Shenzhou - decanter centrifuge machine for waste oil industrial separation Centrifuge & Separator

After the oily sludge is collected and heated by steam, a suitable number of additives like demulsifier and active agent are added to it, so as to break the emulsified state of oily water. After demulsification, a high-efficiency LWS series three-phase decanter is adopted to realize the continuous separation of oil, water, and slag in the oily sludge, and the water separated and the oil-water mixture not demulsified are directly sent to the sewage treatment system for treatment. Then, an LW series two-phase decanter with high efficiency is used for the process of dehydration. The crude oil residue in the dehydrated slag phase can be recovered by the combustion or thermal desorption process. After that, the separated crude oil can be collected and purified by a 3 phase disc stack separator to get purified oil which can be reused.

Product Description

Oil sludge is usually generated during the treatment process of oil extraction, refining, pipeline transportation, use, and storage.

Oil sludge treatment is a complete set of production process, using the principle of emulsion breaking and centrifugal separation, and the main equipment is composed of dosing system, feeding system, separation system, conveying system, control system, etc.

Oil Sludge Centrifuge Features and Benefits

Separation Effect

Can recover 80~90% of the oil.

The water content of the oil phase after separation is ≤3~5%.

The dryness of the separated residue phase is 40~60%, and the total volume is more than 80% less than before separation.

Can be further purified by disc stack centrifuge or tubular centrifuge.

Unique Three-phase Separation Structure

The liquid separated by the high-efficiency three-phase centrifuge can be discharged in two different modes: Gravity Discharging and Discharging Through the Built-in Centripetal Pump with Pressure.

Patented Light Phase Adjustment Technology

The light phase liquid adjustment sheet is concealed, and the adjustment can be completed without disassembling the machine.

High Productivity and Adaptability

Three-phase centrifuge is able to recover more than 90%~95% of oil and adapt to materials with different density difference.

Convenience

A wide range of models to choose from.

Provide turnkey project.

High degree of automation, easy to manage.

Easy operation, one-touch start and stop, automatic fault alarm and safety protection.

Cost-effectiveness

Highly adaptable to sludge and has a large treatment capacity.

Adopting advanced control system and high-quality electrical components, reducing the consumption of chemicals and loss of electrical energy.

The floor space of the machine is about 2/3 smaller than traditional filtration equipment.

Continuous automatic work and the slagging process does not require manual operation.

Advanced Technology

Dual Motor Dual Frequency Conversion Common DC Busbar Technology - Energy Saving.

Constant Torque Control Technology - Stable.

Vortex Spiral Discharge Port-High Capacity.

Variable Pitch Technology-Lower Solid-Phase Water Content.

YG6, YG8 Carbide, SAF2205 Duplex Stainless Steel-Good Wear Resistance.

Decanters for Oily Wastewater Treatment Process

At present, for the oily wastewater produced by refineries in the process of processing crude oil, the treatment mode of rough flocculation + dewatering is often used, and the residue phase is directly treated by incineration after dewatering. This treatment mode will cause a waste of crude oil resources. Now we can use high-efficiency LWS series three-phase centrifuge after a series of pretreatment (adding emulsion breaker, surfactant, etc.) to realize the resource utilization of crude oil.

Separation Effect

Can recover 80~95% of the oil.

The water content of the oil phase after separation is ≤3~5%.

The dryness of the separated residue phase is 40~60%, and the total volume is more than 80% less than before separation.

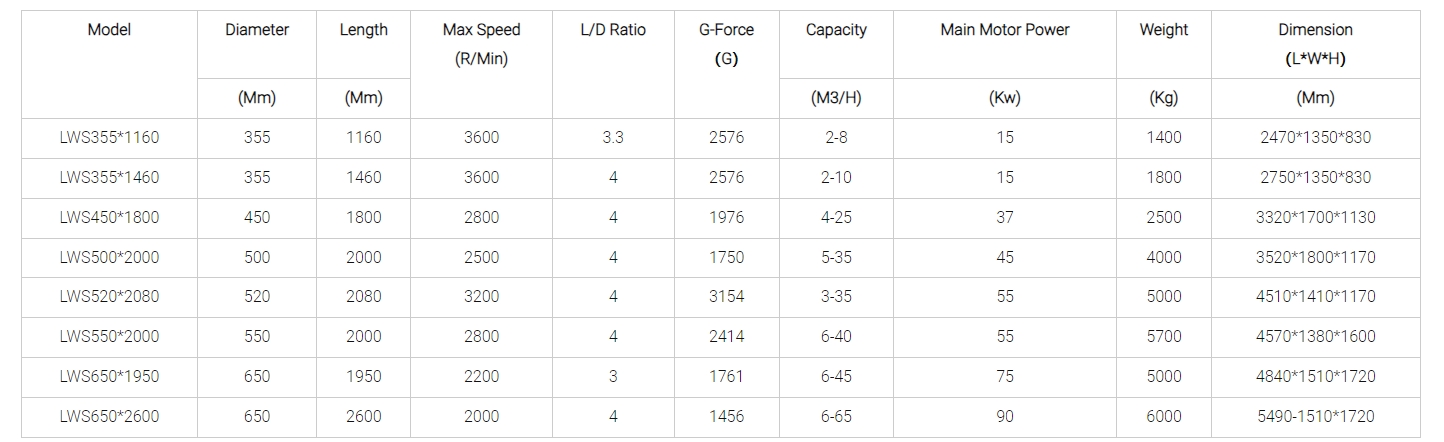

Product parameters:

Customers:

Pacakage show: