How do you Choose a 2-phase and 3-phase Decanter Centrifuge Lab?

Deciding on a decanter centrifuge for laboratory use, particularly among 2-phase and 3-phase centrifuges, calls for a deep understanding of the lab's desires. This relies on the knowledge to be processed, desired efficiency, area constraints, and budget. 2-phase decanter centrifuges are versatile because they separate solids from liquids without problems. But, 3-phase models, which separate immiscible beverages and solids, are exceptional for complex separations. This guide provided the necessary information regarding decanter centrifuges and their basic features, workings, and evidence comparison.

2 Phase Decanter Centrifuge

Two immiscible liquids or a liquid and solid can be separated using the two-phase centrifuge. The separation happens automatically and in real-time, without human intervention. Environmental protection, sewage treatment, the chemical industry, food processing, fermentation, medicine, and mining metal and non-metal minerals are just a few of the many applications for two-phase centrifuges.

When the solids content of the suspension needs processing and is exceptionally high, the decanter centrifuge comes into play. High clarifying efficiency, maximum dewatering, and the ability to separate liquids while removing solids simultaneously are all features of these decanter centrifuges. In 2 phase decanter centrifuge, a high bowl speed, a strong scroll drive, and an automatically adjustable scroll speed in response to feed solids loading are essential. The decanter centrifuge's adaptability and the technical expertise of the Huading Separator make it suitable for a wide variety of process operations, including clarification, separation, classification, concentration, washing, and extraction.

|

|

Workings Of 2 phase Decanter

A sample is fed into the 2 phase decanter centrifuge using a conveyor and an intake pipe. The sample is transferred to the bowl using a nozzle after being fed through an internal feed compartment using the conveyor. The next step is to generate centrifugal forces by spinning the bowl rapidly. Using high-speed rotation, the solid substance is separated from the liquid in a few seconds. Remember that the solid material is conveyed up the conveyor and discharged through a nozzle. After the solids are extracted, a separate output from the 2 phase decanter centrifuge releases the liquid that has been purified.

Benefits and Features

● Very little time spent processing

● Diluted water is almost nonexistent

● Consumption of less energy

● Absence of sludge tanks and vertical clarifier

● Reduced in size ponds - significantly decreased emissions of methane

● An increase in output

● Utilization of nutrients for recycling

● Fertilizer made from organic sources increases FFB output.

3 Phase Decanter Centrifuge

The three-phase decanter centrifuge is one common piece of machinery for separating solids, heavy, and light liquids based on specific gravity differences. 3 Phase Decanter Shenzhou Machinery Separation is one manufacturer offering a three-phase decanter centrifuge based on over a decade of practical experience. This machine is used in many modern industries, including oily sludge, slaughterhouse wastewater, kitchen waste, oil clarification, fish products, wheat starch production, etc.

The use of three-phase separation technologies is rising in the separation industry. When it came to separating oils and water, the industry particularly needed high-efficiency three-phase decanter centrifuges. Shenzhou Machinery Company has over 50 years of experience in the separation field, which they used to develop the 3 Phase decanter centrifuge. Its primary use is in solving the problem of simultaneous immiscible liquid and solid phase separation using the specific gravity difference. The need for stable, continuous operation around the clock can be met by the 3 Phase decanter centrifuge thanks to its mature design and high-quality raw material selection.

|

|

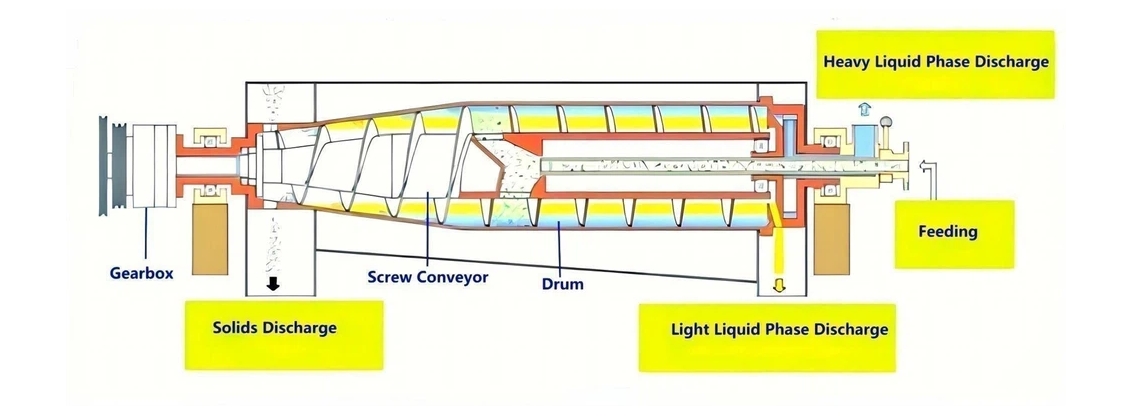

Working of 3 Phase Decanter

The 3 Phase decanter centrifuge has seven main mechanisms that work together as follows: the feeding component, the underframe component, the bowl component, the screw component, the differential gearbox, the drive component, and the collection box component. The feeding component receives the materials to be separated from the conveying system.

The materials then flow into the inner cavity of the bowl, which rotates in synchronization with the bowl. Because of their different specific gravities, the three types of centrifugal forces are as follows: the strongest for solids, the second strongest for heavy-phase liquids (like water), and the weakest for light-phase liquids (like oil). This allows the centrifugal force to work magic, forming an outer solid layer and two inner liquid layers. The solid material that has been deposited on the inside wall of the bowl is moved to the machine's solid outlet using the screw, where it is dried further using extrusion and subsequently released.

Meanwhile, the liquid material flows to the machine's liquid phase outlet and overflows at various points, separating the solid, heavy, and light liquid phases. The Shenzhou Machinery 3-phase decanter centrifuge uses centripetal pump technology to determine the optimal placement of the liquid discharge layer based on the relative proportions of the heavy and light liquid phases and to adjust the position of the neutral layer of these phases. Additionally, the centripetal pump serves as the heavy liquid phase flow outlet, making it an ideal choice for pipeline layout.

Features and Benefits

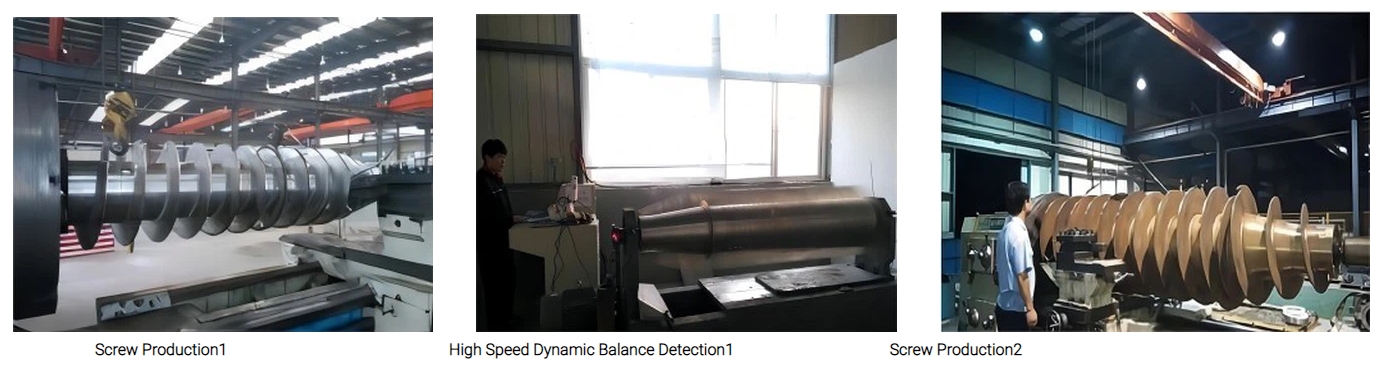

● It has a high precision, compact design, and easy operation.

● The main bearings are imported to guarantee the precision of the operation.

● A stainless steel component makes contact with the material.

● The machine is outfitted with multiple overload protection devices to guarantee production safety.

● The machine system is available in standard and explosion-proof to accommodate various needs.

● Drum cone structure with many angles, large length-to-diameter ratio, and high speed

● Abrasion resistance is greatly enhanced by the use of hard alloy materials on the spiral pusher surface.

● Customers can choose between a low center of gravity, a high bracket, or a mobile frame.

● Concentration dehydration of activated sludge and difficult-to-separate materials is achieved using a spiral structure with a BD board.

Comparison Between 2-Phase And 3 Phase Decanter

The fundamental principles of operation for the 2 phase decanter centrifuge and 3-phase Shenzhou Machinery decanter centrifuges are identical to those of the horizontal decanter centrifuge. To separate substances with different densities, the equipment uses a high-speed rotating assembly to create an acceleration inside the bowl that is thousands of times stronger than gravity. Then, the relative motion between the bowl and the screw is generated by the differential gearbox, allowing for the separation of the substances. In contrast, 3 phase decanter centrifuges use centripetal pump technology to achieve solid-liquid-liquid three-phase separation, as opposed to Shenzhou Machinery 2-phase centrifuges, which are utilized for solid-liquid two-phase separation and discharge the solid slag and separation liquid from an opening at the bottom of the equipment collection box. Under the pressure of the centripetal pump, the heavy liquid phase is discharged through the flow outlet on the impeller. In contrast, gravity sends the solid slag and light liquid phase down from the bottom opening of the equipment collection box.

|

|

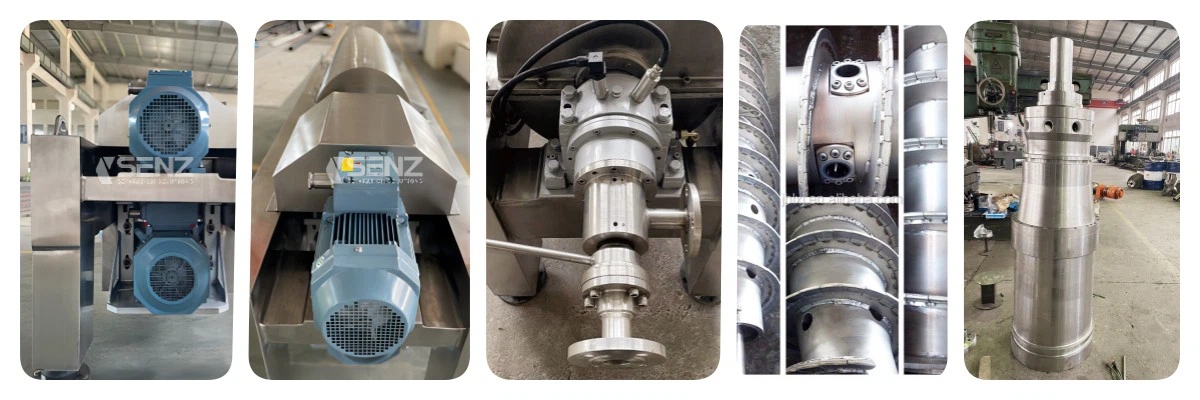

The Shenzhou Machinery is the right pitstop for your machinery purchases. A few of our machines were granted patents for newly invented technologies. An industry leader in the production of centrifuges and so much more. The number of disc separators and decanter centrifuges today exceeds 180 worldwide. So, purchase your refined centrifuge machinery of choice from us TODAY!