Shenzhou - low speed centrifuge Centrifuge & Separator

At present, the basic rules of design in our company are to keep customer-oriented and industry-driven. Our low speed centrifugehas a look that is unique enough to grab the attention of most of the customers. Moreover, it has the tested performance and so on. These aspects can prove the value of the product. High-end technologies helps us ensure low speed centrifuge quality, improve manufacturing efficiency, and reduce manpower input. It has extensive uses in the field(s) of Separation Equipment. Our goal is to exceed the quality expectations of our customers. This commitment starts with the top-level management and extends through the entire enterprise. This can be achieved through innovation, technical excellence, and continuous improvement. In this way, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd firmly believe that we will satisfy the growing needs of every customer.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | Model | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | Thailand, Sri Lanka | Certification: | GMP/CE |

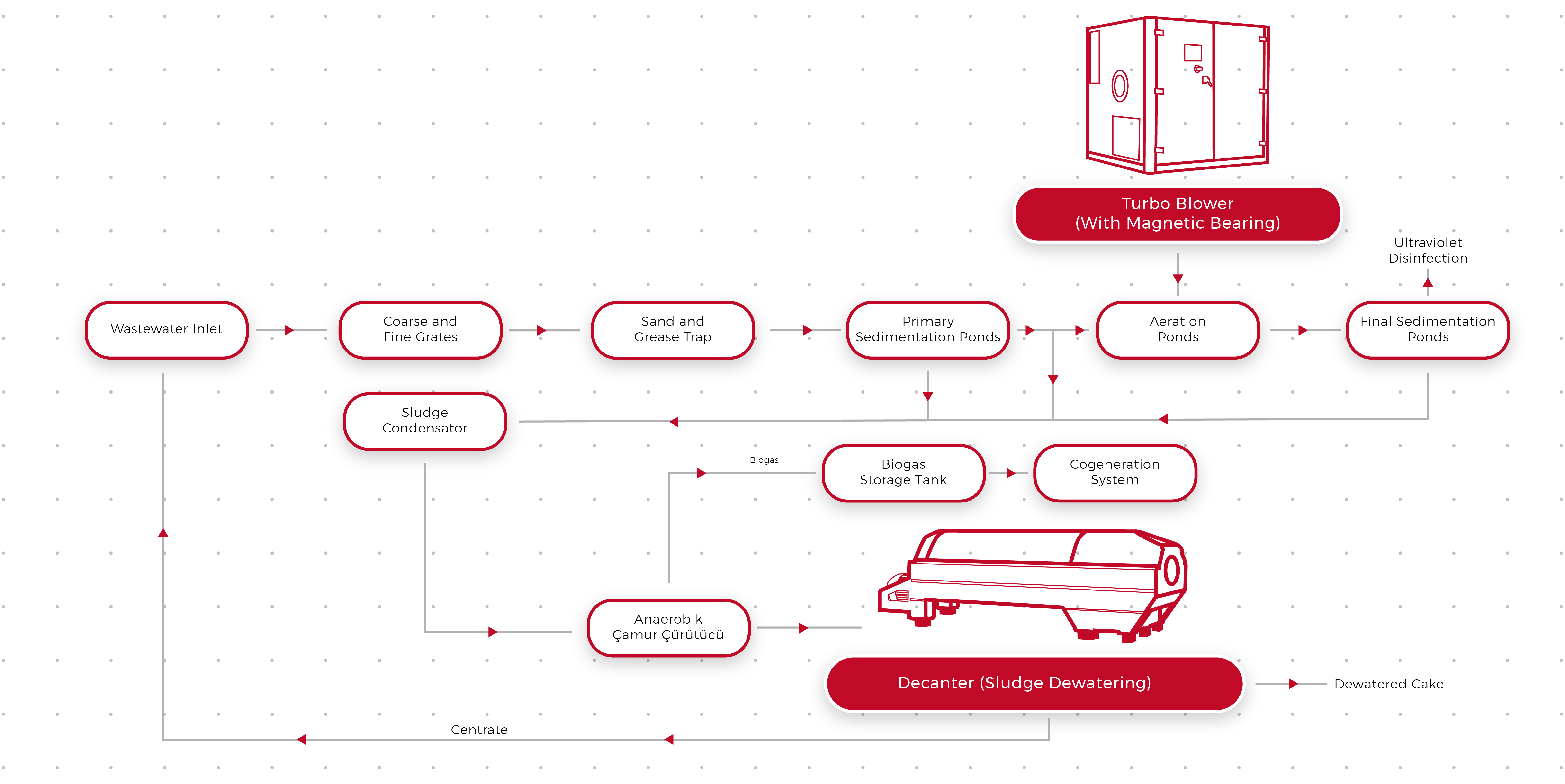

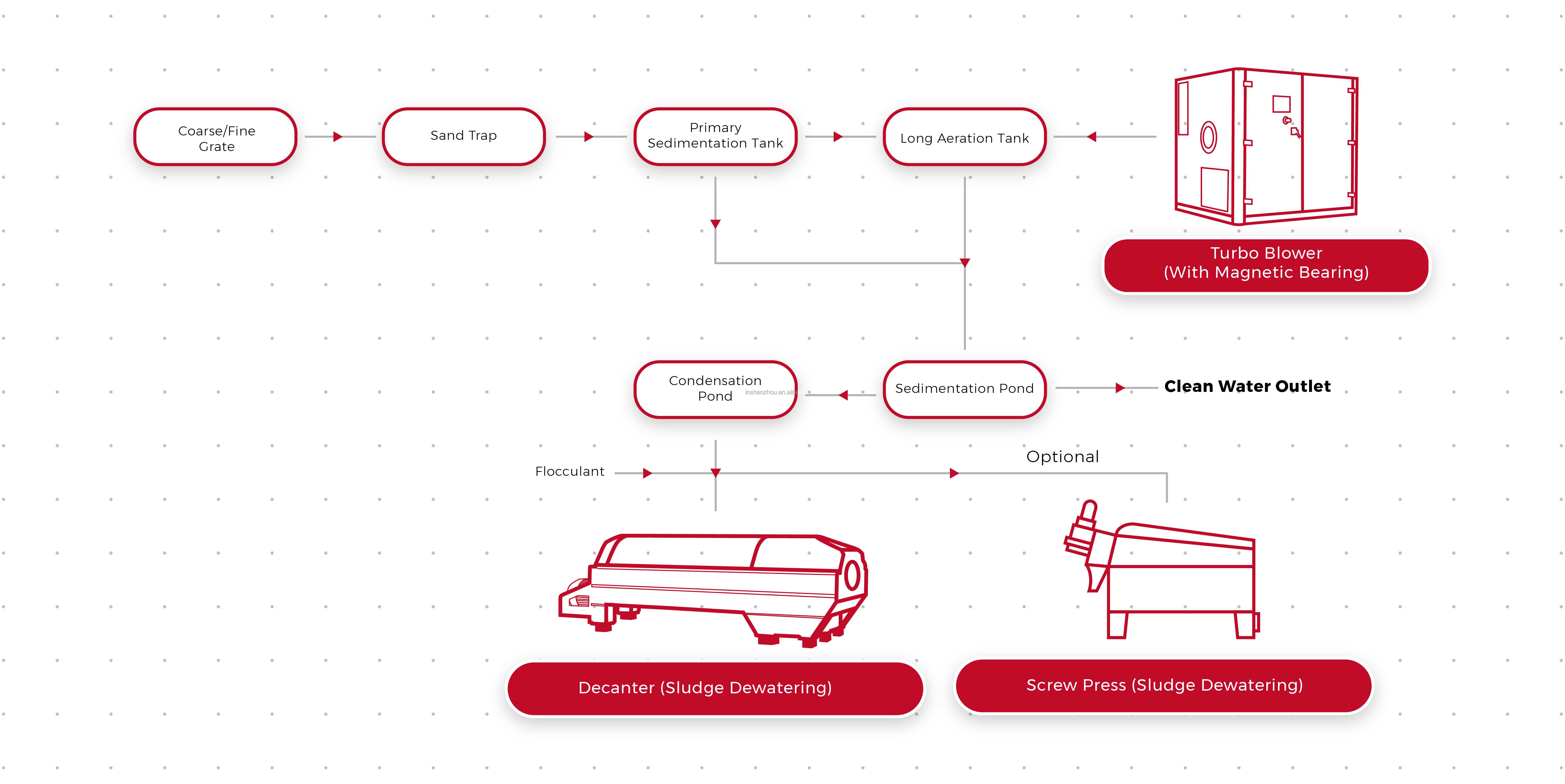

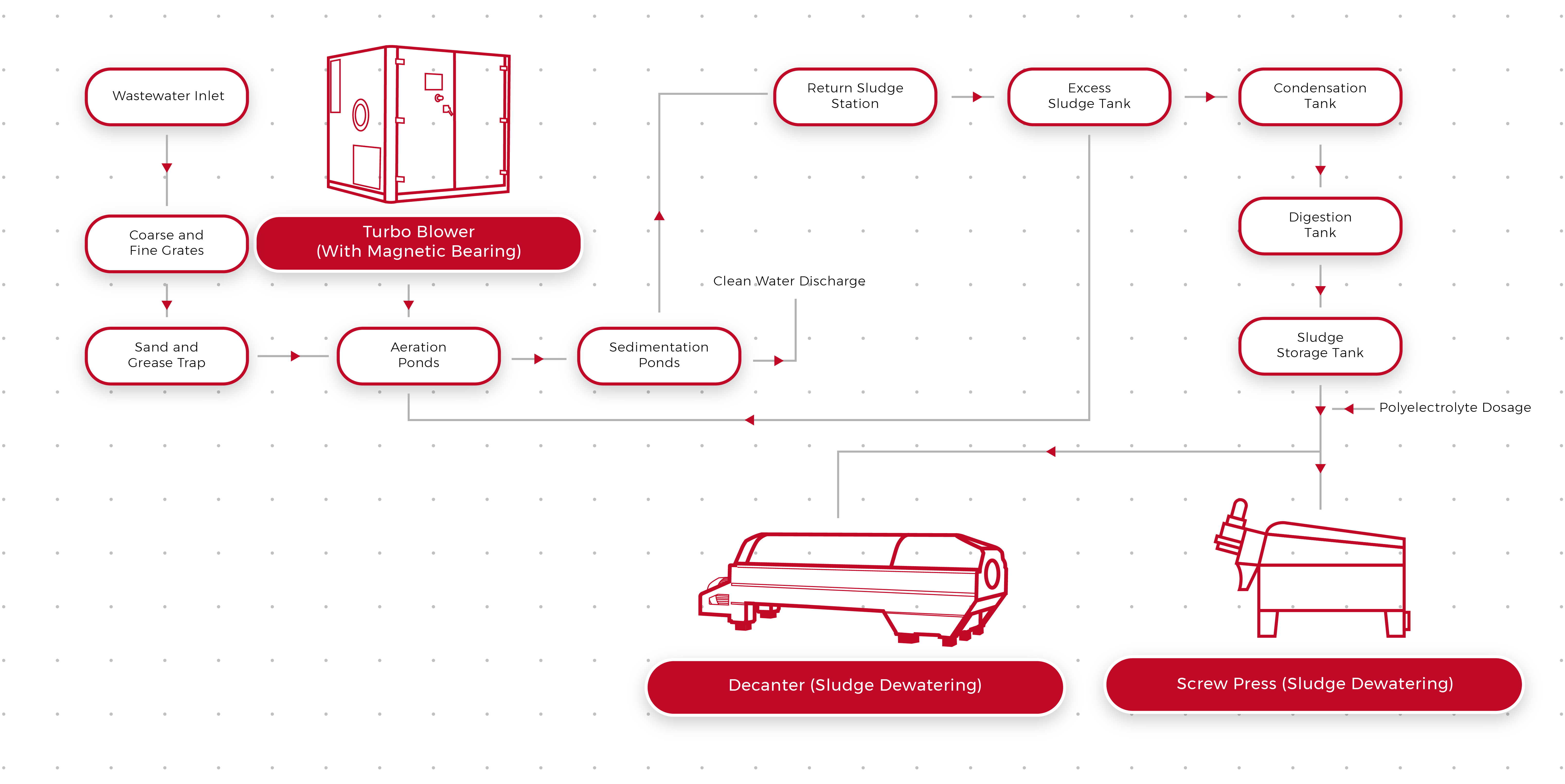

While the plants vary depending on the project in general they are designed to include stages such as coarse grid, fine grid, sand arrestor, oil catcher, lifting station, nitrogen phosphor elimination tank (biophosphor), aeration tanks, settlement tanks, distribution structures, sludge concentration units, digesters, sludge dewatering units, disinfection unit and odor elimination units.

SZ turbo blowers are employed in sand arrestor, aeration tank, sludge tanks and stabilization tanks of treatment plants. Nearly 50-60% of the overall power consumption of a treatment plant is used by blowers. Therefore, blowers are among the most significant and technological equipment pieces in a waste water treatment plant and they impact the plant operating costs significantly.

SZ decanters and screw presses are employed in sludge concentration and/or dewatering stage which is generally the final stage of waste water treatment plants and used for solid and liquid separation. Elimination of sludge has critical importance for ensuring continuity of the plant. Sludge elimination constitutes nearly 25-30% of waste water treatment plant investment and 45-60% of the operating costs. Selection of adequate dewatering equipment and process optimization are very important for minimization of costs.

SZ Centrifuge Technologies employs decanters and screw presses for primary sludge (PS), activates sludge (WAS), extended aeration advanced activated sludge, aerobic / anaerobic digested sludge, MBR sludge produced in municipal waste water treatment plants.

Concentration Process: It is used for increasing the solid matter content of the sludge which is approximately 1-3% to the levels of 6-8%. Concentrated sludge is then fed to dewatering decanter or digester.

Dewatering Process: Decanter or screw press is used for dewatering of primary or secondary sludge.

SZ Centrifuge Technologies turbo blowers are used for supplying air needed in sand arrestor, aeration tank, sludge tanks and stabilization tanks with a polytrophic efficiency up to 84% and an extensive operating range.

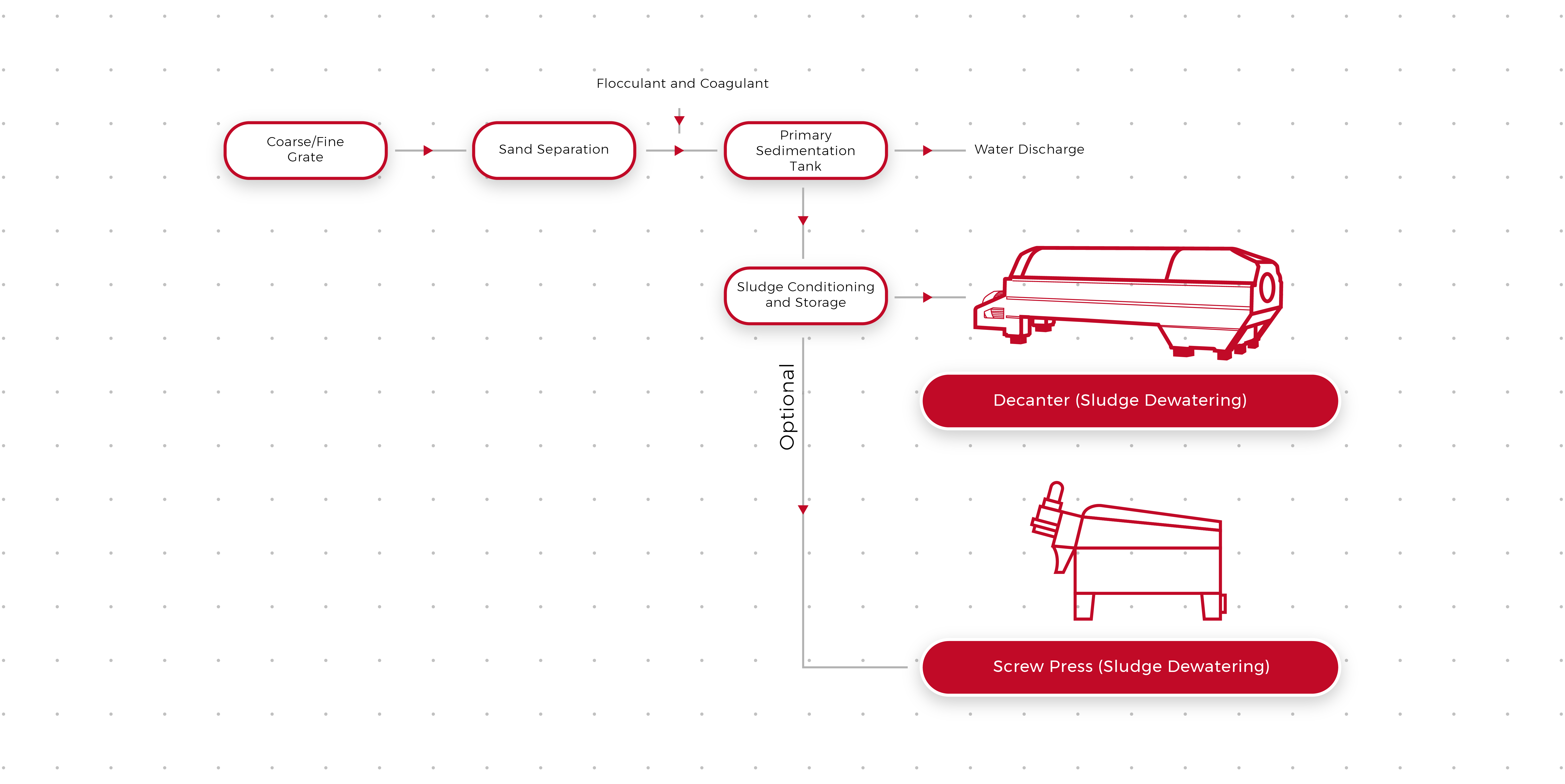

Presedimentation tank contains settling / separable coarse particles.

Has an average solid matter content of 2-4% and volatile solid matter content of ̴ 80%. Feeding of sludge to the dewatering

equipment is performed from sludge conditioning and storage tank.

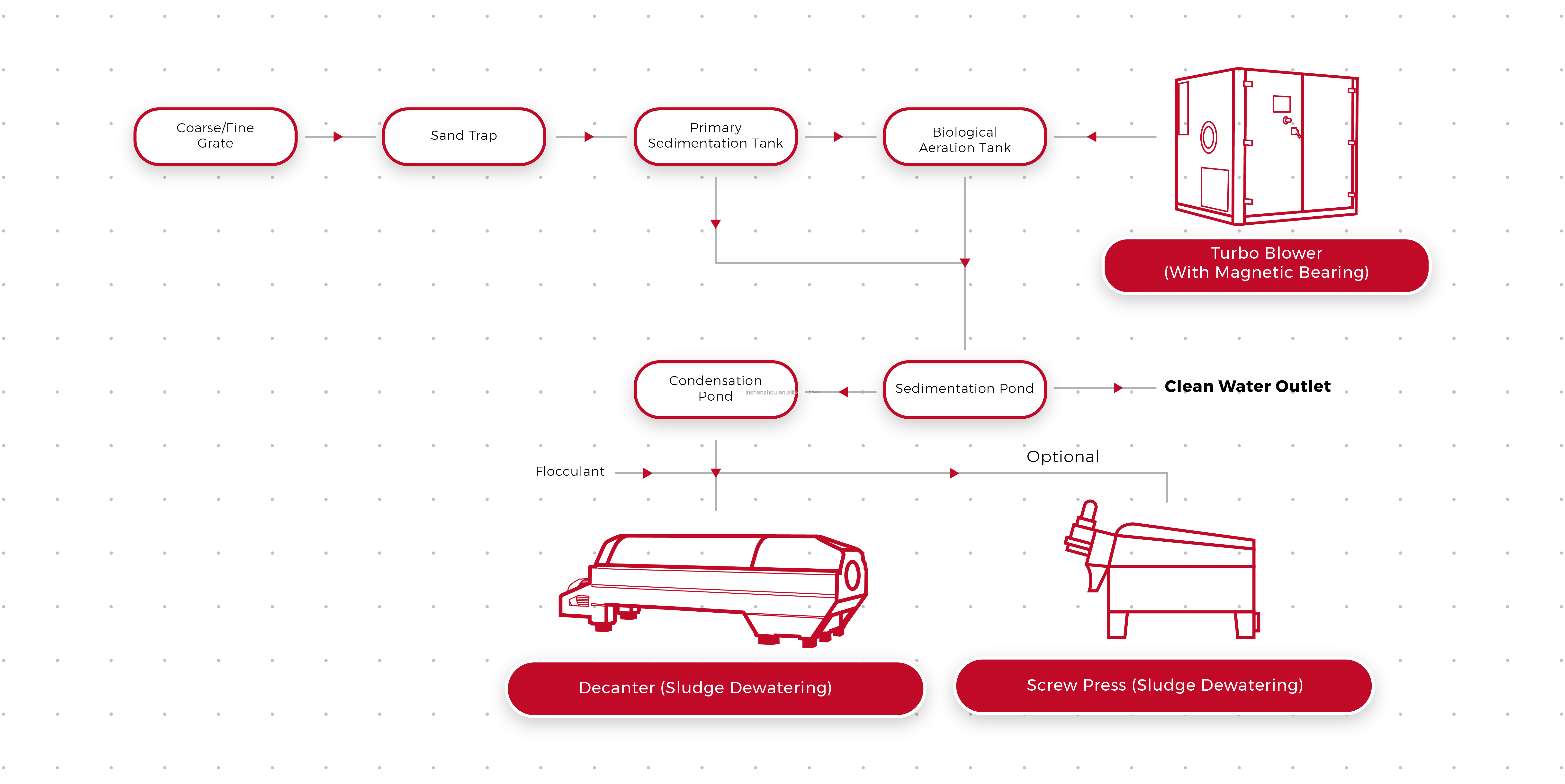

WAS is produced through growth of heterotrophic microorganisms in the activated sludge process.

It has an average solid matter content of 1.0-1.5%. It has a volatile solid matter content of ~75%. Feeding of sludge to the

dewatering equipment is performed from concentration tank. Turbo blowers are used for supplying the needed air to the biological aeration tanks.

When anaerobic conditions are satisfied biogas can be produced from the organic matter content of the waste water. These plants can also generate electrical energy.

Separation of organic matter content of waste water in anaerobic environment consists of two stages. Acid bacteria of organic matters are converted into organic acids, alcohol and CO2 through hydrolysis and acid fermentation.

It includes transformation of the products generated through reaction of acid bacteria to methane, CO2 and water by methanogens.

High calorie methane gas is generated with the process and it can be used as an energy source.

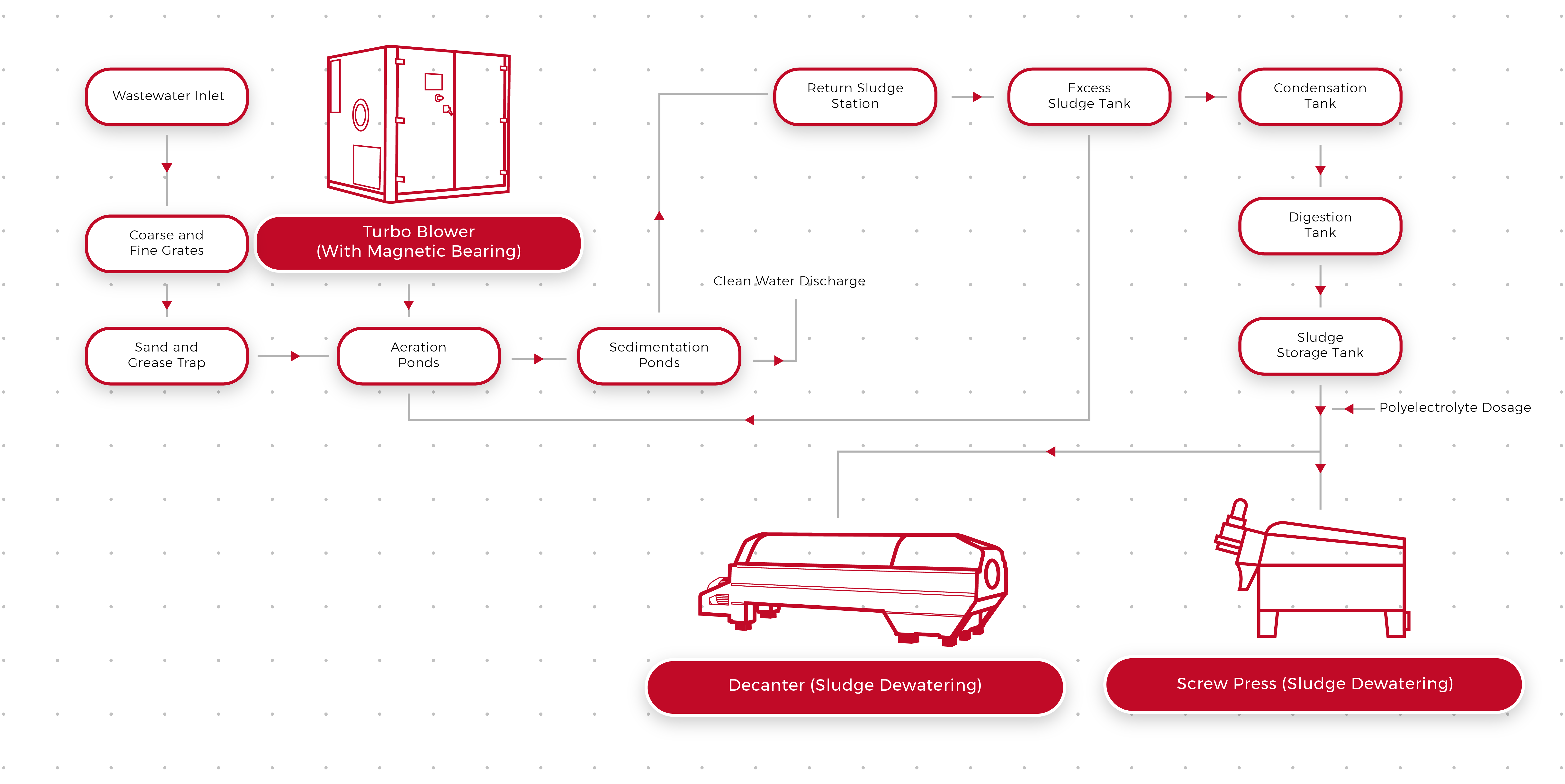

No sufficient substrate is present for microorganisms due to extended retention period of the waste water. Therefore,

microorganisms enter into endogenous respiration by competent each other and consume their own cells. This causes increase in effluent quality. An oxygen concentration lower than 1 mg/L inhibits the nitrification bacteria. optimum pH range is 8-9 for growth of nitrification bacteria. Mineral acidity is produced during oxidization of ammonia to nitrate. pH value of the system is decreased in case of insufficient alkalinity. Optimum dose shall be determined and lime shall be added to keep pH value constant.

Extended aeration process is equivalent to aerobic digestion process.

stabilization of organic sludges.

Aerobic digestion is used in stabilization of treatment sludges with low solid matter content. Nearly 40-50% volatile solid matter elimination is realized in the period of 15-20 days in sludge digestion.

When supply of feed stuff (organic waste-substrate) is ceased in the final digestion stage of the process, microorganisms consume each other to survive causing decrease in solid matter content in the sludge and accordingly, water, CO2 and ammonia is produced.

Ammonia is oxidized to nitrate in the later phase of the reaction.

A flesh processing,aquatic products process and edible protein recovery;

B Extract plant protein from soybean,oily seeds and leguminous plants;

C Recovery of brewing leach liquor malt and yeast

D Treatment and recovery of wine lees liquid;

E Extract of instant coffee and tea;

F Clarification of palm oil,olive oil and seed oil;

G Extract juice from fruits ,berries and vegetables;

H Recovery of refined pectin;

I Clarification of grape juice and grape wine.

2. Environmental protection

Drilling mud ,industrial effluent ,waste water of municipal works,fertilizer,organic waste water,paint sludge,plastic

particles,gravel washing water,waste water in steel-making ,flue gas desulfurization,sewage sludge treatment of waterworks.

3. Petroleum and chemical industry

A Processing of kaolin and calcium carbonate,production of bentonite and titanium dioxide;

B Exploration of petroleum oil,natural gas,crude oil refining and related industries,additive of lube oil and waste oil recovery;

C Intermediate products and final products of organic chemistry industry;

D Thermoplastic materials,includes PVC,polypropylene,polystyrene,synthetic rubber and fiber;

E Inorganic chemical industry ,includes bleach,acid,silica products and fertilizers;

F Treatment of spent wash and molasses fermentation residues;

G Extraction of starch from wheat,corn ,cassava and potato;

H Waste liquid recovery and recycling from above industries.

Other fields

Pharmaceutical intermediates,salts and manures,etc.

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

General Description of Waste Water Treatment Centrifuge

For water purification plants, sewage treatment plants, high-performance water treatment dedicated decanter centrifuge is an ideal solution; it highly adapts to the sludge features, but also has a greater process capacity to handle at low concentrations (SS 0.5 %) case without thickener / concentrator to meet the process aim of concentration and dewatering.

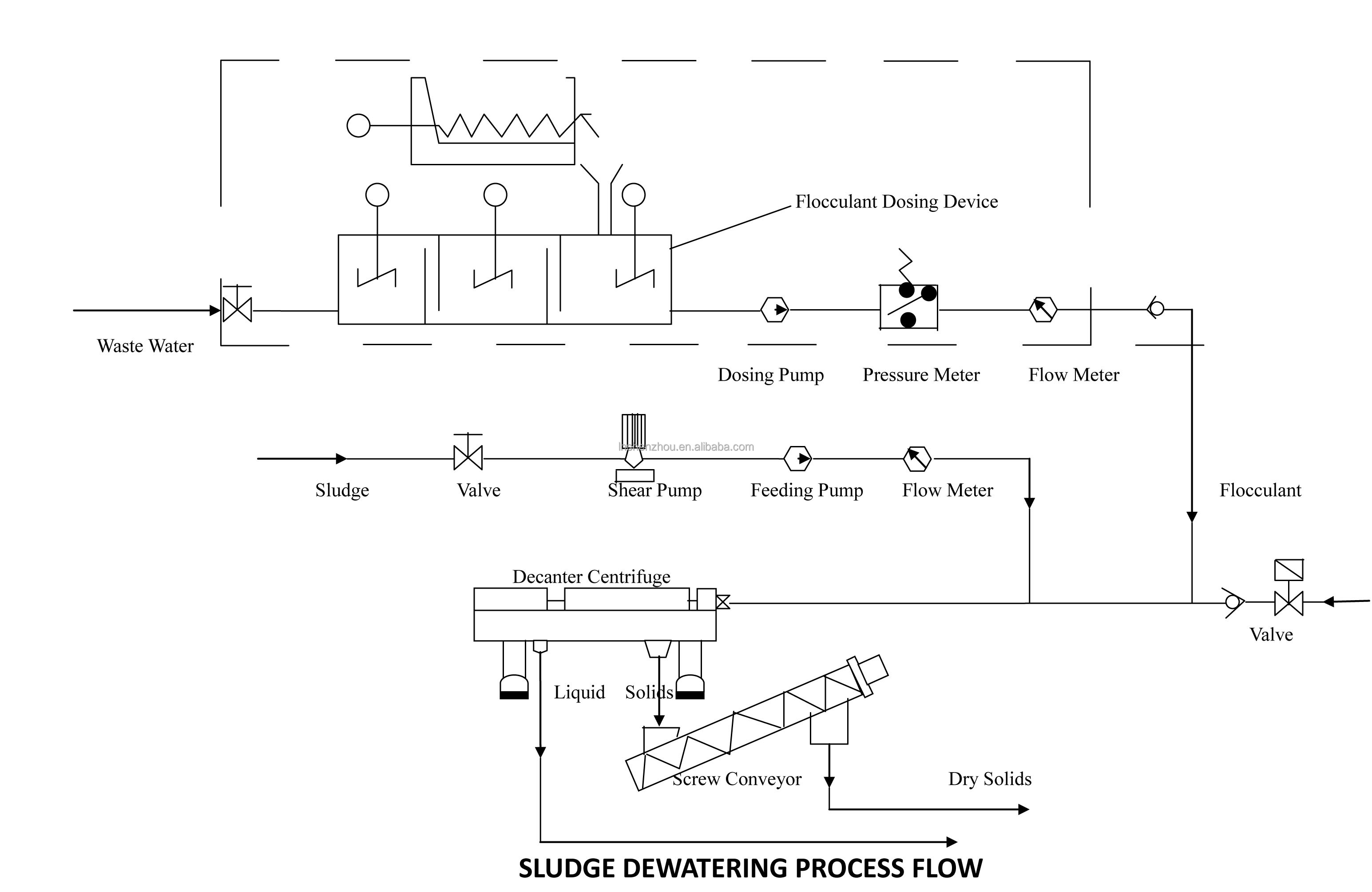

Process Description

The remaining sludge from the sludge pit (primary sediment, secondary sediment) going though the shear pump which smash the glass, plastic bags. The feeding pump feed the sludge (concentration 0.5 ~ 4%, or higher) into the centrifuge, at the same time, dosing pump is automatically dosing flocculant (concentration 1 ~ 3 ‰) into the pipeline. Therefore, the sludge turned to be pellet floc before enter the centrifuge. After the separation of the centrifuge, the dewatered mudcake is discharged from the drum and discharged to the outside through a screw conveyor. The dewatering system is widely used in municipal wastewater treatment such as oxidation ditch, AB, A / O, A2 / O, SBR and MBR processes as well as traditional sewage treatment processes.

Featurers:

1. Water content in dewatered solids: 65%-81%

2. Solids content in liquid after separation: lower than 0.05~0.2%

3. Solids recycle rate: no less than 85%~98%

4. Chemical consumption per ton dry solids: 1~5kg/TDS

Our Centrifuge Application Scope: chemistry; pharmacy; biotechnolog; food and beverage industry; animal fat and regenerative fuels ; wastewater; oil sludge; phytoextraction, extraction,

2)When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.

3)After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force, the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum,the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.

4)The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Following allocation can be possible to meet customer's demand

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Screw production1

Screw production2:

High speed dynamic balance detection1

High speed dynamic balance detection2

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.