment, secondary sediment) going though the shear pump which smash the glass, plastic bags. The feeding pump feed the sludge (concentration 0.5 ~ 4%, or higher) into the centrifuge, at the same time, dosing pump is automatically dosing flocculant (concentration 1 ~ 3 ‰) into the pipeline. Therefore, the sludge turned to be pellet floc before enter the centrifuge. After the separation of the centrifuge, the dewatered mudcake is discharged from the drum and discharged to the outside through a screw conveyor. The dewatering system is widely used in municipal wastewater treatment such as oxidation ditch, AB, A / O, A2 / O, SBR and MBR processes as well as traditional sewage treatment processes.

Featurers:

1. Water content in dewatered solids: 65%-81%

2. Solids content in liquid after separation: lower than 0.05~0.2%

3. Solids recycle rate: no less than 85%~98%

4. Chemical consumption per ton dry solids: 1~5kg/TDS

Our Centrifuge Application Scope: chemistry; pharmacy; biotechnolog; food and beverage industry; animal fat and regenerative fuels ; wastewater; oil sludge; phytoextraction, extraction,

2)When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.

3)After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force, the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum,the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.

4)The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Following allocation can be possible to meet customer's demand

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Screw production1

Screw production2:

High speed dynamic balance detection1

High speed dynamic balance detection2

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.