Application of Decanter Centrifuges in Amino Acid Separation

|  |

**Application of Decanter Centrifuges in the Amino Acid Industry**

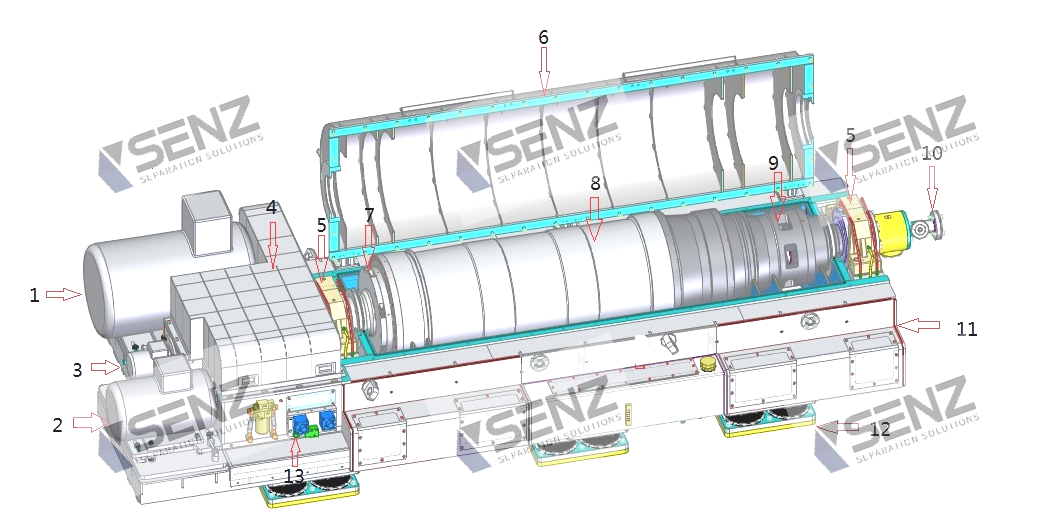

Decanter centrifuges are the **core solid-liquid separation equipment** throughout the entire amino acid production process. They play a crucial role in key stages such as fermentation broth pretreatment, crystallization purification, and waste liquid recovery. Through efficient centrifugal separation, they enable impurity removal, crystal enrichment, and resource recovery, thereby significantly improving product yield, purity, and the environmental friendliness of production.

**Core Application Stages**

* **Fermentation Broth Clarification and Pretreatment:**

After amino acid fermentation, the broth contains a large amount of solid impurities such as bacterial cells, mycelia, and medium residues. Decanter centrifuges can rapidly separate these impurities to produce a clear crude extract. This prevents contamination of subsequent ion exchange resins or membrane modules, laying a solid foundation for subsequent purification steps.

* **Post-Crystallization Solid-Liquid Separation:**

After amino acids are concentrated and crystallized at their isoelectric point, decanter centrifuges separate the crystals from the mother liquor. This process achieves a high amino acid crystal recovery rate (typically exceeding 95%), reducing the loss of target products. The separated mother liquor can be recycled back to the previous process for re-extraction, further enhancing resource utilization efficiency.

* **Waste Liquid and By-Product Recovery:**

Decanter centrifuges treat solid residues in production waste liquid, reducing the load on sewage treatment systems. Additionally, they can recover incompletely extracted amino acids from the residues or separate high-purity bacterial proteins (which can be used as feed ingredients), realizing the high-value utilization of by-products.

* **Auxiliary Separation in Refining Processes:**

After amino acid refining (e.g., decolorization, desalination), if the feed liquid still contains trace solid impurities, decanter centrifuges can perform deep clarification. This ensures the final product meets purity standards (e.g., food-grade amino acid purity ≥ 99%).

**Core Advantages in Applications**

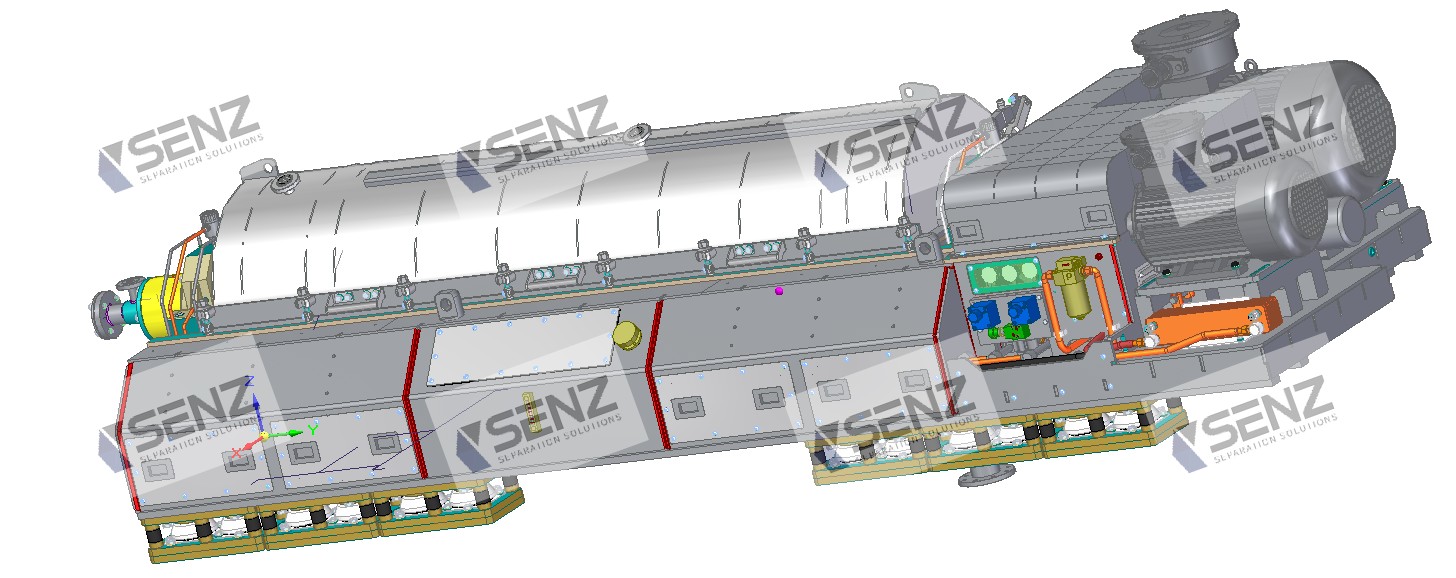

* **Suitability for Large-Scale Production:**

They support continuous operation with a processing capacity ranging from **5 to 50 m³/h**, eliminating the need for shutdowns for slag discharge. This aligns perfectly with the high-efficiency production requirements of ten-thousand-ton-scale amino acid production lines.

* **High Separation Precision:**

With a separation factor of up to **2000-3000**, they can effectively separate fine particles as small as **≥ 0.005 μm**. The resulting clarified liquid has high transmittance, minimizing impurity interference in subsequent purification steps.

* **Material and Process Compatibility:**

Wetted parts are constructed from **304/316L stainless steel**, offering excellent corrosion resistance against acidic or alkaline amino acid fermentation broths. The centrifuges can handle feed liquids with high viscosity (≤ 100 mPa·s) and high solid content (1-40%), making them suitable for the production processes of various amino acids such as glutamic acid, lysine, and threonine.

* **Environmental Friendliness and Cost Optimization:**

They eliminate the need for filter aids, thereby reducing sludge generation. Their high degree of automation (frequency conversion control, automatic slag discharge) lowers labor costs. The recovery and reuse of water resources and by-products are in line with the requirements of green production.

|  |

**Typical Application Cases**

* **Glutamic Acid Production:**

A biotechnology company's 50,000-ton-per-year glutamic acid production line employs a "disc centrifuge for rough separation + decanter centrifuge for fine separation" process. The decanter centrifuge, with a processing capacity of 30 m³/h, achieves a bacterial cell removal rate exceeding 98% and a total glutamic acid yield of 96%. The recovered bacterial protein creates an annual additional value exceeding 5 million RMB.

* **Lysine Refining:**

An amino acid enterprise uses decanter centrifuges to separate crystals from the mother liquor after lysine crystallization. This reduces the crystal moisture content to below 15%. After recycling the mother liquor for re-extraction, the total lysine yield increases by 8%, saving approximately 3 million RMB in raw material costs annually.

* **Threonine Wastewater Treatment:**

In a threonine production project, decanter centrifuges are used for the pretreatment of fermentation waste liquid. After separating solid residues, the COD (Chemical Oxygen Demand) removal rate of the wastewater reaches 60%, reducing subsequent sewage treatment costs by 40%. Simultaneously, the recovered bacterial protein is utilized as a resource.

**Key Technical Adaptation Points**

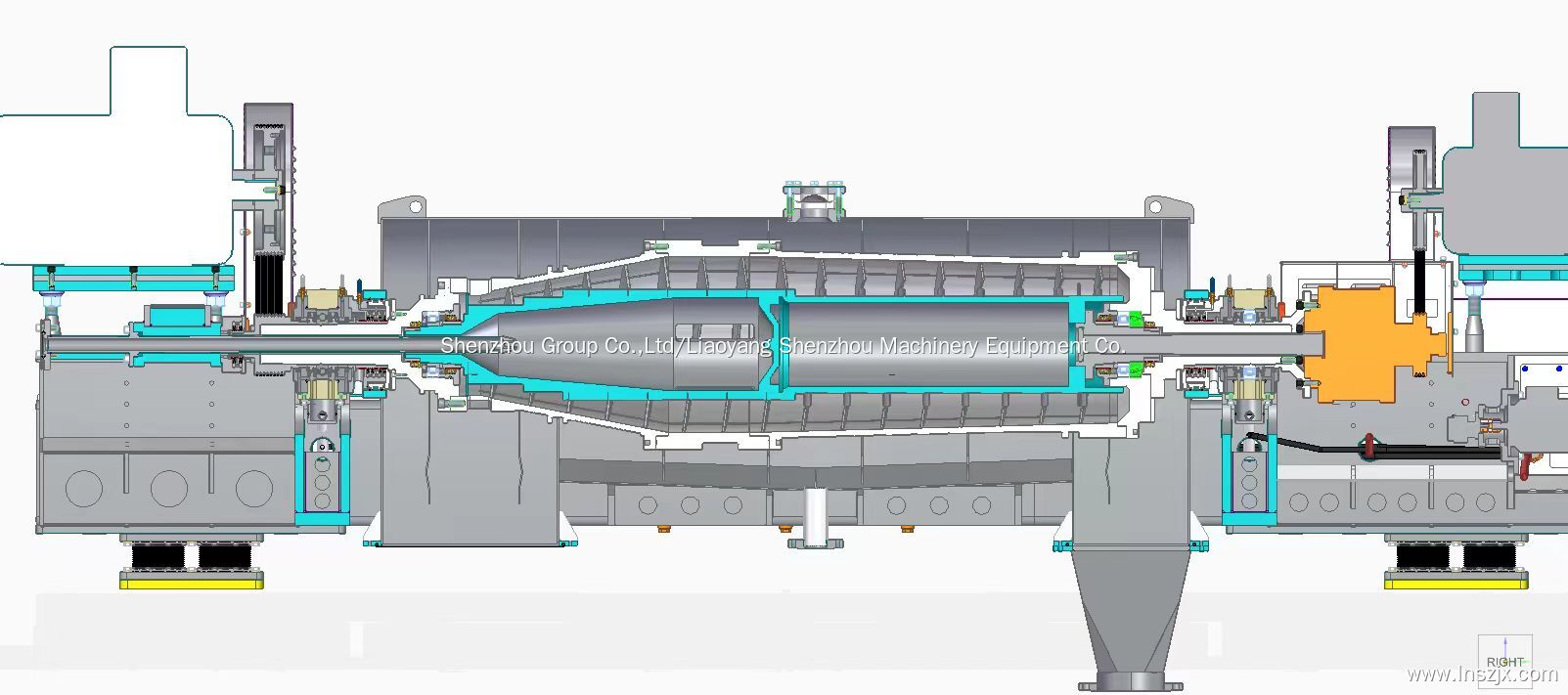

* **Parameter Adjustment:**

For different amino acid feed liquids, adjust the rotational speed (3000-4500 rpm) and differential speed (5-30 rpm) to balance separation efficiency and crystal recovery rate. For feed liquids with fine particles, appropriately increase the rotational speed to enhance centrifugal force.

* **Material Selection:**

When handling acidic fermentation broths (e.g., glutamic acid broth with a pH of 2-3), **316L stainless steel** is preferred for wetted parts. The stator should be made of acid and alkali-resistant rubber to prevent equipment corrosion by the feed liquid.

* **Process Integration:**

Decanter centrifuges are often used in conjunction with disc centrifuges (for rough separation to remove large particles) and ceramic membrane filtration (for precision purification). This forms a complete "rough separation - fine separation - refining" process chain, further improving product purity.

|  |