Shenzhou - Waste Oil Water Solids Oil Sludge Centrifuge Three Phase Variable Frequency Technology Centrifuge & Separator

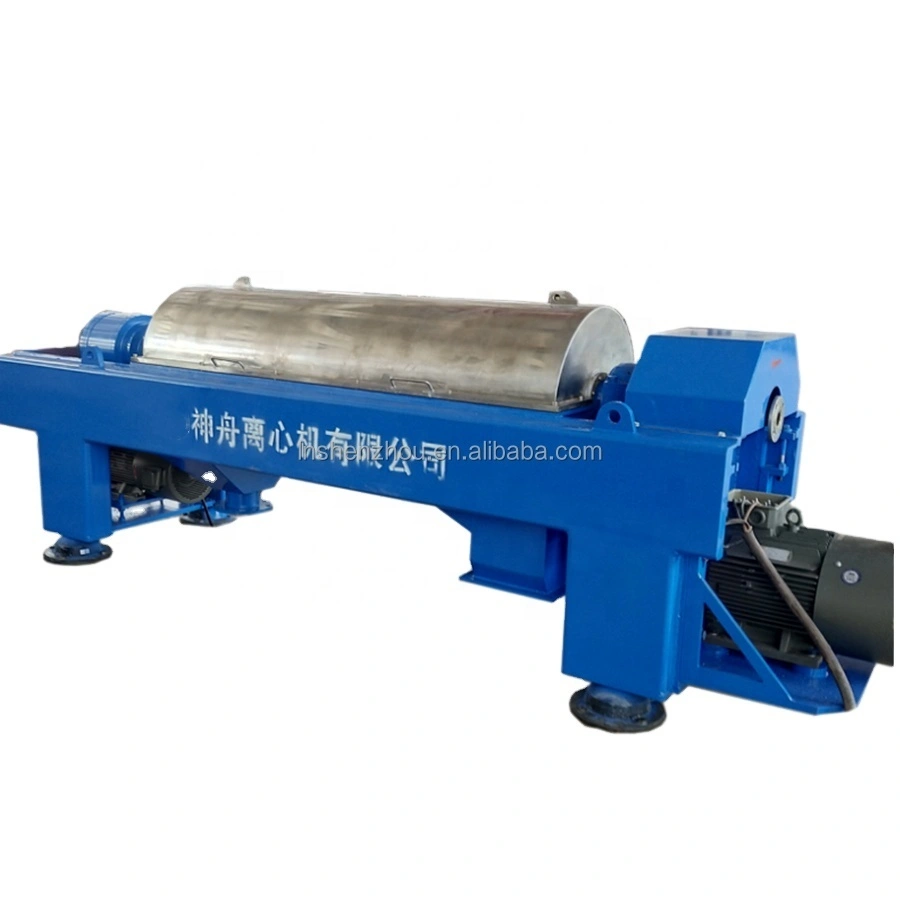

Several tests prove that our Decanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge is a kind of product combining aesthetics, functions, and practicality. With its characteristics, it is able to be used in the application field(s) of Separation Equipment and so on. Customers can be worry-free because the tests prove that the product is stable and excellent when being used in those fields. High-quality Waste Oil Water Solids Oil Sludge Centrifuge Three Phase Variable Frequency Technology rely on strong research and development capabilities and a good brand image. The research and development of Waste Oil Water Solids Oil Sludge Centrifuge Three Phase Variable Frequency Technology has further improved the company's market competitiveness.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 1050 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

The decanter centrifuge is for continuous separation of liquid-solid systems consisting of liquid and solids. Stock liquid is

brought into the bowl through a centrifugal pump. Solid matter settles into outer larger by the centrifugal force. The settled

sediment is pushed into the drying area at the cone of the bowl by rotary difference between spiral and bow land discharged from the outlet. The liquid phase flow out from the liquid outlet.

The drum and scroll conveyor are made of stainless steel and titanium resisting corrosion. The scroll conveyor was coated with wearable alloy or welded with alloy plate. Stepless speed regulation for the bowl. Step or stepless speed regulation for scroll's differential speed. Simple lubrication. Safety protection: rotation rate detection over, vibration protection, motor overload and overheat protection, protection for scroll when zero differential speed occurs.

For the highly sticky materials, it can add the hydraulic differential gear to stabilize.The centrifuge is a specially developed

continuous Solid-Bowl horizontal Scroll. Discharge centrifuge for effective separation of slurries into liquid-solid

phases/liquid-liquid-solid phases, with the application of centrifugal sedimentation principle.

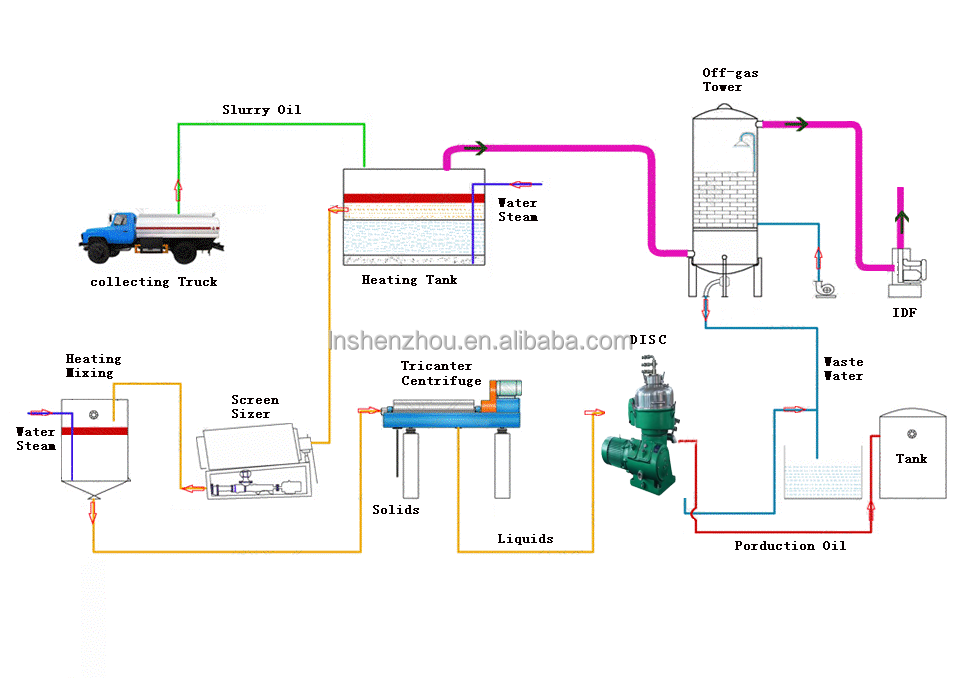

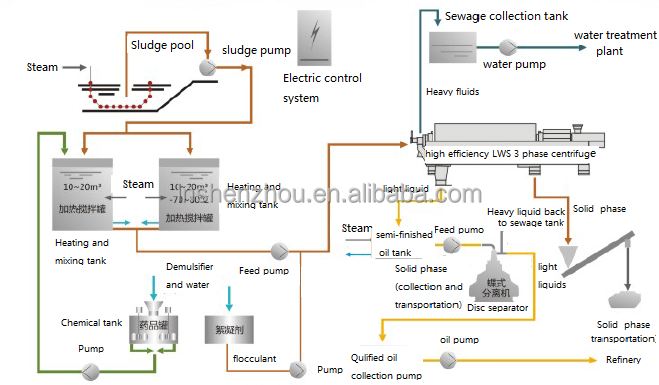

Sludge treatment is a complete set of production process, using the principle of oxidative demulsification and centrifugal

separation. Its main equipment is composed of dosing system, feeding system, separation system, conveying system, and control system.

After the oily sludge is collected and heated by steam, a suitable number of additives like demulsifier and active agent are

added in it, so that the oily water in the emulsified state is broken. After demulsification, a high-efficiency LWS series

three-phase centrifuge is adopted to realize the continuous separation of oil, water, and slag in the oily sludge, and the water separated and the oil-water mixture not demulsified are directly sent to the sewage treatment system for treatment. Then, a LW series two-phase centrifuge with high efficiency is used for dehydration. The crude oil residue in the dehydrated slag phase can be recovered by the combustion or thermal desorption process. The separated crude oil is collected and then purified by a three-phase flottweg separator. The purified oil can be reused.

Separation performance:

1, About 80~90% oil can be recovered (relating to oil density, demulsification effect, temperature, etc.), and the recovered oil can be used for refining purpose after further purified by the SZ separator;

2, The water content of the oil phase after separation can reach ≤3 ~ 5%;

3, The dryness of the slag phase after centrifugation can reach 40 ~ 60%, and its total volume is reduced by over 80% compared to that before separation;

★ Extremely low infrastructure investment and good on-site operating environment

Compared with the conventional filter-type equipment (plate-and-frame filter, belt machine, etc.), the high-performance

centrifuge is compact and efficient, covering only about a third of land, needless of auxiliary gas source, high-pressure water, and with simpler pipe structures at the inlet and outlet. Moreover, the operation environment is more humanized, and the skid-mounted integrated device has the characteristics of compact structure, convenient installation, low requirements for infrastructure, and convenient movement. The centrifuge is widely used in the harmless treatment of oily sludge in oilfield

drilling.

★ Stable operation, low failure rate, and low maintenance cost

Compared with the filter type equipment, the centrifuge does not require any filter cloth or filter screen, so as to avoid the

trouble of clogging and of replacing the filter cloth. The operation and maintenance costs of the equipment are low.

★ Modular design, easy to operate

Our design philosophy: To lower the requirements on the skills, educational level, and labor intensity of operators, and realize one-button start and stop of the control system, fault self-diagnosis, and safety self-protection.

★ Operator configuration and labor intensity

The high-performance centrifuge is an automatic and continuous working mode for feeding-separating-slag (liquid) discharging. The whole process requires no human intervention. Multiple sets of equipment require only one inspector (in conjunction with other positions). Unlike frame and plate-and-frame filter, the slag discharging process does not require manual cutting, greatly reducing the labor intensity of the operator.

★ Ingenious, unique, and diversified heavy liquid-phase discharging structure

The heavy liquid phase separated by the three-phase centrifuge can adopt two different liquid discharging modes, namely gravity discharging and discharging through the built-in centripetal pump with pressure, wherein the latter includes liquid layer fixed mode and the online adjustable mode of heavy phase liquid layer, which is selected according to the process conditions.

★ High performance wear-and corrosion-resistant cemented carbide

As the oily sludge contains a lot of hard particles and impurities such as sand, glass, and metal, if the centrifuge does not

adopt reliable wear-resistant configuration, its service life and running stability will be seriously affected. The wear-resistant solution is completely targeted. According to the material characteristics (pH value, corrosive substance, solid particle size hardness, etc.), cemented carbide or ceramic can be selected, and the cemented carbide can be either YG6, YG8, or various modified tungsten-cobalt alloys with the hardness of 89~93 (HRA), which can fully meet the application fields of the centrifuge.

★ High performance stainless steel

The high-performance three-phase centrifuge can recover oil by 90%~95% and adapts to the liquid density difference (oil and water comparison) of the gas and oil of different densities (0.1~0.08 g/cm3). The centrifuge needs more than 3000G separation factor to achieve better separation. To ensure the stability and the service life of the centrifuge, high-strength corrosion-resistant duplex stainless steel SAF2205 is used.

★ High-dryness screw conveyor and drum structure

The dehydration of solid particles relies mainly on strong centrifugal force, high-torque screw extrusion force (pushing torque), and ultra-long solid particle dehydration length. The centrifuge can generate centrifugal force exceeding 3000G, 30 ~ 50% higher than the screw pushing torque of common centrifuges. The screw pusher torque, and the drum dehydration length is 10 ~ 20% longer than that of common centrifuges.

★ High torque involute planetary gear differential

The ultra-high pushing torque requires a high-torque involute planetary gear differential as the foundation. The differential

equipped on the centrifuge features high torque, high speed, low heat generation, and excellent heat dispersion, which ensure that the centrifuge can be used for a long time and stably.

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

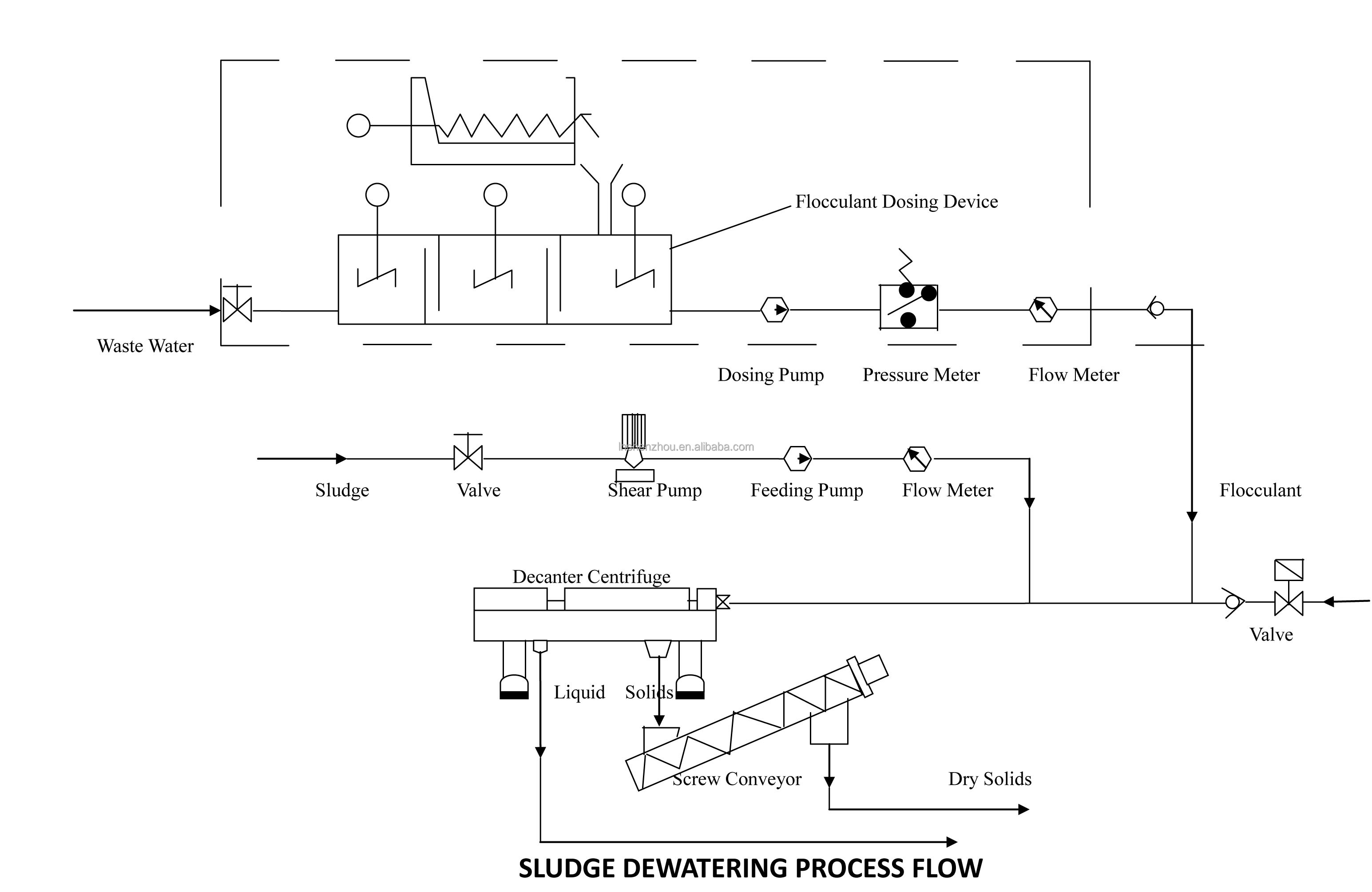

General Description of Waste Water Treatment Centrifuge

For water purification plants, sewage treatment plants, high-performance water treatment dedicated decanter centrifuge is an ideal solution; it highly adapts to the sludge features, but also has a greater process capacity to handle at low concentrations (SS 0.5 %) case without thickener / concentrator to meet the process aim of concentration and dewatering.

Process Description

The remaining sludge from the sludge pit (primary sediment, secondary sediment) going though the shear pump which smash the glass, plastic bags. The feeding pump feed the sludge (concentration 0.5 ~ 4%, or higher) into the centrifuge, at the same time, dosing pump is automatically dosing flocculant (concentration 1 ~ 3 ‰) into the pipeline. Therefore, the sludge turned to be pellet floc before enter the centrifuge. After the separation of the centrifuge, the dewatered mudcake is discharged from the drum and discharged to the outside through a screw conveyor. The dewatering system is widely used in municipal wastewater treatment such as oxidation ditch, AB, A / O, A2 / O, SBR and MBR processes as well as traditional sewage treatment processes.

Featurers:

1. Water content in dewatered solids: 65%-81%

2. Solids content in liquid after separation: lower than 0.05~0.2%

3. Solids recycle rate: no less than 85%~98%

4. Chemical consumption per ton dry solids: 1~5kg/TDS

Our Centrifuge Application Scope: chemistry; pharmacy; biotechnolog; food and beverage industry; animal fat and regenerative fuels ; wastewater; oil sludge; phytoextraction, extraction,

2)When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.

3)After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force, the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum,the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.

4)The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Following allocation can be possible to meet customer's demand

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Screw production1

Screw production2:

High speed dynamic balance detection1

High speed dynamic balance detection2

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.