Maximizing Oil Recovery: Advanced 3Phase Centrifuge Settings for Biodiesel

Every drop of oil counts in the competitive world of biodiesel. The three-phase centrifuge plays a key role, separating oil from water and solids; a step that’s crucial for producing high-quality biodiesel. When the 3-phase centrifuge is set up just right, it can boost oil recovery, improve purity, and reduce waste. But even small tweaks in the settings can lower yields and drive up costs. How exactly can the right adjustments make every drop of oil count in biodiesel production?

Understanding the Role of the 3-Phase Centrifuge in Biodiesel Production

Three distinct phases can be extracted from a mixed feedstock stream using a 3Phase Centrifuge:

● Oil phase: Raw recovered oil or biodiesel.

● Water phase: Soluble contaminants and remaining water.

● Solid phase: Undesired particles, gums, and sediments.

This separation is essential to producing a high-purity oil phase that satisfies industry standards in the manufacturing of biodiesel. In contrast to conventional two-phase centrifuges, the 3-phase design guarantees more effective impurity removal, lowering the requirement for further filtration.

Better oil recovery can be achieved without reducing throughput, thanks to accurate control over operation parameters. Due to their durability and automated control systems, industrial-grade models, such as the Industrial 3Phase Centrifuge settings for biodiesel production, are advised for high-capacity facilities.

Key Parameters Influencing Oil Recovery

Several adjustable factors directly impact the efficiency of a 3Phase Centrifuge:

● Rotational Speed (RPM): A higher RPM improves separation efficiency, but if it is set too high, it can result in emulsion formation.

● Feed Rate: Higher feed rates increase output at the expense of clarity, whilst slower rates provide better separation.

● Weir Plate Settings: By varying the height of the weir plate, the position of the liquid interface is altered, improving phase separation.

● Bowl Design and Angle: Bowl design and angle have an impact on clarity and settling time.

● Operating Temperature: Operating temperature affects the viscosity of the feedstock, which influences the rate of separation.

● Feedstock Characteristics: Animal fats, soybean oil, palm oil, and waste cooking oil all need different operational changes.

Key Parameters Influencing Oil Recovery

To achieve the maximum performance from a 3Phase Centrifuge, it's essential to understand how each adjustable setting impacts separation results and efficiency.

Below are the most critical factors to keep in mind, along with their functions and possible consequences if not properly maintained. This technique leads to increased total oil recovery and greater purity.

1. Rotational Speed (RPM)

When you increase rotational speed, the centrifugal force becomes stronger. This makes it easier to separate oil from solids and water.

Risk if Not Changed:

When the RPM is too high, it can produce emulsification, which makes it harder to separate. It can also put extra stress on the equipment, which makes it last less long.

2. Effect of Feed Rate on Oil Recovery

A cleaner oil output, with fewer impurities, happens when the centrifuge has more time to separate phases at lower feed rates.

Risk if Misadjusted:

If the feed speed is excessively slow, the efficiency goes down, which lowers the total amount of production. But a pace that is too high could make purity less sure.

3. Weir Plate Height Effect on Oil Recovery

The position of the liquid interface inside the bowl can be controlled by varying the weir plate height. Proper adjustment guarantees the separation of solids, water, and oil in the appropriate zones.

Danger if Not Adjusted:

Phase mixing, in which water contaminates the oil or oil mixes into the water outflow, can be caused by improper weir settings. Recovery rates and product quality are lowered as a result.

4. The Impact of Operating Temperature on Oil Recovery

Oil can separate in the centrifuge more rapidly and efficiently when the proper operating temperature is maintained, since it lowers oil viscosity.

Danger if Not Adjusted:

The quality of biodiesel can be impacted by feedstock degradation caused by too high temperatures. Additionally, equipment stress and safety hazards might result from overheating.

Optimizing Parameters for Different Feedstocks

Because each feedstock used to make biodiesel has distinct physical characteristics, centrifuge settings should be adjusted appropriately:

Waste Cooking Oil

● Higher impurity levels necessitate slightly lower feed rates and higher RPM (within safe mechanical bounds).

● Raising the operating temperature will decrease viscosity.

Virgin Vegetable Oils (e.g., soybean, canola)

● Because there are few contaminants, a lower RPM is frequently adequate.

● Clarity can be maintained while using higher feed rates.

Animal-Based Fats

● Preheating is necessary to lessen solidification.

● Maintain constant temperature management and use a reasonable RPM.

Various Feedstocks

● To maintain separation efficiency, real-time modifications must be made utilizing inline sensors.

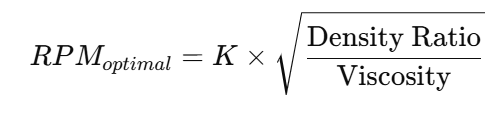

Formula for Optimal RPM Setting:

Where:

● K = machine constant from manufacturer specs

● Density Ratio = Oil density ÷ Water density

● Viscosity = Centipoise (cP) measurement of feedstock

Quick Adjustment Table:

Feedstock Type | RPM Range | Feed Rate | Temp (°C) |

Waste Cooking Oil | 4,500–5,200 | Low | 60–70 |

Virgin Oils | 3,800–4,300 | High | 40–50 |

Animal Fats | 4,200–4,800 | Medium | 55–65 |

Advanced 3Phase Centrifuge Setting Recommendations

Take into consideration these cutting-edge best practices to optimize oil recovery in biodiesel:

1. Start with Manufacturer Settings

Before making changes, start with the factory-recommended values.

2. Method of Gradual Adjustment

To identify ideal points, adjust one setting at a time, track changes, and keep an eye on the oil's purity.

3. Monitoring and Automation

Install PLC-based systems to make real-time parameter adjustments.

4. Weir Plate Adjustment

To maintain the interface precisely, inspect and reset every 50 to 100 running hours.

5. Control of Temperature

For the particular type of oil being processed, preheat the feedstock to the proper viscosity.

Precision Tips

● To prevent emulsification, maintain a steady rotational speed of ±10 RPM.

● When alternating between light and heavy oils, adjust the weir height.

● To find early indications of phase contamination, check the discharge for clarity.

Upkeep and Diagnostics for Reliable Oil Recovery

Poor maintenance can reduce separation efficiency even with the finest settings:

● Regular Cleaning: To avoid accumulation, clean the bowl and disc stack.

● Seal & Gasket Inspection: Inspection of the seal and gasket stops leaks that interfere with separation.

● Vibration Monitoring: Vibration monitoring finds imbalances that lower productivity.

● Check Discharge Quality: Verify the discharge quality; excessive particulates or hazy oil are signs of misaligned parameters.

Troubleshooting Example:

● Problem: Cloudy oil phase.

● Possible Causes: Might include incorrect weir height, too high feed speed, or an RPM that's too low.

● Solution: Calibrate the weir plate again, reduce the feed rate, and gently raise the RPM.

The Bottom Line

One of the fastest ways to boost efficiency, cut costs, and get more oil is by fine-tuning the 3Phase Centrifuge settings for biodiesel production. Operators see better results when they understand how the type of feedstock, temperature, and machine settings work together.

Whether using animal fats, fresh vegetable oil, or used cooking oil, the right centrifuge setup helps produce high-quality biodiesel while minimizing waste. The industrial 3-phase centrifuge is a good example of advanced equipment that gives larger producers the automation, reliability, and flexibility they need to stay competitive.

Getting more oil isn’t just about pushing the machine harder; it’s about running it correctly, every single time.