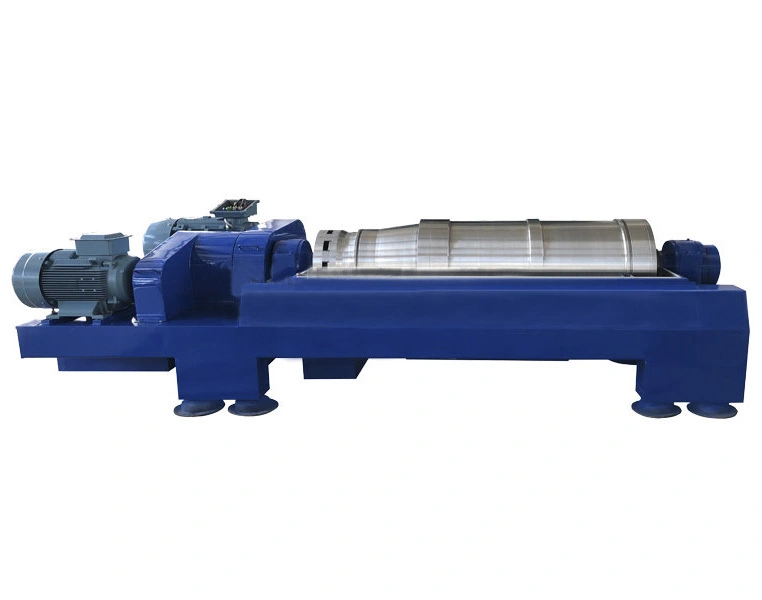

Shenzhou - SZ SEPARATION Decanters for Coal Tar Recovery Process Centrifuge & Separator

Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd In-depth analysis of the actual needs of target customers, combined with its own advantages resources, successfully developed SZ SEPARATION Decanters for Coal Tar Recovery Process. SZ SEPARATION Decanters for Coal Tar Recovery Process enables the company to have more market share, stronger competitiveness and higher visibility. In the future, Shenzhou Group Co.,Ltd/Liaoyang Shenzhou Machinery Equipment Co.,Ltd will continue to attach importance to the cultivation of talents, continuously improve the staff's business level and professional skills, strengthen technological innovation, and continuously enhance the comprehensive competitiveness of the company, in order to achieve'building a century-old evergreen enterprise and creating a well-known international brand' Work hard for this grand goal.

| Place of Origin: | China | Type: | Centrifuge |

| Product Type: | Plant | Condition: | New |

| Video outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty of core components: | 1 Year |

| Core Components: | PLC, Bearing, Gearbox, Motor | Brand Name: | Shenzhou |

| Voltage: | 380V/50HZ,3Phase | Power: | Model |

| Weight: | 1050 | Dimension(L*W*H): | Model |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Food & Beverage Shops, Chemical plant, pharmaceutical plant | Showroom Location: | Thailand, Sri Lanka |

| After-sales Service Provided: | Field installation, commissioning and training |

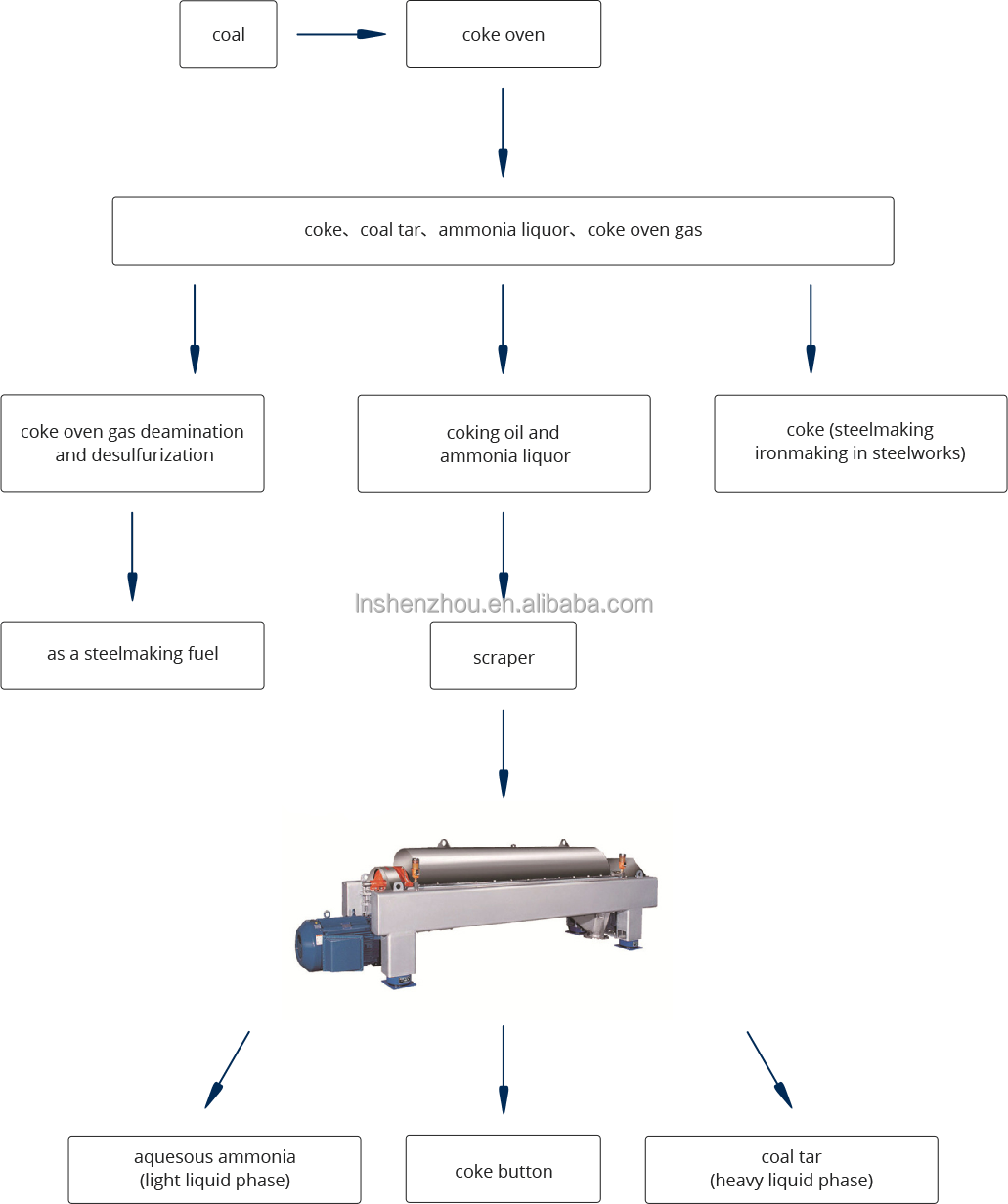

As a by-product of coke and gas produced by coking plants, coal tar has absolute practical value in industrial and medical

industries. In the tar extraction process, dehydration and solid removal effects will directly affect the purity of tar. The

purity of tar will directly affect its market value.

Coal tar is a dark brown, viscous liquid produced when the coal is distilled off. The yield rate of coal tar is usually at 3-4% of the dry coal. According to different coking temperatures, coal tar can be divided into high-temperature tar, intermediate

temperate and low temperature tar. According to different pyrolysis temperate, it can be divided into low temperature (450 ℃ ~ 650 ℃) dry distillation tar, low and medium temperature (600 ℃ ~ 800 ℃) furnace tar, Medium temperature (900 ℃ ~ 1000 ℃) vertical coal tar, high temperature (1000 ℃) coking tar. The crude tar is produced by the coking process with circulating ammonia spray gas and condensate cooling in the primary cooler, containing about 4% water, and sometimes up to 8 to 10%.

The heavy liquid phase separated by the centrifuge can adopt two different liquid discharging modes, namely gravity discharging and discharging through the built-in centripetal pump with pressure, wherein the latter includes liquid layer fixed mode and the online adjustable mode of heavy phase liquid layer, which is selected according to the process conditions.

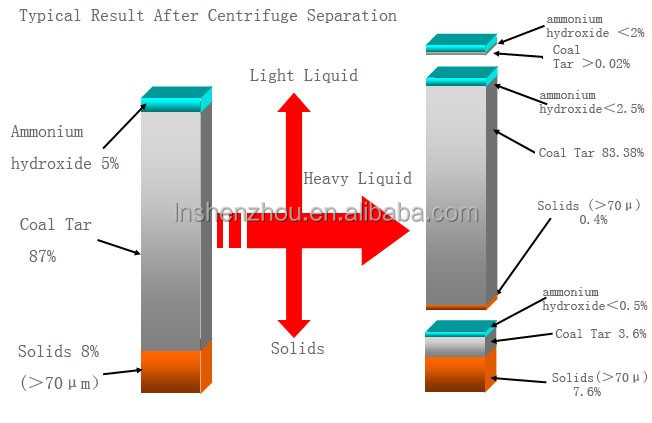

★ Separation performance (typical medium and high temperature coal tar) of coal tar three-phase centrifuge:

1. The centrifuge features high separation efficiency, compact structure, and continuous operation. The diameter of the separated particles can be reduced to 2 μm. The solid content (toluene insoluble matter) in the treated coke button is more than 45%, which can easily optimize the clarification of liquid and the dryness of solids.

2. Tar quality after separation: aqueous ammonia content: <2.5%; tar content: ≥97%; solid content (> 100 μm): <0.3%

3. After separation, the tar in the aqueous ammonia: ≤ 4g/L

Note: The aforementioned separation performances are based on coal tar temperature of 270°C.

★ Three-phase centrifuge model and technical parameters

Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension (mm) |

LWS355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

LWS355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

LWS450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

LWS500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

LWS550*2000 | 550 | 2000 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

LWS650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

LWS650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490*1510*1720 |

2. Tar quality after separation: aqueous ammonia content: <2.5%; tar content: ≥97%; solid content (> 100 μm): <0.3%.

3. After separation, the tar in the aqueous ammonia: ≤ 4g/L.

2)When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.

3)After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force, the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum,the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.

4)The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Following allocation can be possible to meet customer's demand

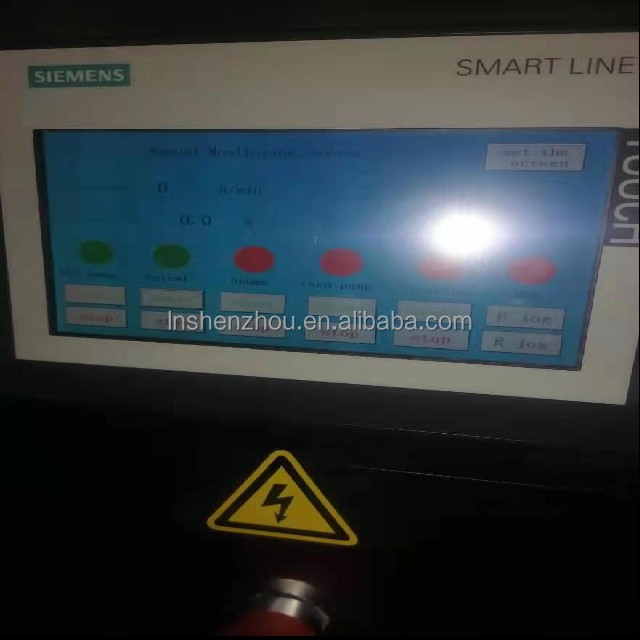

1.Frequency conversion plus PLC controlling system

2.Protection system for vibration and temperature rising

3.Feeding speed control

4.Gas-liquid separation device on liquid outlet

5.Three kinds of structure selection of cycloid gear,planetary gear and hydraulic differential. They are used to be transfered the different solid phase by pushing the torque.

Screw production1

Screw production2:

High speed dynamic balance detection1

High speed dynamic balance detection2

A:1) More than 50 years experience of centrifuge & separator production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use famouse good quality materials and the best production process

Q2.What's the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty period ?

A:12 months.

Durable

Easy Operation

Lubrication Ways

Safety and Security