Shenzhou Decanter Centrifuge LW900

The LW Decanter Centrifuge, also known as a horizontal decanter centrifuge or decanter separator, has a wide range of applications in various industries. As a prominent decanter centrifuge manufacturer in China, the LW Decanter Centrifuge offers efficient separation and has gained popularity in several fields. Here are some common applications of the LW Decanter Centrifuge.

Wastewater Treatment: The decanter sludge separator plays a crucial role in wastewater treatment processes. It effectively separates solid particles, such as sludge or sediment, from wastewater, allowing for the removal of contaminants and the production of clean water.

Oil and Gas Industry: In the oil and gas industry, the LW Decanter Centrifuge is utilized for various purposes. It can be used to separate oil, water, and solids in drilling mud, enabling the recovery of valuable oil and minimizing environmental impact. Additionally, it aids in the dewatering of sludge generated from oil refineries and offshore platforms, facilitating proper waste management.

Food and Beverage Processing: The horizontal decanter centrifuge is employed in the food and beverage industry for solid-liquid separation. It assists in separating liquids from solids in processes like fruit juice extraction, vegetable oil. By efficiently separating the desired components, it helps ensure product quality and consistency.

Chemical and Pharmaceutical Industries: The decanter sludge separator can be employed to separate and clarify various chemical suspensions, pharmaceutical intermediates, and API (Active Pharmaceutical Ingredient) compounds.

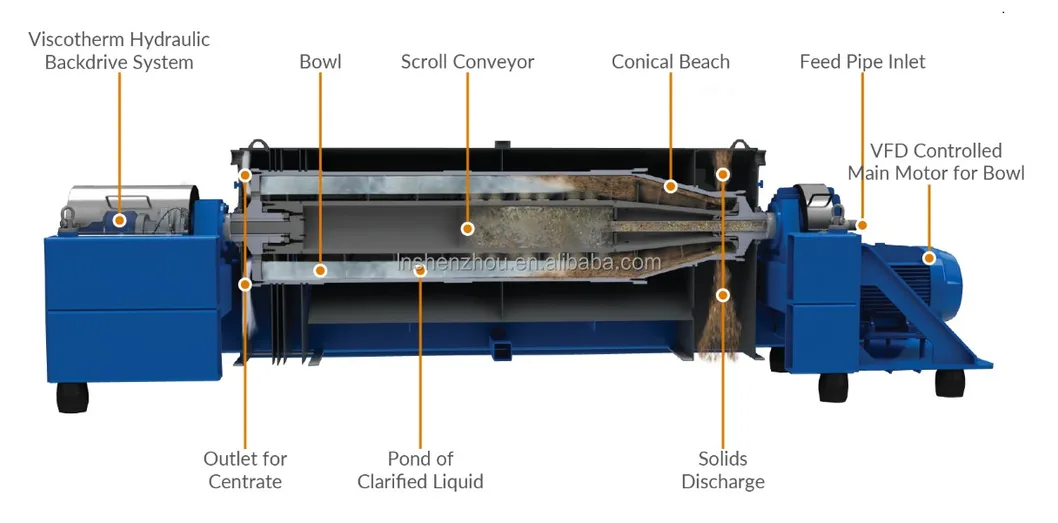

LW Decanter Sludge Separator Working Principles

The decanter centrifuge machine starts and speeds up automatically. When the proper working condition are met and the revolving drum reaches the feeding speed, the feeding valve opens and allows suspension which will be separated to into the product compartment of spiral feeder through the feeding pipe. After the preliminary speed-up, suspension passes the outlet of compartment and into the drum. Because of centrifugal force, the suspension in the drum is quickly divided into two phases. The heavier solid phase deposits to the inner wall of the drum and driven by the different gear which results in the non-cynchronous movement between the spiral feeder and the drum. The solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet. The separated liquid flows out through the big end or will be driven out by centrifugal pump.

Item/Model

LW-250×1000

LW-350×1460

LW-450×1800

LW-520×2130

LW-650×2275

LW-720×2665

LW-900×2700

LW-1000×2500

Drum diameter (mm)

250

350

450

520

650

720

900

1000

Drum effective length (mm)

1000

1460

1800

2130

2275

2665

2700

2500

Max. Speed (r/min)

4000

4000

3600

2800

2500

2000

1500

1500

Max. Separating factor (N)

2238

3133

3265

2281

2273

1611

1133

1259

Processing capability (m3/h)

0.5-3

3-12

6-20

12-30

25-35

45-100

50-110

50-120

Main Motor power (Kw)

11

22

30-45

45-75

75-110

110-160

160-220

280

Overall dimension (mm)

2740×700

×900

3950×830

×1170

4385×1140

×1508

4760×1250

×1554

5120×1450

×1750

5500×1550

×1850

5800×1750

×2050

5600×1850

×2150

Weight (Kg)

1200

2250

3200

5600

7800

14000

19000

25000

- Year Established1980

- Business TypeFactory

- Country / RegionZhejiang Province

- Main IndustryGeneral Mechanical Components Design Services

- Main ProductsDecanter centrifuge,Disc Centrifuge,Tubular Centrifuge,Plate Centrifuge

- Enterprise Legal PersonXuhongmei

- Total Employees16~100 people

- Annual Output Value10000000USD

- Export MarketEastern Europe,Latin America,Africa,Southeast Asia,America,Others

- Cooperated Customers--

Some of our machines gained the new technology invent patent.We are on of the world’s leading manufacturers of decanter centrifuge,disc centrifuge,tubular centrifuge,separation systems and drying equipment.Now there are over 180 series or decanter centrifuges and disc separators used home and abroad.Including U.S.A , Canada ,Australia,Russia ,Brazil,Singapore and so on totally 70 countries.

We own various kinds of inspection and testing facilities with value over USD10 million .18 testing tables,high speed dynamic balancing machine,ultrasonic flaw detection machines.etc.

We are equipped with complete testing,inspection,analysis control system ,advanced testing machines and stimulative working condition test table and automatic control testing system,which guarantees our new product research ,processing validation and quality.

We also welcome OEM and ODM orders.Whether selecting a current product from our catalog or seeking engineering assistance for your application,you can talk to our customer service center about your sourcing requirements

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.