Industrial Heavy Marine Fuel Oil Separation Centrifuge

Product Description

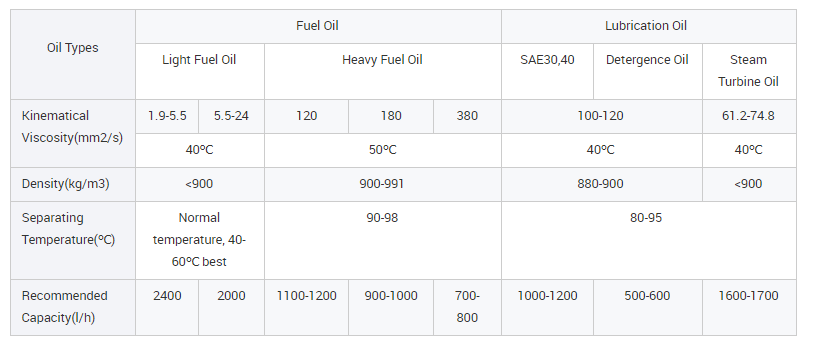

Fuel Oil Separator is mainly used to remove water and mechanical impurities(cat fines) from diesel oil, lubricating oil, heavy fuel oil(HFO) and other mineral oil in marine diesel engine unit and land-used diesel generator unit of power station so as to reduce wear of the diesel engine and other machine, and prolong engine life.

The model is also used to separate two unsolvable liquids with different specific gravity or remove small amount of solid particle from liquid.

Feature

1. The piston type slag removal and self cleaning automatically discharging.

2. Belt drive(No second tensioning required).

3. Full hydraulic discharge structure, quicker Respond and slag discharge more thoroughly.

4. Internally installed with three sets of programs applied to the Separation of HFO, LO and DO.

5. Automatically detection of water sealed water and slag discharge time.

6. Master the technology of ''no-gravity ring'' automatically adjusting the ''oil water interface'' for the first time in China after world famous brand.

7. Suitable for the separation of high viscosity(380cSt/50°C) and high density(~1010Kg/m3 /15 °C )HFO.

Working Principle:

Working Principle:

Disc separator is vertical centrifuge. The drum is installed on the upper side of the vertical shaft. Driven by the motor, it will rotate at a high speed through the gearing. Inside the drum there is a group of dish parts overlaying each other – disc. There is very small gap between the disc. Suspension (or emulsion) is fed into the drum through the inlet in the middle of the drum. When the suspension (or emulsion) flows through the gap between the disc, under the action of the centrifuge, the solid particles (or droplets) go down to the disc in the formation of sediment (or liquid layer). Along the disc surface, the sediment slides out of the disc and accumulates at the part with the largest diameter inside the drum. After the separation, the liquid is discharge out of the drum from the drain outlet. The role of the disc is to reduce the sediment distance of solid particles (or droplets) and enlarge the sediment area of the drum. With the disc inside the drum, the capacity of the separator is improved greatly. The solid gathering inside the drum is manually removed by taking apart the drum after power off, or discharges from the drum through the slag-off part with the separator power on.