Application of Decanter Centrifuges in Pectin Separation

Decanter centrifuges are core equipment for the industrial separation of pectin. With their adaptability to high-viscosity materials, continuous operation capability, and efficient solid-liquid separation performance, they perfectly match the characteristics of pectin extracts (high viscosity, containing fibrous impurities). The following is a detailed explanation from the perspectives of technical principles, application scenarios, core advantages, operation key points, and development trends:

I. Technical Principles and Adaptability

1. Core Structure and Separation Logic

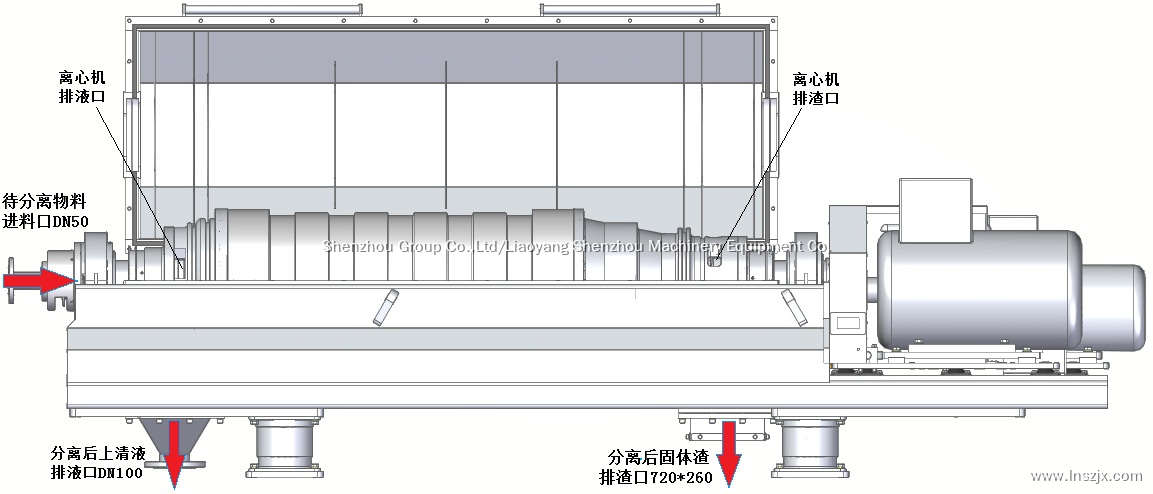

A decanter centrifuge consists of a rotating drum (diameter: 200-1200 mm) and a screw conveyor, which rotate in the same direction with a small speed difference (0.3%-2% of the drum speed). After the pectin extract (mostly obtained from acid or enzyme extraction of citrus peels or apple pomace) enters the equipment, under the action of a separation factor of 1200-3500g generated by a rotational speed of 3000-5000 rpm:

High-density impurities (peel debris, fibers, starch particles) are thrown to the inner wall of the drum, forming filter residue;

The clarified pectin-containing extract (water-soluble pectin exists in a colloidal state) remains in the center of the drum and is discharged through the overflow port;

The screw conveyor continuously pushes the filter residue to the slag discharge port, realizing continuous solid-liquid separation.

2. Key Parameters for Pectin Separation

Feed Characteristic Adaptation: The viscosity of pectin extract is usually 50-500 mPa·s, with a solid content of 1%-8%. Decanter centrifuges avoid material retention or blockage by adjusting the differential speed (0.5%-1.5%) and feed flow rate (5-50 m³/h);

Separation Precision Control: The drum’s length-to-diameter ratio (3-5:1) is designed to enhance sedimentation, enabling the separation of solid impurities with a particle size ≥10 μm and ensuring the efficiency of subsequent pectin purification processes (such as alcohol precipitation and ultrafiltration).

II. Core Application Scenarios

1. Extract Pretreatment (Impurity Removal)

After pectin extraction, the solution contains a large amount of impurities such as peel fibers, cell debris, and undissolved starch. As primary separation equipment, decanter centrifuges:

Rapidly remove solid impurities, reducing the solid content of the extract from 1%-8% to below 0.2%;

Reduce the viscosity of the extract (from 300-500 mPa·s to 50-100 mPa·s), reducing the load for subsequent purification processes like alcohol precipitation, salting-out, or ultrafiltration;

Adaptable Raw Materials: Pectin extracts from various raw materials such as citrus peels, apple pomace, and sugar beet pulp, especially suitable for treating citrus peel extracts with high fiber content.

2. Pectin Concentration and Enrichment

In large-scale production, it is necessary to concentrate low-concentration pectin extract (pectin content: 0.5%-2%) to 5%-10% to reduce the consumption of subsequent solvents (e.g., ethanol) or drying energy:

Decanter centrifuges achieve preliminary enrichment of pectin colloids through centrifugal force, with a concentration multiple of 3-8 times;

Combined with countercurrent washing function, a small amount of deionized water is added to rinse the filter residue, increasing the pectin recovery rate (up to 92%-96%);

Example: After treating apple pomace pectin extract with a decanter centrifuge, the pectin concentration increases from 0.8% to 4.5%, and the ethanol consumption in the subsequent alcohol precipitation process is reduced by 60%.

3. High-Purity Pectin Refining

For food-grade and pharmaceutical-grade pectin (requiring removal of proteins, pigments, and small-molecule impurities):

Decanter centrifuges are combined with ultrafiltration membranes: large-particle impurities are first removed by centrifugation, and then pectin molecules are retained by 50-100 kDa ultrafiltration membranes, resulting in a purity of over 90%;

For pectin solutions obtained by enzymatic extraction (containing enzymatic hydrolysis products), the separation factor (2500-3000g) can be adjusted to simultaneously remove enzyme proteins and colloidal impurities.

III. Core Advantages

1. Adaptability to High-Viscosity Materials, No Blockage Risk

The viscosity of pectin extract is much higher than that of ordinary fermentation broths. The large-channel drum design (feed port diameter ≥50 mm) and adjustable differential speed of decanter centrifuges prevent fiber impurity entanglement, making them suitable for long-term continuous operation (single-batch operation ≥8 hours).

2. Continuous Operation, Large Processing Capacity

The processing capacity can reach 5-100 m³/h, far exceeding that of tubular centrifuges (1-5 m³/h) and plate-and-frame filters (batch operation). It meets the needs of large-scale pectin production (daily output: 1-5 tons of pectin) without the need for shutdown for slag discharge.

3. High Recovery Rate, Stable Quality

With a high separation factor (1200-3500g), it can effectively capture pectin molecules in a colloidal state to avoid loss; the separation effect is not affected by fluctuations in feed concentration, and the pectin purity fluctuation is ≤3%, meeting the quality requirements of the food industry.

4. High Degree of Automation, Easy Operation

Equipped with a PLC control system, it can real-time monitor the viscosity and solid content of the extract, and automatically adjust the rotational speed and feed flow rate; it is linked with extraction tanks and concentration equipment to realize full-process automation of "extraction-separation-concentration".

IV. Operation Precautions

1. Equipment Selection Key Points

Priority is given to models with a length-to-diameter ratio ≥4:1 to enhance sedimentation; the drum material is 316L stainless steel, which is acid-corrosion resistant (pectin extract pH=2-4);

High-viscosity extracts (≥300 mPa·s) need to be equipped with high-torque differentials to avoid filter residue accumulation.

2. Operation Parameter Optimization

Drum Rotational Speed: 3000-4000 rpm for ordinary pectin extracts, and 4000-5000 rpm for high-fiber raw materials (e.g., citrus peels);

Feed Flow Rate: Controlled at 70%-90% of the equipment’s rated processing capacity to avoid reduced separation efficiency due to overload;

Temperature Control: The feed temperature is maintained at 40-60℃ to reduce the viscosity of the extract and improve separation efficiency (too low temperature may cause pectin coagulation).

3. Cleaning and Sanitation Maintenance

After each operation, circulate and clean with 40-50℃ warm water + 0.5% citric acid solution for 30 minutes to remove pectin residues on the drum and screw conveyor, preventing microbial growth;

Check the dynamic balance of the drum weekly to avoid equipment wear caused by vibration and ensure separation precision.

4. Pectin Quality Protection

Avoid excessively high separation factors (>3500g) to prevent pectin molecular chain breakage and subsequent reduction in gel strength;

Use deionized water or low-concentration citric acid solution as the washing liquid to avoid introducing metal ions that affect pectin stability.

V. Development Trends

1. Intelligent Precision Control

Integrate online viscosity sensors and pectin concentration detectors, and automatically adjust rotational speed, differential speed, and feed flow rate through AI algorithms to realize real-time matching of "raw material characteristics-separation parameters" and further improve the recovery rate.

2. Energy Conservation and Multifunctional Integration

Adopt permanent magnet synchronous motors to reduce energy consumption by 25%-30%; integrate the integrated function of "separation-washing-desalination" to reduce production links and lower solvent and water resource consumption.

3. Adaptation to New Extraction Processes

For high-viscosity pectin extracts from ultrasonic-assisted extraction and microwave extraction, optimize the design of the internal flow channel of the drum to enhance material fluidity; adapt to low-acid extraction processes (pH=3.5-4.5) to reduce equipment corrosion and extend service life.

4. Green and Environmental Protection Upgrading

Adopt a closed structure to reduce emissions of volatile substances (e.g., ethanol); filter residue (fibrous impurities) can be recycled for feed or biomass energy, realizing resource recycling.

| Application Scenario | Raw Material Type | Extract Characteristics |

| Extract Pretreatment | Citrus Peel | High viscosity (300-500 mPa·s), high fiber content |

| Extract Pretreatment | Apple Pomace | Medium-low viscosity (50-300 mPa·s), contains starch impurities |

| Bacterial Concentration | Citrus Peel/Apple Pomace | Pectin concentration: 0.5%-2%; Viscosity: 100-300 mPa·s |

| Refining & Washing | Citrus Peel/Apple Pomace | Crude pectin, contains pigments, proteins and other impurities |

| High-Purity Pectin Production | Citrus Peel | Need to remove pectin molecular chain breakage products |

Citrus Peel: High fiber content (15%-25%) and high extract viscosity require high rotational speed (4000-5000 rpm) and large length-to-diameter ratio (≥4:1) to enhance sedimentation. For example, in the patent for citrus peel residue-liquid separation, a drum with a diameter of 430 mm and rotational speed of 4200-4500 rpm is used, reducing the moisture content of pectin to 40% after treatment.

Apple Pomace: Contains starch impurities (5%-10%), so medium-low rotational speed (3000-4000 rpm) and differential speed adjustment (0.8%-1.2%) are needed to avoid starch gelatinization and blockage. Apple pectin extracted by traditional processes has high viscosity, so priority should be given to models with large processing capacity (e.g., LW450×1800-N).

High Viscosity (>300 mPa·s): For example, ultrasonic-assisted citrus peel extract (348.7 mPa·s) requires a high-torque differential (e.g., LW X300) and a drum with a feed port diameter ≥50 mm to prevent material retention.

Medium-Low Viscosity (50-300 mPa·s): For example, microwave-extracted apple pomace extract can use medium-sized equipment such as LW355×1400, with a processing capacity of up to 30 m³/h.

3. Relationship Between Separation Factor and Rotational Speed

The calculation formula for separation factor (Kc) is: \(K_c = \frac{\omega^2 r}{g}\), where ω is angular velocity (rad/s) and r is drum radius (m). For example, when the drum diameter is 430 mm and rotational speed is 4200 rpm, the separation factor is approximately 3000g.

High-fiber citrus peel materials require Kc ≥2500g;

Medium-low viscosity apple pomace materials only require Kc ≥1500g to meet separation needs.

4. Equipment Material and Maintenance

The drum and screw conveyor are made of 316L stainless steel, with a laser cladding tungsten carbide coating on the surface, which can withstand the acidic environment (pH 2-4) of pectin extract and fiber wear.

It is recommended to circulate and clean with 40-50℃ warm water + 0.5% citric acid solution for 30 minutes every 8 hours to prevent microbial growth caused by pectin residues.

Process Design Recommendations

1. Pretreatment Stage

Citrus peel raw materials must be crushed to a particle size <5 mm; apple pomace must pass through a desander to remove sand particles and reduce equipment wear.

For high-viscosity extracts, 0.1%-0.3% pectinase can be added for enzymatic hydrolysis pretreatment to reduce viscosity by 30%-50% and improve separation efficiency.

2. Multi-Stage Separation Process

Adopt the combined process of "rough separation (decanter centrifuge) + fine separation (disc centrifuge)" to increase pectin purity from 80% to over 95%, which is suitable for pharmaceutical-grade product production.

During the washing stage after alcohol precipitation, a decanter centrifuge can be used for three-stage countercurrent washing, reducing ethanol consumption by 40% while increasing pectin recovery rate to 98%.