Disc Centrifuge vs. Decanter Centrifuge - Which is Better for Food Processing

Today's world is running behind high productivity and precision. The food industry here is no exception. People are using modern technology to ensure a better quality of food. Additionally, consistency, quality, and speed are also essential factors to consider. Regarding popular devices, disc centrifuges, and Decanter centrifuges are the two most commonly used types.

Both food industry centrifuges come with unique purposes. In this article, you will learn more about it. Ultimately, you will know which one to choose.

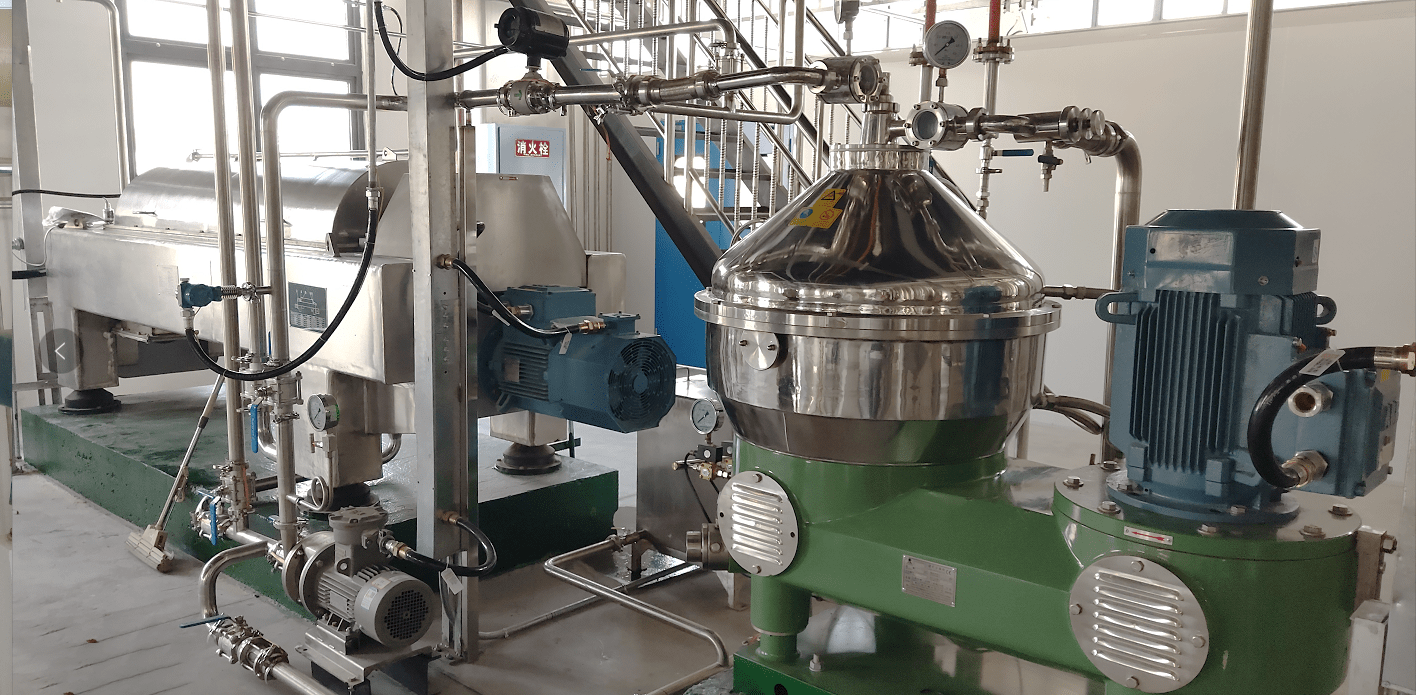

What is a Disc Centrifuge Separator?

As the name implies, it is a machine that separates food materials. In most cases, it separates the solids and liquids from a mixture. However, you can also use it to separate two types of liquids of different densities. Some disc centrifuges can even perform three-phase separation. For example, you can separate solids, light liquids, and heavy liquids, all in a single run.

The machine typically works using a stack of cone-shaped discs. When the mixture enters, centrifugal force causes the heavier particles to move outward. Thus, the name is disc centrifuge separator.

During the process, the clean liquid rises to the top, and solid particles collect at the edge of the bowl. You can typically consider this device for food items with low solid contents. It's best when you need high clarity. Typical examples include clear juice or purified oil.

What is a Decanter Centrifuge Separator?

A decanter centrifuge, on the other hand, is another type of separator. The construction, capacity, and functions differ significantly from those of the disc centrifuge separator. It typically features a horizontal setup with a long and cylindrical bowl.

Inside the bowl, you will find a rotating screw conveyor. As the entire unit spins, the internal screw typically separates the solid from the mixture. It pushes the solid materials at one end, leaving the liquids behind.

A decanter centrifuge is typically ideal for high-volume applications. It can easily tackle thick, dense, and challenging feedstocks. You can use it to process mashed fruit, vegetable pulp, and fermentation residues.

Disc Centrifuge Vs Decanter Centrifuge: Which is Better for Food Processing?

Both the food industry centrifuges are renowned. Their unique purposes and construction make them ideal for different applications. In the following few sections, you will go through each point. You will discover their core differences and understand which one is better suited for what. Let's break it down by category.

1 Centrifuge Orientation

Disc centrifuge separator has a vertical orientation and is often compact. Unlike the decanter centrifuge, this food industry centrifuge doesn't take up much space. It is ideal for limited floor space. If you are looking for more flexibility in food processing, you may want to consider this type. Whether you are working with dairy, tea, or juice processing, this food industry centrifuge offers a broader range of facilities.

How about a decanter centrifuge? It features a horizontal setup and requires additional space for installation. This type of food industry centrifuge is typically suitable for large-scale plants. You may consider this type of food industry centrifuge for fruit pulp extraction or handling sludge. It is often seen in the beverage or starch industries.

2 Separation Efficiency

The disc centrifuge separator uses multiple conical discs. This unique structure typically creates thin separation layers. Thus, it's ideal for achieving high-clarity results. Therefore, the disc centrifuge separator is excellent for clarifying edible oil, beer, or wine. The average efficiency of a disc centrifuge separator is down to 0.5 microns per level. Additionally, it offers a 1-micron level for both organic and inorganic particles.

The decanter centrifuge, on the other hand, focuses on volume over finesse. This food industry centrifuge is ideal for rough separations. If you can accept some residual particles, this device is an excellent tool. Thus, it works great in vegetable pulp dewatering or initial sludge separation. The efficiency level of a decanter centrifuge ranges from 50 microns or more.

3 Capacity and Throughput

The disc centrifuge separator can handle fine clarification. However, it is typically ideal for low to medium-volume applications. It's mainly suitable for applications that need frequent product changeovers. The best examples include juice clarification and milk skimming. The diameter of a disc centrifuge may range up to 730mm.

How about a decanter centrifuge? It has a continuous solids discharge screw mechanism. This machine is bigger. It is ideal for heavy-duty and high-throughput tasks. Using this device, you can conveniently process high-volume fruit mash, wastewater sludges, or brewery-spent grains.

The size of a decanter centrifuge may range from 1,790 x 1,080 x 640 mm to 6,000 x 2,700 x 1,500 mm. The weights range from 900 kg to 14,000 kg. The capacity ranges from 0.5 to 190 m3 per hour. Depending on your production volume, you can select the most suitable option for your project.

4 Allowable Feed Solid Concentration

Allowable feed solid concentration refers to the maximum quantity of solid content in a mixture that a centrifuge can handle. In this case, both the disc and the decanter centrifuge differ significantly.

A disc centrifuge separator typically has a fixed sludge holding space. Because of this, it can operate best with light suspensions. The allowable feed solid concentration for the disc centrifuge is up to 5%.

On the other hand, decanter centrifuges offer you more. It typically allows up to 50% feed solid concentration.

5 Power Ratings

The disc centrifuge separator spins at high RPMs but processes a low volume. Because of this, this food industry centrifuge is ideal for energy-efficient applications. Typically, this type of device requires power ranging from 1.5 to 5 horsepower.

On the other hand, the decanter centrifuge is larger. It typically handles large volumes of materials. The power ratings of these devices range from 50 HP to over 500 HP.

6 Phase Separation Capabilities

Phase separation is one of the most crucial factor that significantly differ these two food industry centrifuge machines. Phase separation refers to the number of elements that a centrifuge can separate.

The disc centrifuge separator can separate solid, light and heavy liquid all in one cycle. On the other hand, decanter centrifuse mainly separates solid and liquid. However, a decanter centrifuge may also feature three-phase capabilities. It is crucial to note that there is a significant difference between these two types, particularly in terms of cost and efficiency analysis.

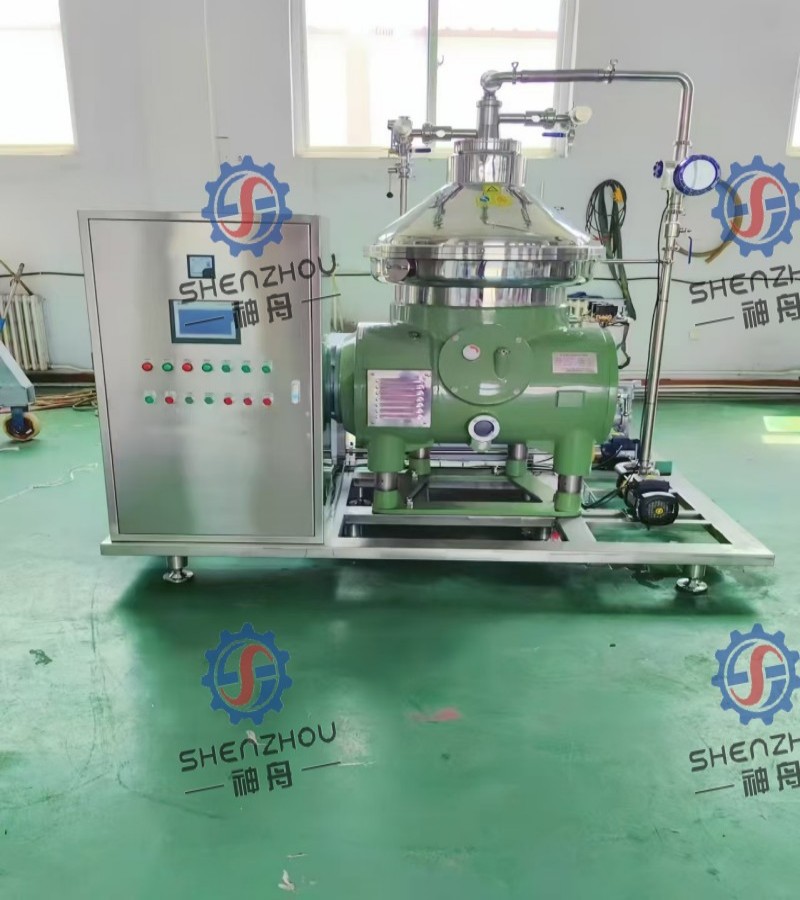

Why Choose Shenzhou Machinery ?

At Shenzhou Machinery we specialize in various types of food industry centrifuge systems. Whether you're a dairy processor or a beverage manufacturer, they've got a tailored solution. You might be wondering why us?

(1) Shenzhou Machinery offers custom-engineered solutions to match your production lines.

(2) Most containers or cylinders used in these machines are made of high-quality, food-grade stainless steel. The company ensured a hygienic design for food compliance.

(3) Their machines are available with installation, commissioning, and training packages.

Above all, if you have any questions, feel free to reach our customer support team.