How to select a suitable decanter centrifuge for activated sludge separation

Key indicator: Based on the daily dry sludge treatment capacity (tons/day), convert the actual treatment capacity combined with the sludge moisture content.

Example: Sludge with a moisture content of 97%, 100 tons of wet sludge corresponds to 3 tons of dry sludge (dry basis).

Moisture content: The higher the initial moisture content (such as 99%), the model with higher separation efficiency (such as high rotational speed and large length-diameter ratio) should be selected.

Particle size and viscosity:

Fine particles (such as activated sludge microbial flocs) require higher centrifugal force (rotational speed ≥3000rpm);

High-viscosity sludge (such as digested sludge) needs to be matched with a conditioning process (such as adding lime) and select equipment with anti-blocking design.

Organic matter content (VSS/SS):

When VSS/SS ≥0.7, the sludge is prone to decay and difficult to dewater, requiring enhanced centrifugal force or extended residence time (differential speed ≤10rpm).

Length-diameter ratio (L/D):

3.5–4.5 is recommended. The larger the length-diameter ratio, the larger the sedimentation area, which is suitable for fine-particle sludge (such as activated sludge).

Drum rotational speed and centrifugal force:

Activated sludge separation requires a centrifugal force of 2000–5000g (corresponding to a rotational speed of 2500–4000rpm). The higher the rotational speed, the lower the moisture content of the sludge cake, but energy consumption and equipment wear need to be controlled.

Differential speed adjustment range:

A differential speed of 5–30rpm is recommended, and it should have a frequency conversion adjustment function to adapt to different sludge properties (such as low differential speed for high-viscosity sludge).

2. Material and Anti-Corrosion Design

Materials of contact components:

Ordinary activated sludge: 304 stainless steel;

Acidic sludge (pH <5) or with corrosive substances: 316L stainless steel or duplex steel (such as 2205);

Scenarios with severe wear (such as sand-containing sludge): Tungsten carbide coating on the surface of the screw pusher.

3. Automation and Control Functions

Necessary functions:

Frequency conversion speed regulation (real-time adjustment of rotational speed and differential speed);

Fault early warning (vibration, temperature, torque monitoring);

Linked control with the flocculant dosing system (such as automatically adjusting the chemical dosing amount according to the feed flow rate).

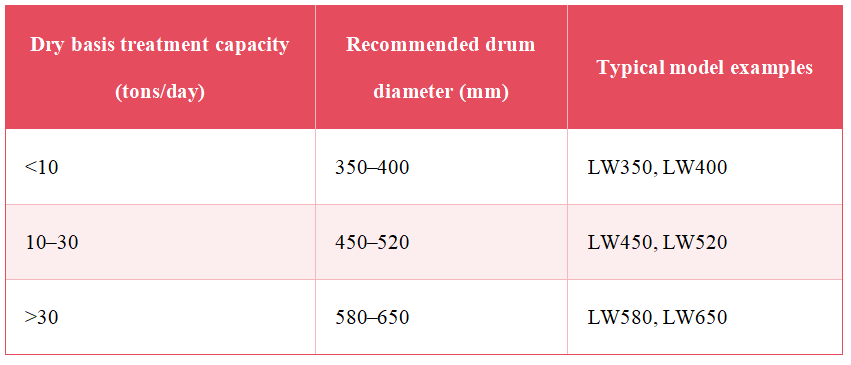

|  |

III. Process Matching and Auxiliary Systems

1. Pretreatment Process Adaptation

Flocculant dosing system:

It needs to match the centrifuge treatment capacity. For example, if treating 10 tons of dry sludge per day, the PAM dosing amount is calculated at 5kg/ton of dry sludge, and a dissolution tank with a concentration of 0.1%–0.3% and a metering pump need to be configured.

Conditioning equipment:

Digested sludge needs to be matched with a lime dosing system (dosing amount 5%–10%), and it is necessary to confirm whether the centrifuge has an alkali-resistant design (pH ≤12).

2. Post-Treatment Requirements

Target moisture content of sludge cake:

If it needs to be reduced to below 60%, a model with high rotational speed (≥3500rpm) + small liquid ring thickness (≤30mm) should be selected;

If it is used for anaerobic digestion, a moisture content of 75% is sufficient, and the rotational speed can be reduced to save energy.

Reuse of separated liquid:

If the separated liquid needs to be recycled to the wastewater treatment system, equipment with high separation precision (SS ≤500mg/L) should be selected.

IV. Economic and Site Considerations

1. Energy Consumption and Operation Costs

Power calculation:

Model with a drum diameter of 450mm: Power is about 30–45kW, and the energy consumption for treating 1 ton of dry sludge is about 8–12kWh;

Compared with traditional belt filter presses, decanter centrifuges have 10%–15% higher energy consumption but 20%–30% lower chemical costs.

Site requirements:

A single LW520 centrifuge occupies about 4–6㎡, and supporting facilities (chemical rooms, control cabinets) require an additional 5–8㎡, which is suitable for scenarios with tight site space.

2. Suppliers and Services

Preferred choices:

Brands with cases in the wastewater treatment industry (such as German Flottweg, Swedish Alfa Laval, domestic Haishen Electromechanical, etc.);

Provide equipment debugging, operator training, and regular maintenance services (such as suggestions for replacement cycles of worn parts).

V. Selection Case Reference

Scenario: Municipal Wastewater Treatment Plant (Treatment Capacity 50,000 Tons/Day, Excess Sludge Moisture Content 97%)

Dry basis treatment capacity calculation:

Wet sludge volume: 50,000 tons/day × 3% (dry basis proportion) = 1,500 tons/day of wet sludge, corresponding to 45 tons/day of dry sludge.

Equipment selection:

Select 2 sets of LW520 decanter centrifuges (single-unit treatment capacity 25–30 tons of dry sludge/day), drum diameter 520mm, rotational speed 3200rpm, length-diameter ratio 4.0;

Material 316L stainless steel, equipped with an automatic PAM dosing system (dosing amount 5kg/ton of dry sludge).

Expected effects:

Sludge cake moisture content 70%–75%, separated liquid SS ≤300mg/L, energy consumption of a single unit is about 40kWh/hour, and operating costs are reduced by 15% compared with belt filter presses.

VI. Avoidance of Selection Mistakes

❌ Selecting only based on wet sludge volume: The dry basis treatment capacity should be the core to avoid equipment overload (such as mistakenly taking 100 tons/day of 97% moisture content sludge as the dry basis treatment capacity).

❌ Ignoring sludge changes: If the wastewater treatment plant may accept industrial wastewater in the future, reserve space for equipment parameter adjustment (such as rotational speed adjustment range ≥2000–4000rpm).

❌ Neglect after-sales maintenance.: Failing to require suppliers to provide replacement cycles and costs for vulnerable parts (such as screw pushers and seals), leading to a surge in later operation and maintenance costs.

Through comprehensive evaluation of the above dimensions, it can be ensured that the selected decanter centrifuge achieves the optimal balance of efficiency, cost, and stability in activated sludge separation.