1500kg/H Extra Virgin Olive Oil Production Line

Extra Virgin Olive Oil Production Line

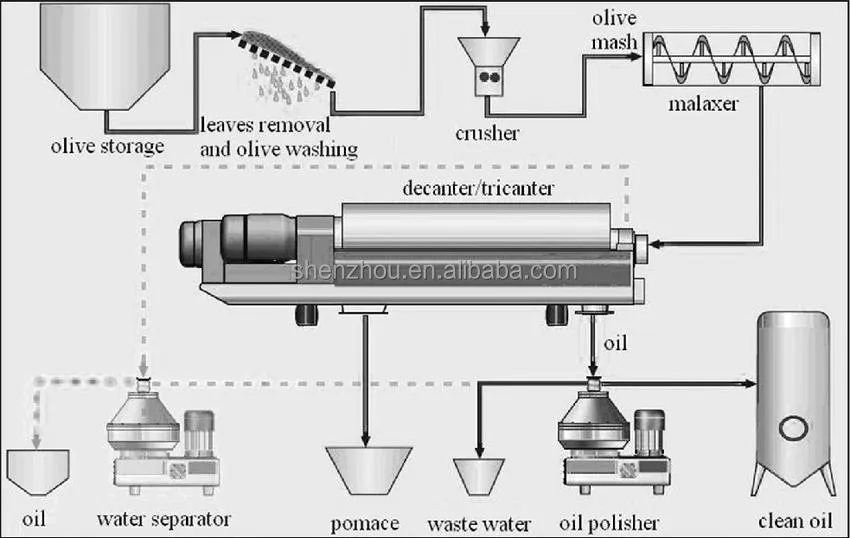

Generally,the whole system consists of the following 6 steps

1.- olive fruits reception and leaf removal system

2.- olive fruits washing system

3.- olive fruits crushing and paste malaxing system

4.- olive oil extraction system (2/3 phase optional)

5.- olive oil purification system

6.- olive oil storage and bottling system

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

All components such as decanter centrifuge and vertical separator are made in china!

Configuration List

S/N. | PROCESS EQUIPMENT | SPECIFICATION | POWER | QTY |

1 | WASHING MACHINE | FOOD GRADE SUS304 | / | 1 |

2 | AVOCADO DESTONER | FOOD GRADE SUS304 | / | 1 |

3 | PULP MALAXER TANK | FOOD GRADE SUS304 | / | 2 |

4 | DECANTER CENTRIFUGE | FOOD GRADE SUS304 | / | 1 |

5 | DISC SEPARATOR | FOOD GRADE SUS304 | / | 1 |

6 | CONTROL CABINET | CONTROL THE WHOLE LINE; CARBON STEEL | / | 1 |

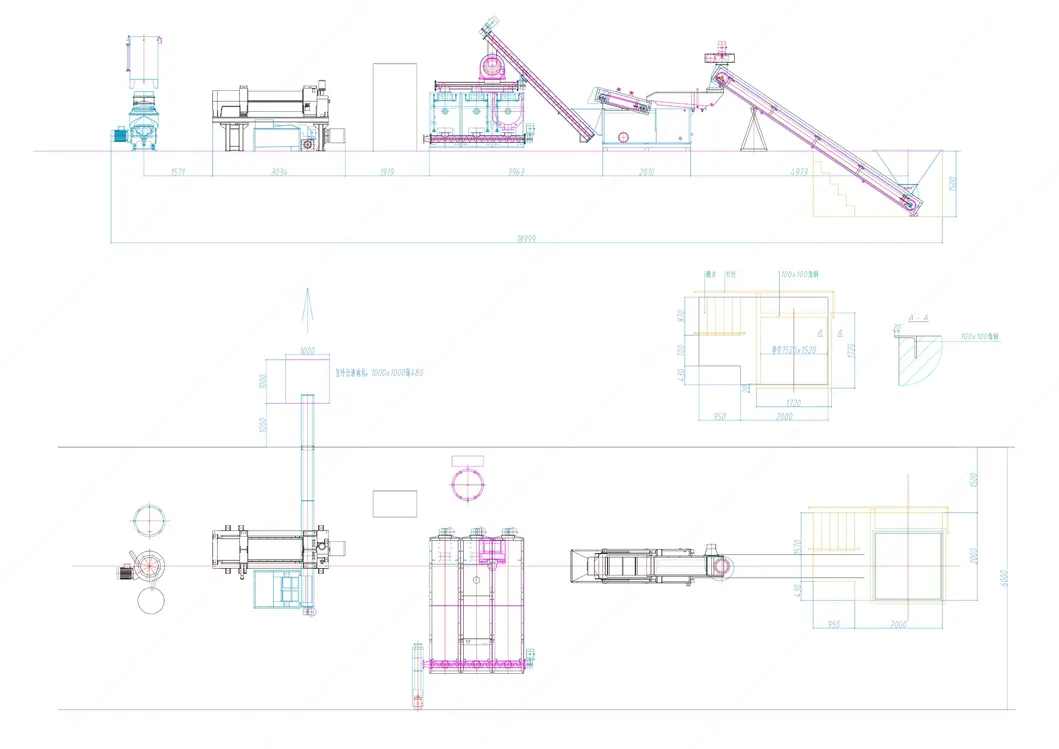

Process Drawing Process Description

Process Description

Storage&Transfer Process

The collected fruits shall be put into small baskets first and delivered to factory,The baskets will stack in the ventilate storage warehouse to avoid oxidation&fermentation phenomenon because of the overheat and bruise.

Fruit Washing Process

The olive fruits are conveyed into the washing machine,then are rinsed and washed to remove the dust under the function of strong water flow.The water is collected for recovery by circulation tank under the vibration sieve.

Crushing&Malaxing Process

After crushing,the olive fruit pulp will be pumped into the malaxer for further process. The oil drops will be released and merge into large drops which can be separated easily by centrifuge.

Pulp Malaxing Process

After crushing,the olive pulp will be pumped into the malaxer for further process. The oil drops will be released and merge into large drops which can be separated easily by centrifuge.

Centrifuge Extraction Process

After malaxing,the decanter centrifuge will be followd to separate the oil from pomace and water.During this process, 2 and 3 phase decanter centrifuge are available to meet production condition.

Oil Purification Process

After decanter,the oil still contains little moisure and impurities. Here a vertical disc separator is used to saparate the

impurities for final purified virgin olive oil.

impurities for final purified virgin olive oil.

Different Models for Choice

(The following capacity is based on the Olive fruits input)

SZ-500 | SZ--1000 | SZ--2000 | SZ--3000 | SZ--5000 | SZ--8000 |

500KG/H | 1000KG/H | 2000KG/H | 3000KG/H | 5000KG/H | 8000KG/H |

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave A Message

Welcome all who care engaged in the separation and filtration to work with us,and we are also looking for the qualified world wide agents to provide better service and deep marketing.

no data

Related Products

no data

Copyright © 2026 Shenzhou Machinery is a core subsidiary of Shenzhou Group | Sitemap