Batch centrifuge

G series intermittent centrifuges have strong applicability to material properties. They are widely used in solid-liquid separation in sugar, chemical, food, pharmaceutical, environmental protection and other industries. In industrial sugar making, this series of centrifuges are used for refined sugar, white sugar and raw sugar.

Product Overview

Sugar centrifugal machine

Automatic Sugar Separation Centrifuge is a full-automatic equipment with top suspension mechanical scraper discharge.It separates sugar and molasses under the action of centrifugal force field, scrapes the sugar from the basket wall through the radial and axial movement of scraper, and completes the unloading process.The centrifuge equipment is equipped with water washing and steam washing devices,which can wash the materials fully and meet the needs of sugar making process.

This kind of centrifuge can also be used to separate materials with fine solid grains, high viscosity, good fluidity, compact texture and difficult to unload by gravity. Generally, the solid-liquid ratio (weight ratio) of suspension is 40 ~ 60%.such as used for separation of glucose, xylose (alcohol), maltose (alcohol), mannitol, fructose, monosodium glutamate.

FEATURES AT A GLANCE

Features

Compact designs

Automatic operation and easy to start

Step-less speed control with stable working

Low moisture after from the machine

Supporting self-cleaning

Less noise with high performance damper

PRODUCT CONFIGURATION

Working principle.

When the basket rotates at high speed, it will produce a centrifugal force thousands of times greater than its own weight, so that the sugar paste on the basket wall is subjected to the centrifugal force, and the granulated sugar crystal are intercepted in the basket by the screen to form a filter layer,Under the action of centrifugal force,

molasses will pass through the filter layer and screen, and finally flow out of the basket hole wall to complete the separation of crystal and mother liquor.

The primary sugar paste separation can be divided into four stages: sugar layer formation stage, centrifugal molasses removal stage,molasses washing stage and drying(separating) stage.

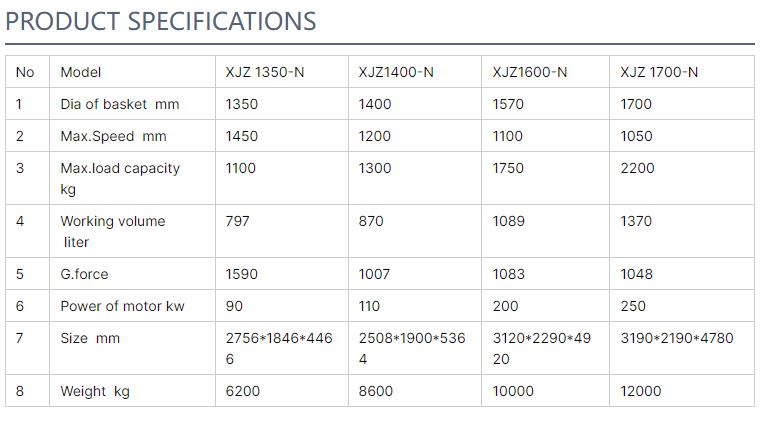

Technical Parameters: